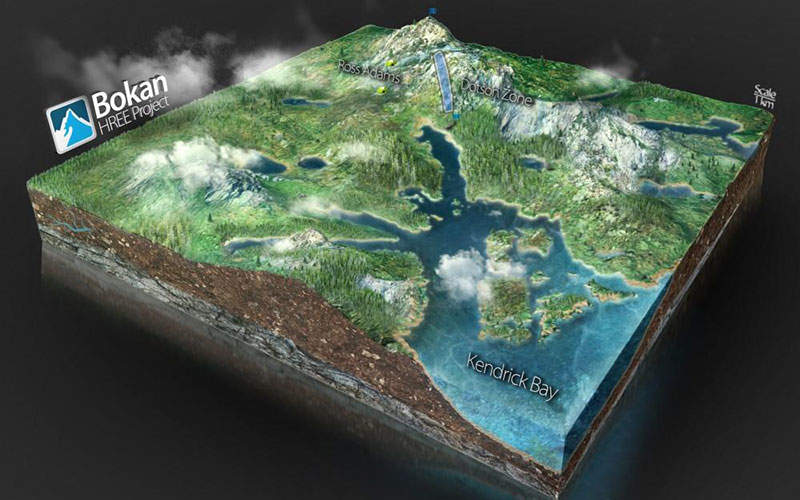

The Bokan – Dotson Ridge Rare Earth Element (REE) Project, covering an area of approximately 3,000ha, is located on the southeast flank of the Bokan Mountain, roughly 60km southwest of Ketchikan, Alaska.

Ucore Rare Metals, the project’s owner, plans to invest $221m. The project is being supported by a $145m bond funding from the State of Alaska through its Alaska Industrial Development Export Authority (AIDEA).

The preliminary economic assessment (PEA) report study for the rare earth element project was completed in January 2013. Ausenco Engineering Canada is currently compiling the feasibility study (FS) for the project.

The project site is accessible by boat, floatplane, barge, and helicopter, and partly by an existing 4km gravel road. The site is claimed to be the world’s only REE project with immediate deep water access. The initial mine life is estimated to be 11 years.

Bokan – Dotson Ridge REE project geology

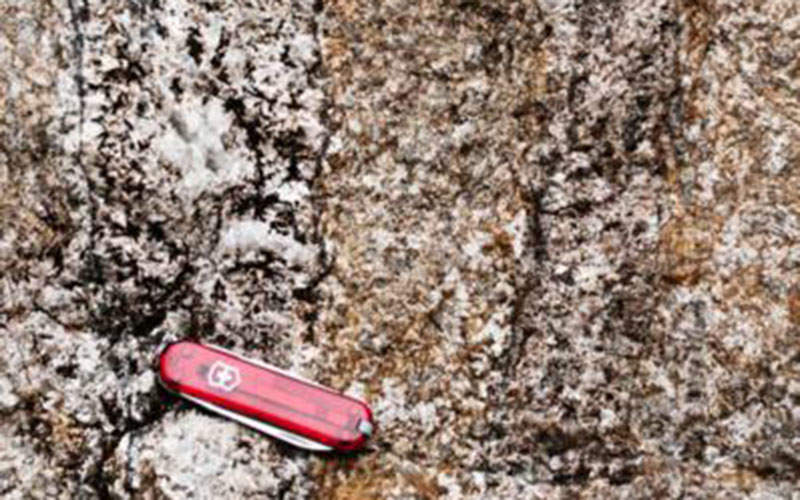

The project involves the development of the Dotson deposit, which hosts three types of REE mineralised west-northwest-striking and steeply-dipping vein-dike systems, including irregular structurally controlled pipes, shear zone-related veins, and pegmatitic or felsic dikes.

The mineralisation is related to the circular Mesozoic peralkaline inclusive granitic complex, known as the Bokan Mountain Granite, and the mineralised system is exposed at the surface for a strike length of 3.5km.

Reserves of Ucore Rare Metal’s flagship project

The project is estimated to hold indicated resources of 4.787 million tonnes (Mt) grading 0.602% TREO at a cut-off grade of 0.4% TREO, and inferred resource of 1.050Mt grading 0.603% TREO at a cut-off grade of 0.4% as of May 2015.

The project is touted to hold the highest grade NI 43-101-compliant heavy rare earth elements (HRRE) resource in the US, which ranks second among the world’s biggest rare earth metal producers. Approximately 40% of the project’s total rare earths oxide (TREO) resource is HRRE.

Mining and processing at the southeast Alaskan REE mine

The mining method envisaged for the project is blasthole stoping with cemented backfill. The underground mine will be accessed through a 4.5m-wide, 4.5m-high and 289m-long decline and mined at a rate of 1,500t a day.

The processing plant will incorporate a physical beneficiation circuit integrating dual-energy X-ray transmission (DEXRT) sorters and magnetic separators, a leaching circuit using a nitric acid leach process, and a rare earth oxide (REO) separation circuit.

The most probable separation process for the project is a molecular recognition technology (MRT) circuit using the proprietary SuperLig hydrometallurgical process, owned jointly by Ucore and IBC Advanced Technologies.

The technology has delivered heavy rare earth concentrates exceeding 99% purity level using the feedstock from the Bokan deposit and is being piloted at SepraMet, IBC’s wholly-owned subsidiary’s site in Houston, Texas, under a project dubbed as SuperLig One, to meet the Bokan REE project requirements.

The REO production from the mine is estimated to average 2,250tpa during the first five years, with 95tpa of dysprosium oxide, 14tpa of terbium oxide and 515tpa of yttrium oxide produced.

Infrastructure for the US REE project

The power requirements for the project will be met through two main 2MW liquified natural gas (LNG) generators, and a 2MW auxiliary LNG generator, whereas the required water will be sourced from underground and existing streams at the site.

Other infrastructure at the site will include permanent accommodation and office buildings, a paste backfill plant, a tailings and mine water management facility (TMWMF), a waste rock management facility (WRMF), a water treatment plant, a sewage treatment plant, access and on-site roads, ventilation systems, and a compressed air plant.

Key players involved

The PEA for the project was compiled by Tetra Tech, who collaborated with Stantec for the underground mine design, Knight Piésold for the tailings management facility, Hazen, CommodasUltrasort (now TOMRA Sorting) and IntelliMet for the metallurgical test work, Lyntek for the process flowsheet, and Aurora Geosciences for the mineral resource estimate and environmental studies.