The Brunswick lead/zinc mine, located 35km southwest of Bathhurst, New Brunswick, was formerly owned and operated by Noranda. In June 2005, Noranda merged with its 59%-held subsidiary, Falconbridge, with the ‘new Falconbridge’ being taken over in mid-2006 by the Swiss-based company, Xstrata. Brunswick now operates within Xstrata’s zinc division, producing lead and zinc concentrates with byproduct copper, silver, gold, bismuth, antimony and cadmium.

Employing around 800 people, Brunswick treats about 3.6Mt/y of ore, and is the world’s largest underground zinc mine with a cumulative output to the end of 2005 of over 110Mt of ore. Its output is refined at the company’s Brunswick lead smelter and at the CEZinc refinery. The mine was to be depleted by the end of 2010. However, in the first quarter, Xstrata announced that operations will be extended by to 2011.

Geology and reserves

The ore is contained in up to ten massive sulphide lenses within folded and uplifted lead-zinc, pyrite and copper zones. The metals occur as extremely fine-grained mixtures of chalcopyrite, galena, sphalerite and pyrite, together with gold, silver and other metals.

At the end of 2009, proven reserves totalled 6.2 Mt grading 0.4% copper, 8.4% zinc, 3.4% lead and 104g/t silver. Probable reserves stood at 2.2Mt grading at 7.6% Zn, 3.0% Pb, 0.3% Cu and 84g/t Ag.

Mining method

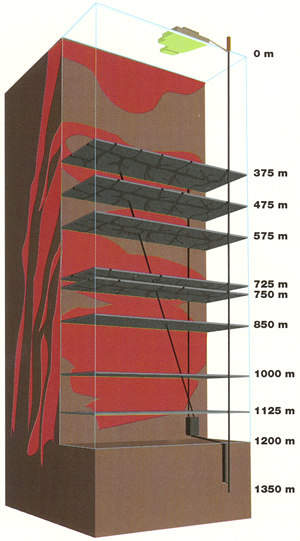

The 1,125m-deep mine is accessed by a vertical shaft and worked by two methods; the older cut-and-fill method allows the ore to be mined steadily from bottom to top and backfilled with waste rock, leaving a working platform. However, the more efficient open stoping is preferred. Pillars are removed later. Blasted ore is retrieved by remote-controlled load-haul-dump (LHD) machines for transport to ore passes leading to one of the three crushing plants. One recent innovation used is the ‘Weasel’, a unit that can be operated by remote control for drilling and charging blastholes in open stopes.

Each crusher has two 1,500t-capacity, run-of-mine ore storage silos. A jaw crusher and two gyratory crushers reduce the ore to minus 150mm before conveyance to the No.3 shaft silos for hoisting to surface in skips.

Processing

The concentrator design capacity is 10,500t/d of complex lead, zinc, copper and silver sulphide ore. During 2009, 3.3Mt of ore was treated in the mill with a zinc recovery rate of 88.43%. The head grade was around 8.59%. Production increased primarily due to the implementation of a zinc circuit stabilisation project that led to a 4% increase in zinc in concentrate.

The rod mill oversize is recycled through a ball mill before re-entering the hydrocyclones. The undersize pulp, containing sphalerite, chalcopyrite, galena, sphalerite/galena combined and gangue minerals, feeds the sequential flotation circuits to produce individual zinc, copper, lead and bulk sulphide concentrates. Zinc is recovered first, with the rougher tailings feeding the copper recovery stage.

Copper tailings proceed to lead upgrading and bulk concentrate recovery. Lead upgrading uses reverse flotation to float off pyrite, which is sent to the final tailings. The by-product is lead concentrate containing 40% lead. In the bulk circuit, combined lead and zinc is floated, producing a concentrate containing 39% zinc and 19% lead. The copper concentrate contains 23.5% copper and the zinc concentrate contains 52.5% zinc.

Concentrates are dewatered to 30–40% moisture. Vacuum filters reduce the water content in the zinc, lead and bulk concentrates to around 17%, with further kiln drying to 7% moisture, while the copper concentrate is dried using pressure filters.

Production during 2009 was 3.6Mt of ore, 275Kt of zinc in concentrate, 8,000t of copper in concentrate and 80,000t of lead in concentrate, plus 210t of silver in concentrate.

Transport

Copper and zinc concentrates are shipped to worldwide markets as raw concentrates. Lead and bulk concentrates undergo further refining in the company smelter at Belledune. The smelter separates out copper matte, antimony-lead alloys, silver-gold doré and bismuth alloys in successive steps.

Expansion

Recent developments have included the commissioning of a paste backfill plant to simplify the backfilling process underground, and the installation of an SAG mill to give better grinding performance in the preparation of flotation feed.

Environment

The Brunswick commitment to the wellbeing of communities while sustaining the natural environment is demonstrated by the Daly Point wetland project, the Nepisiquit salmon enhancement project and the company’s environmental awareness programme.

Acid mine drainage is now treated in the new high-density sludge treatment (HDST) plant at the No.12 site. A high-density lime (HDL) treatment process is used to reduce the acidity and water content.