Carpenter Technology. has patented a duplex stainless steel alloy with specific composition ranges, including chromium, molybdenum, nickel, manganese, copper, nitrogen, carbon, cobalt, silicon, tungsten, and iron. The alloy consists of 40%-60% ferrite and 60%-40% austenite, suitable for various forms like cast, wrought, or powder. GlobalData’s report on Carpenter Technology gives a 360-degree view of the company including its patenting strategy. Buy the report here.

According to GlobalData’s company profile on Carpenter Technology, Powder bed fusion was a key innovation area identified from patents. Carpenter Technology's grant share as of January 2024 was 55%. Grant share is based on the ratio of number of grants to total number of patents.

Duplex stainless steel alloy with specific composition ratios

See Also:

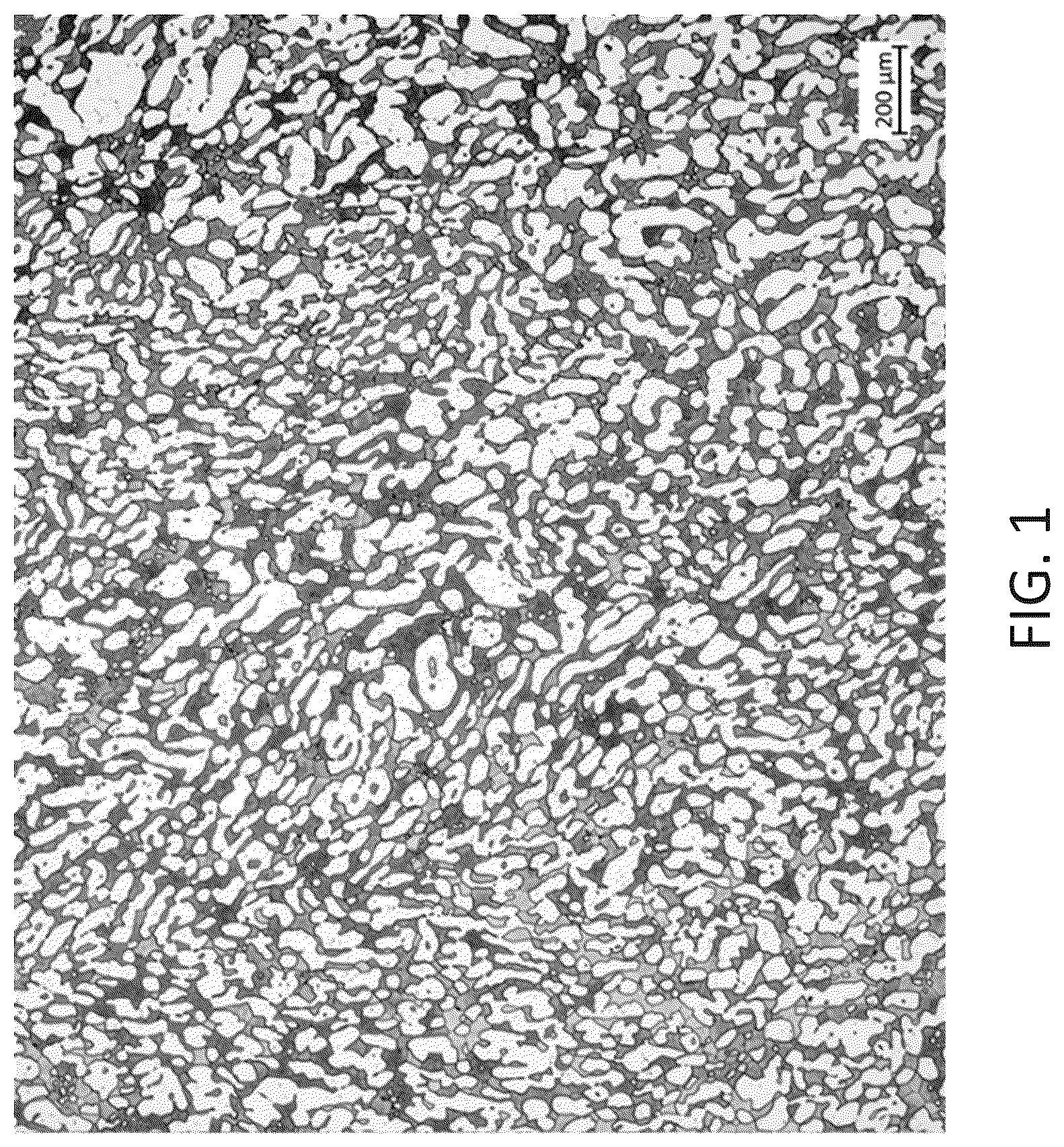

A patent application (Publication Number: US20240026509A1) discloses a novel duplex stainless steel alloy with specific composition ranges. The alloy comprises chromium, molybdenum, nickel, manganese, copper, nitrogen, carbon, cobalt, and iron, with precise weight percentages to achieve a balance of ferrite and austenite phases. The alloy's nickel equivalent and chromium equivalent values are crucial for its properties, ensuring a specific combination of elements for optimal performance. The patent also covers variations of the alloy for different applications, including cast and wrought steel forms, with specific mechanical properties such as yield strength, ultimate tensile strength, elongation, and pitting resistance.

Moreover, the patent application extends to the production of duplex stainless steel alloy powder for additive manufacturing processes. The powder composition aligns with the alloy's specifications, allowing for the creation of complex geometries with enhanced properties. The method for forming the alloy and powder involves melting a mixture of elements, followed by additional processes like forging and heat treatment for solidified metal alloy. The atomization of the molten metal stream in a high-pressure gas environment further refines the powder for additive manufacturing applications, ensuring quality and consistency in the final product. Overall, the patent application presents a comprehensive approach to developing and utilizing duplex stainless steel alloys with tailored compositions and manufacturing methods for various industrial applications.

To know more about GlobalData’s detailed insights on Carpenter Technology, buy the report here.

Premium Insights

From

The gold standard of business intelligence.

Blending expert knowledge with cutting-edge technology, GlobalData’s unrivalled proprietary data will enable you to decode what’s happening in your market. You can make better informed decisions and gain a future-proof advantage over your competitors.