Austin Powder: Your partner in large-scale mining excellence

Mining excellence through precision, innovation, and sustainability

Austin Powder specializes in providing tailored blasting solutions for large-scale mining operations. With decades of experience, we deliver innovative products and services designed to maximize productivity while ensuring safety and environmental stewardship. Our comprehensive offerings include advanced bulk explosives, electronic initiation systems, and cutting-edge digital solutions like the Paradigm Blast Modeling Software and Global Blast Report. We are committed to being your trusted partner in achieving operational excellence and sustainability in the mining sector.

Customized blasting solutions

Tailored blasting solutions for optimal performance

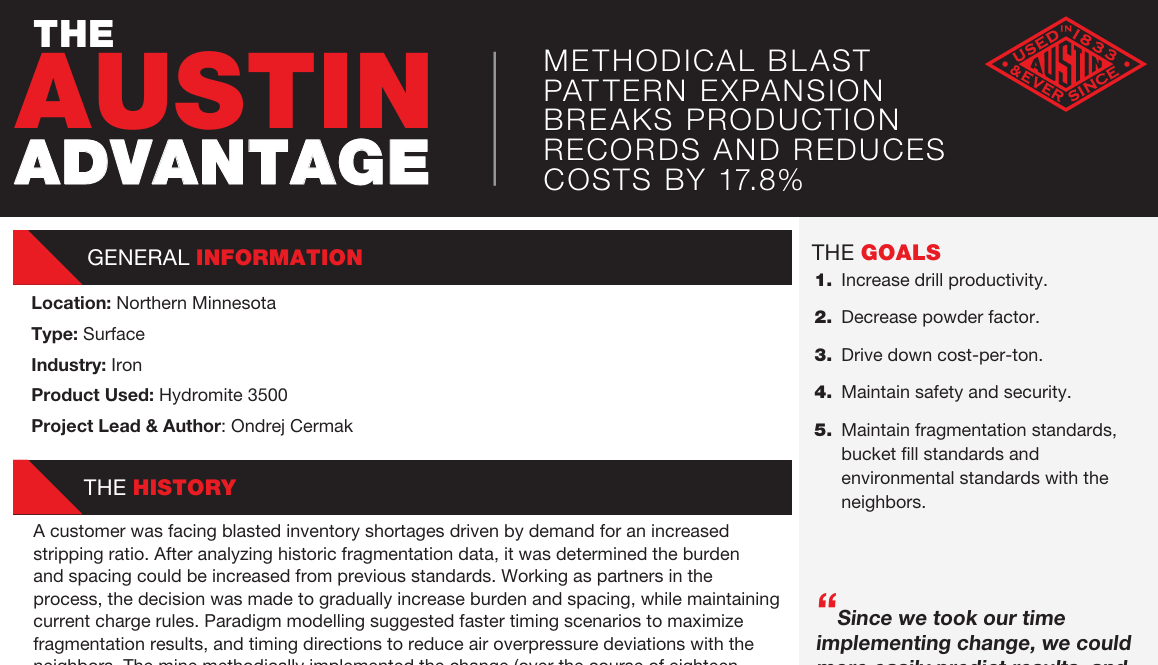

At Austin Powder, we understand that each mining operation is unique, which is why we offer customized blasting solutions that cater to specific project requirements. Our extensive range of bulk explosives, including Austinite and Hydromite, are engineered for reliability and efficiency. These products are designed to perform optimally in both dry and wet conditions, ensuring effective rock fragmentation and minimizing environmental impact.

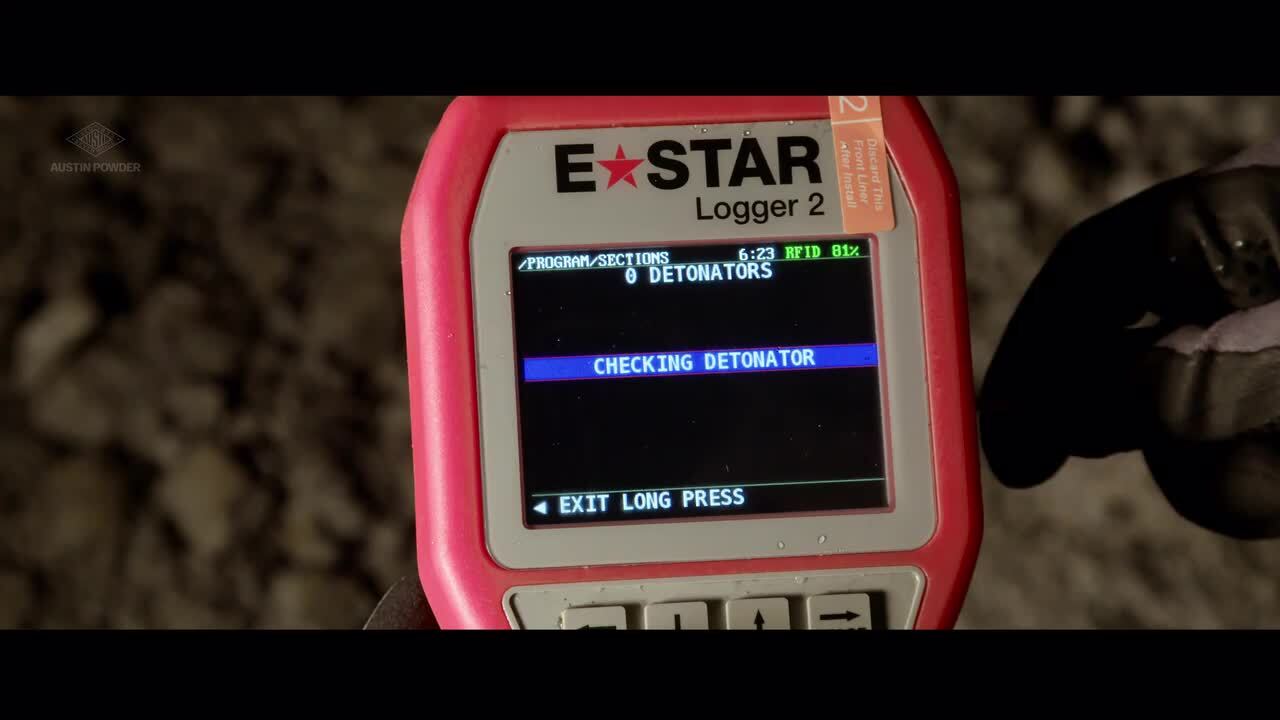

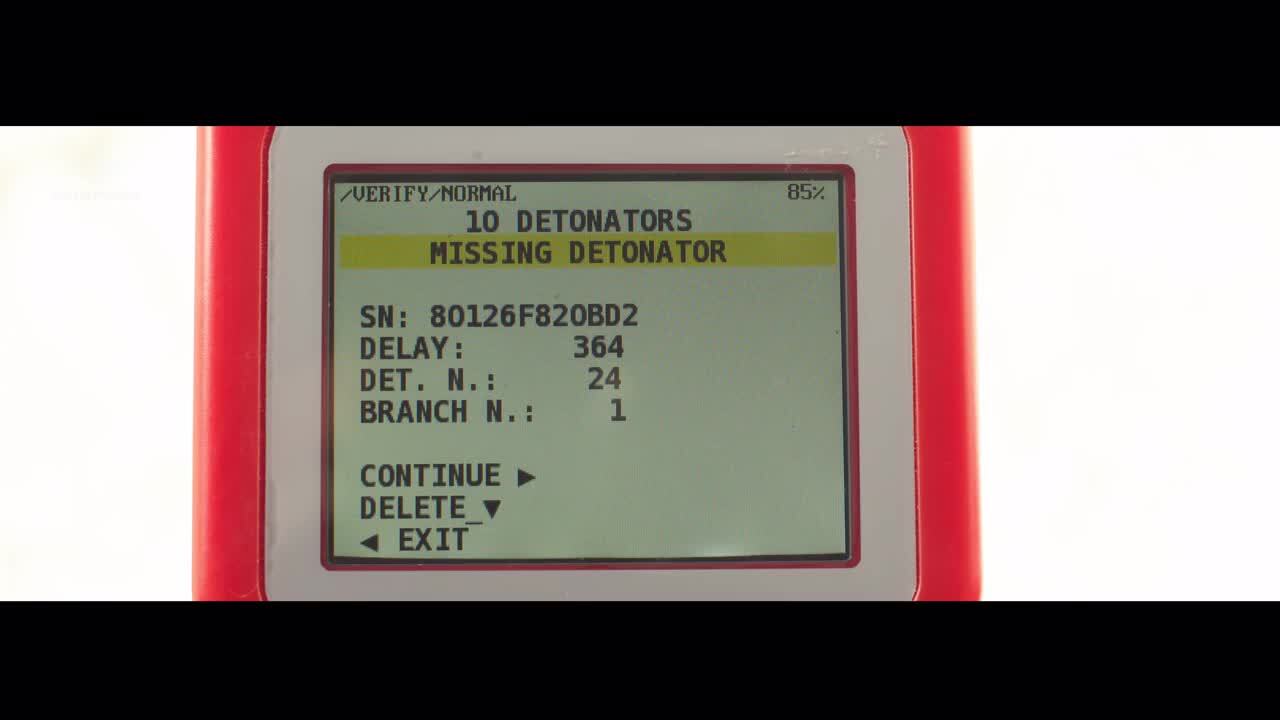

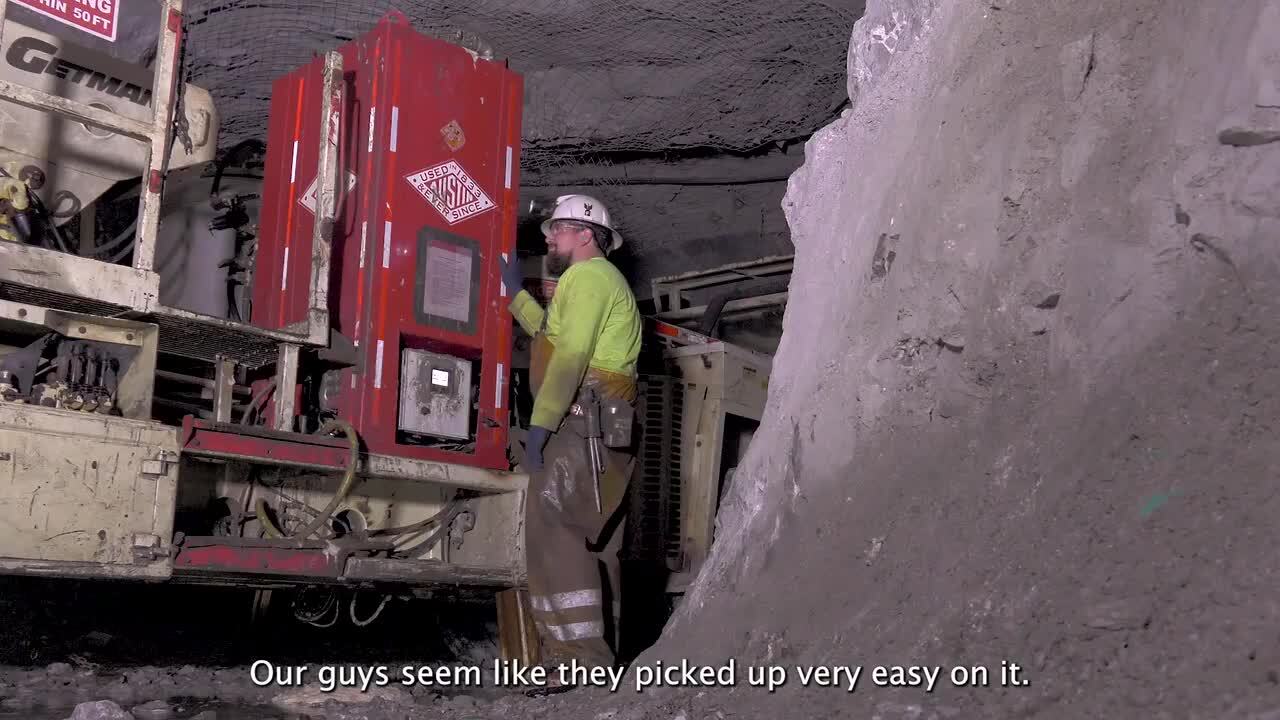

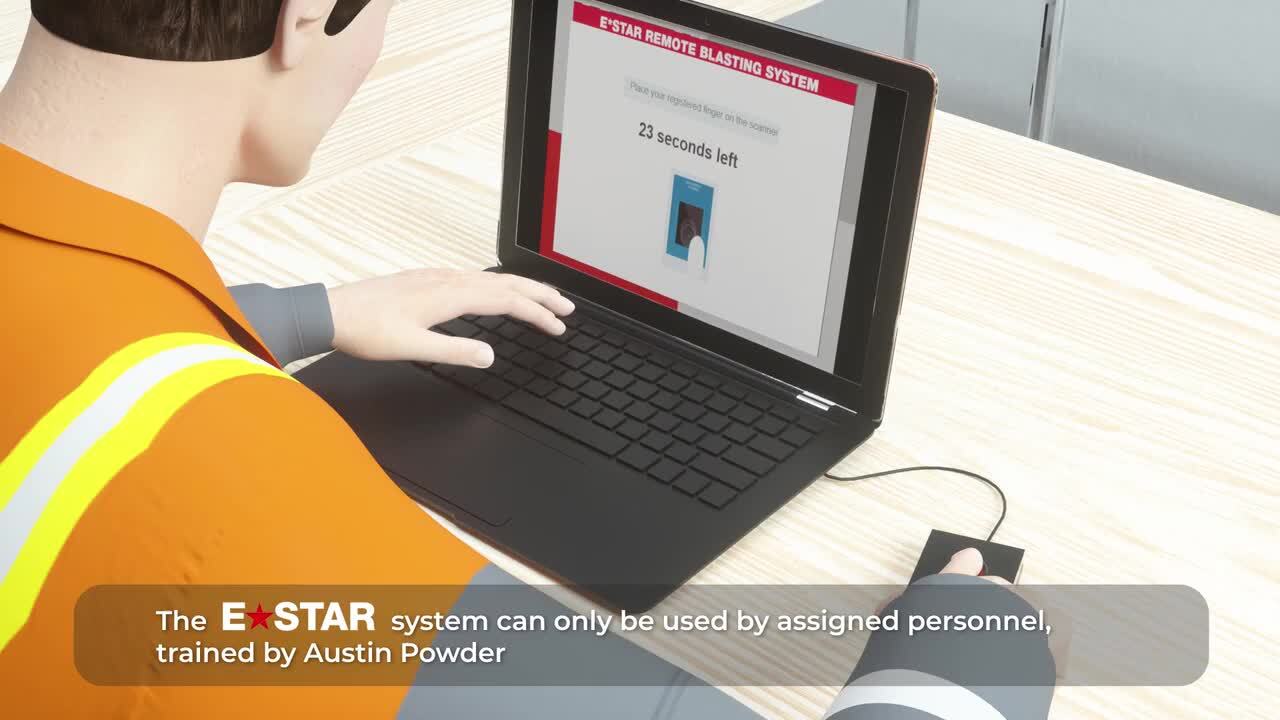

Our E*STAR Electronic Initiation System represents the forefront of blasting technology. This system provides unparalleled precision and flexibility, allowing for programmable control and real-time communication. With E*STAR, you can achieve superior fragmentation, reduce environmental impact, and enhance operational efficiency. Our commitment to safety is reflected in the rigorous testing and quality assurance processes that every detonator undergoes, ensuring compliance and consistent results.

Advanced digital solutions

Innovative software for predictive blast optimization

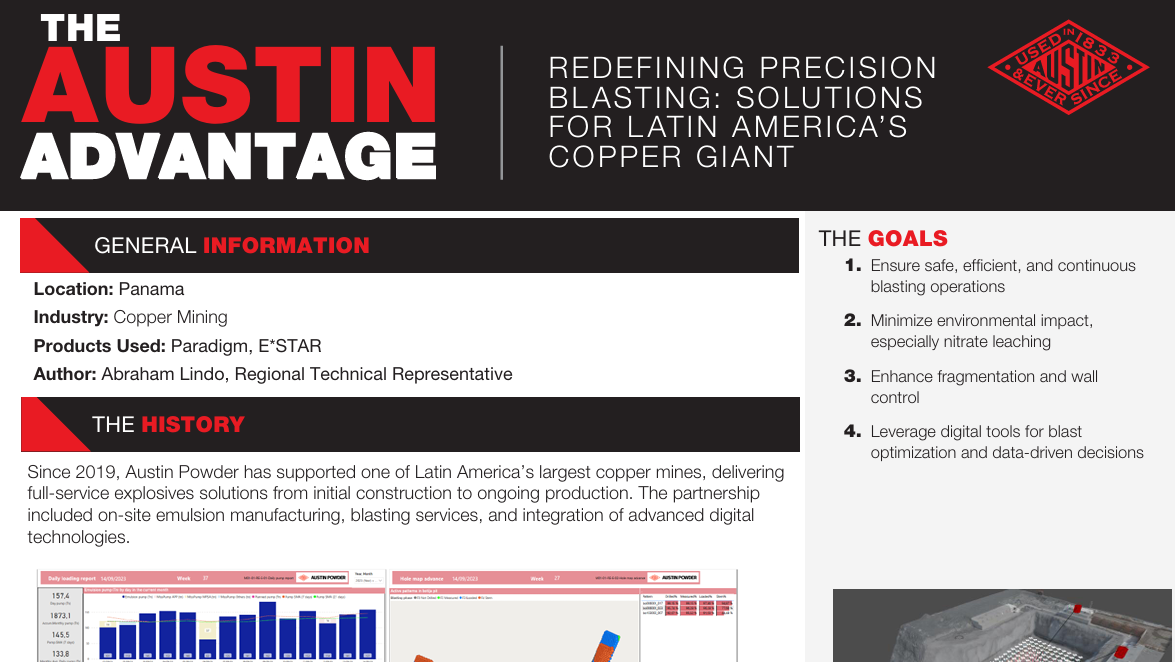

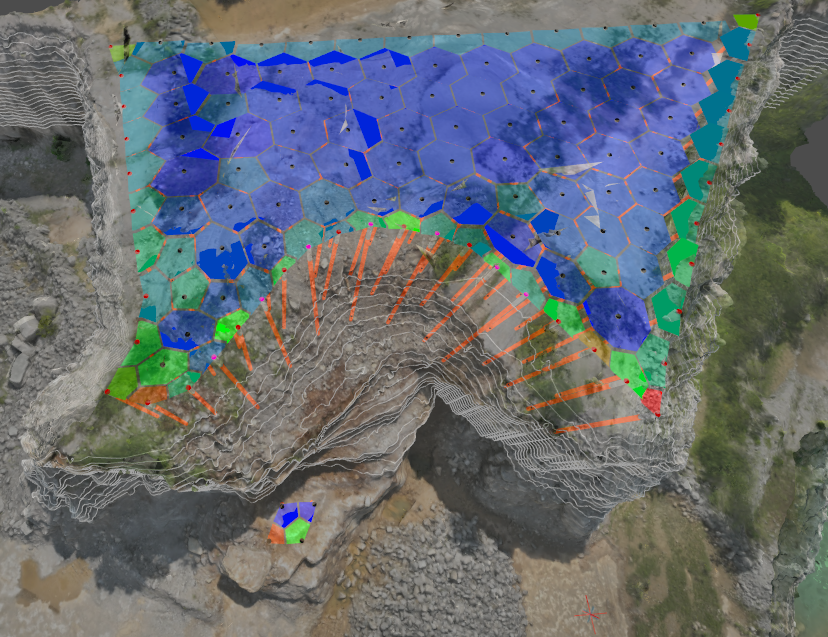

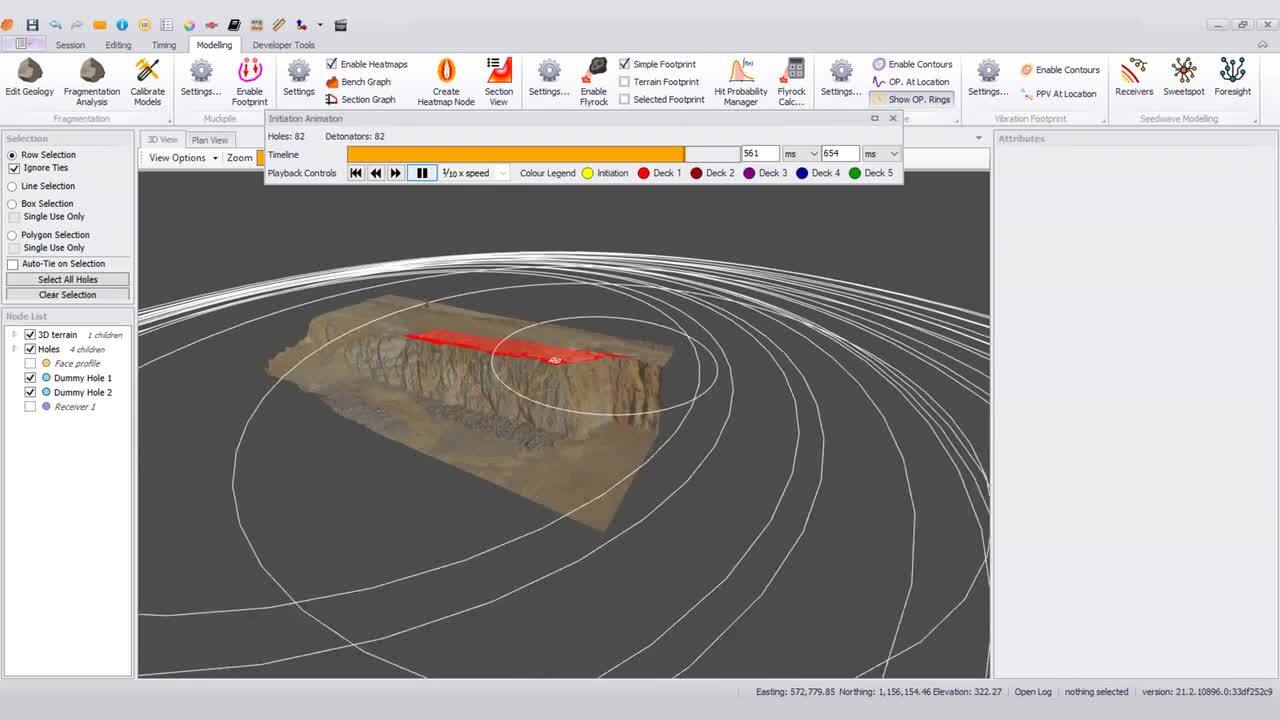

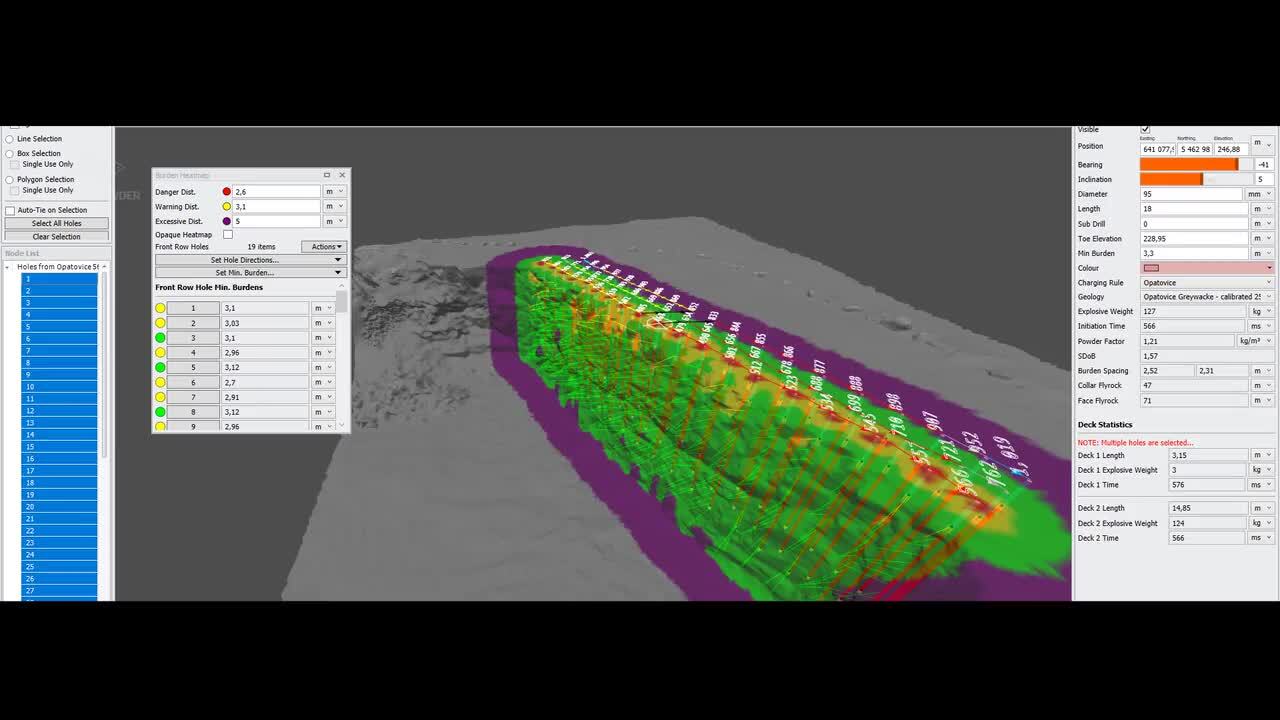

Austin Powder’s digital solutions, including the Paradigm Blast Modeling Software and Global Blast Report, are designed to enhance the efficiency and safety of blasting operations. Paradigm offers predictive blast optimization through 3D modeling and real-time data analysis, enabling precise control over outcomes such as fragmentation, vibration, and flyrock. This advanced software is essential for both surface and underground mining operations, helping to ensure regulatory compliance and improve overall performance.

The Global Blast Report (GBR) is another key tool in our digital arsenal. This sophisticated blast reporting software standardizes documentation across international operations, generating multilingual and jurisdiction-specific reports. GBR enhances communication with clients and authorities, ensuring that all blasting activities meet regulatory requirements. By integrating GBR with Paradigm, we facilitate seamless data flow from design to execution, improving collaboration and decision-making across teams.

Commitment to sustainability

Innovative products for sustainable mining practices

Austin Powder is dedicated to sustainability and innovation in the mining industry. Our product portfolio includes eco-friendly solutions designed to minimize environmental impact while maintaining exceptional performance. We are proud to lead the industry with our lead-free detonators, which comply with evolving regulations and significantly reduce environmental risks associated with traditional explosives.

Our commitment to sustainability extends to our research and development initiatives, where we focus on creating products that align with our global strategy for environmental stewardship. For instance, our ongoing projects aim to quantify NOx emissions from blasting using drones, enabling us to optimize techniques and further reduce our environmental footprint. By prioritizing sustainable practices, we support mining companies in achieving their sustainability goals while positively impacting local communities.

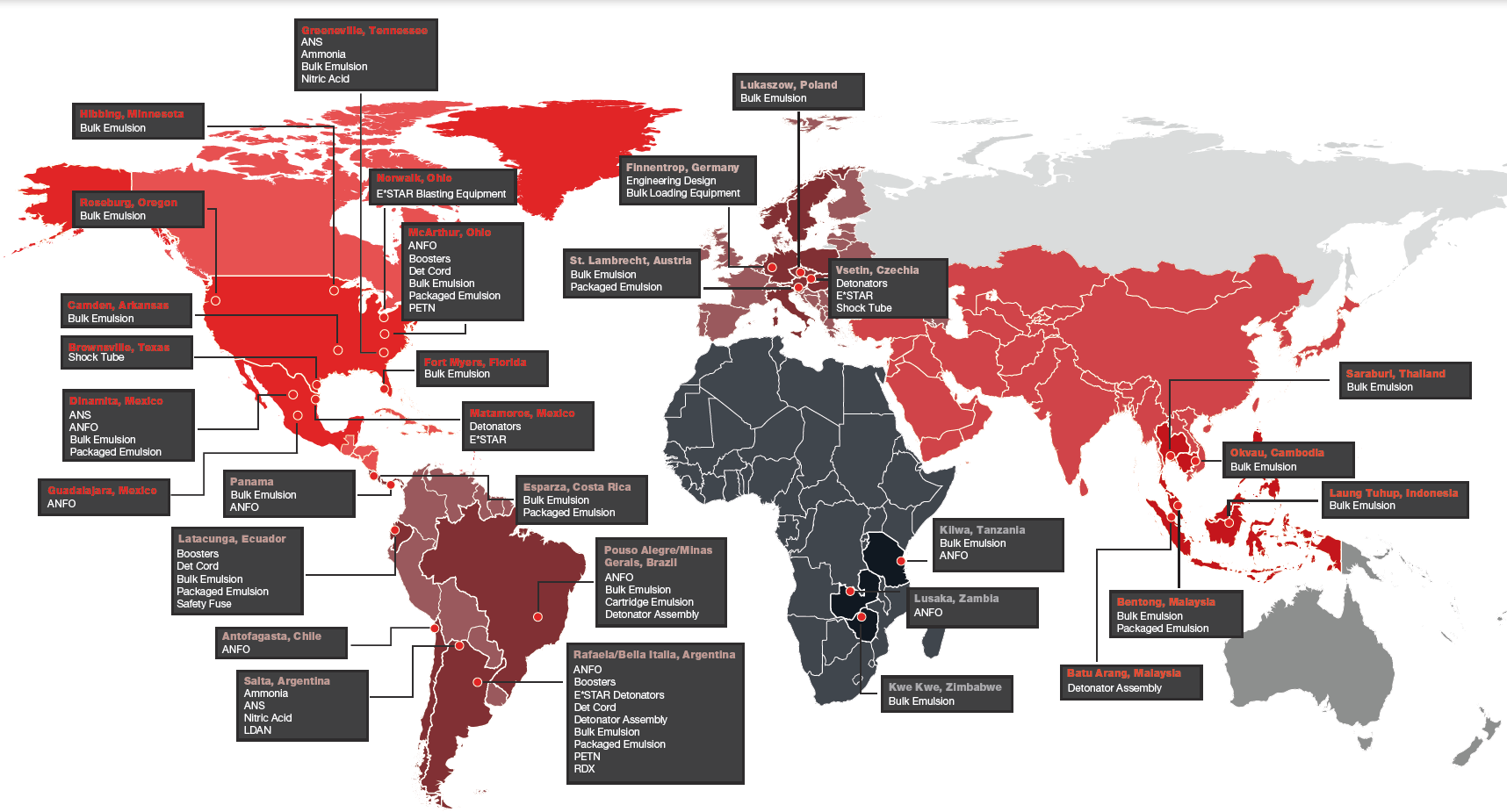

Global presence and expertise

Providing blasting solutions worldwide

Austin Powder boasts a strong global footprint, with operations in key markets across the Americas, Europe, Asia, and Africa. Our extensive geographic reach allows us to provide advanced customized blasting solutions that adapt to regional needs. Established in 1833, we have built a reputation for excellence in the explosives industry, serving various sectors with our innovative products and services.

Our dedicated teams of experts are committed to delivering responsive support and strong customer focus. We leverage industry-leading technologies and methodologies to ensure that our clients receive the best possible blasting solutions tailored to their specific needs. Whether you are operating in the United States, Canada, Latin America, Europe, or Asia, Austin Powder is your trusted partner in large-scale mining excellence.

Call to action

Get in touch for tailored blasting solutions

If you are looking for reliable and innovative blasting solutions for your large-scale mining operations, look no further than Austin Powder. Please use the form above to send us your business inquiry, and let us help you achieve your mining goals with precision and sustainability.

Company history

Austin Powder has been a leader in the explosives industry since its establishment in 1833. With a rich history of innovation and commitment to safety, we have evolved to meet the changing needs of the mining sector.

Our decades of expertise have positioned us as a trusted partner for large-scale mining operations worldwide, and we continue to strive for excellence in every aspect of our business.