Tahoe Resources owns the high-grade Escobal silver deposit located approximately 70km south-east of Guatemala City. The mine also contains sizeable reserves of gold, lead and zinc.

The exploitation license for the mine was granted in April 2013 and underground development commenced in May 2011. Mining operations began in September 2013 and first shipment of silver-bearing metals concentrate was made in October 2013. Commercial operations started in January 2014. Approximately 500 construction jobs were created with the mine’s development.

Escobal Silver Mine is expected to produce approximately 20 million silver equivalent ounces a year during the first ten years of operation. Its mine life is estimated at 18 years.

Escobal mine geology, mineralisation and reserves

The Escobal deposit lies within the southern portion of the Motagua fault system. The southern side witnessed a series of Tertiary mafic volcanic eruptive events made up of dacitic, andesitic and basaltic flows. The events are separated by thin layers of fine to medium-grained clastic and tuffaceous sediments.

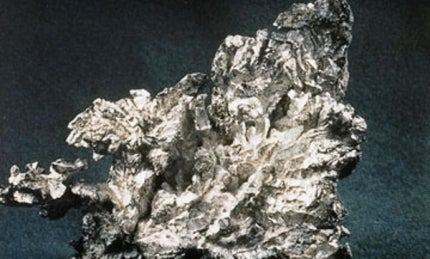

Silver-lead-gold-zinc mineralisation is contained in quartz veins, stockwork and breccia zones. The mineralisation is open at depth and to the east and west of the deposit. The eastern and western parts are covered by alluvium and post-mineral volcanic rocks.

As of 2012, the Escobal mine was estimated to contain indicated resources of 27.1 million tonnes of ore graded at 422g/t silver, 0.43g/t gold, 0.71% lead and 1.28% zinc. It is estimated to contain 367.5 million ounces of silver, 373,000oz of gold, 192,000t of lead and 347,000t of zinc.

Mining and processing at Escobal mine

Long hole stoping method is applied to extract ore from the Escobal underground mine. Longitudinal variant of stoping is being used in areas where the strike length is less than 15m and vertical variant for strike length more than 15m.

Ore is excavated using load-haul-dump (LHD) machines and transported to the process plant using AD45 Caterpillar trucks. The mined stope voids are backfilled with cement to enable recovery of the remaining material.

Related content

Moss Mine Gold-Silver Project, Bullhead City, Arizona, United States of America

Moss Mine Gold-Silver Project is located ten miles (16km) east of Bullhead City in Oatman Mining District of Mohave County in north-west Arizona.

Conventional crushing-grinding and froth flotation are applied at the Escobal processing plant. The run-of-mine material is processed and sized using primary, secondary and tertiary jaw crushers. It is then transported to a 4,500hp ball mill where the material is further ground to make it suitable for the flotation circuit.

The flotation circuit comprises lead and zinc flotation circuits, which produce a high-value gold, silver and lead concentrate, and lower-value zinc concentrate. The final lead and zinc concentrates are thickened, filtered and loaded into containers for shipment.

Flotation tailings are thickened, filtered and either dry stacked in a tailing impoundment area or transported to the paste backfill plant for further use in mine backfilling. Water from the tailing and concentrate dewatering will be treated and recycled for reuse in the process.

The major mining fleet comprises R1700 and R2900 Caterpillar LHD loaders, 45t Caterpillar trucks, Atlas Copco electric-hydraulic jumbos and Atlas Copco Simba drills.

Production and sale of metal concentrates

During 2013, the silver mine produced 220,000t of metal-bearing material, of which 159,000t were processed. A total of 2,723t of concentrate containing approximately 1.4 million ounces of payable silver were shipped and sold to third parties.

Construction and infrastructure at Escobal mine

Construction work for the underground mine began with the development of the east central and west central decline portals.

Major works included the commissioning of the processing facilities including the primary, secondary and tertiary crushing facilities, ball mill, zinc and lead flotation circuits, concentrate filtration, tailings thickeners and filtration and paste backfill plant, as well as the installation of other equipment.

Financing and contractors at Escobal mine

Tahoe obtained a $50m secured credit facility in June 2013 for developing the Escobal mine. The credit facility was extended by $25m in January 2014.

M3 Engineering, which conducted the PEA, was awarded the engineering, procurement and construction management (EPCM) contract. JDS Energy & Mining were contracted to manage the above ground mine construction.

.gif)