Adaptive AI Model Training and AI-Led Condition Monitoring

Industrial assets in mining and heavy industries face extreme operating environments such as heat, dust, vibration, and high mechanical loads.

MOVUS helps industrial environments and critical mining teams keep their equipment healthy, reliable, and running at its best.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

MOVUS helps industrial environments and critical mining teams keep their equipment healthy, reliable, and running at its best. We combine 24/7 visibility, AI-driven diagnostics, and practical support for prescriptive maintenance which gives you early warning of issues long before they turn into breakdowns, safety risks, or production loss.

From our base in Brisbane Australia, we started with a simple idea: if you can see how an asset is behaving in real-time, you can catch problems early and avoid unnecessary waste. Today, that idea has grown into a scalable asset-health platform used across Australia and beyond which is helping essential machinery run reliably in harsh, high-pressure conditions.

Our sensors work alongside a powerful AI platform which is backed by our engineering team to validate and give you clear visibility of asset health across your fleet. No noise. No guesswork. Just simple, actionable insights that help your people make better decisions and extend the life of critical equipment.

We’re not here to drown you in data. We’re here to help you prevent failures, reduce downtime, and build a more sustainable, reliable operation on asset at a time.

At MOVUS, we believe industrial assets can run better, last longer, and use fewer resources when teams have the right information at the right time.

Everything we do is built around one idea: when you can see how an asset is behaving, you can act early, prevent waste, and make smarter decisions with confidence.

Our vision

A future where every machine operates as part of a more sustainable, reliable ecosystem. By reducing waste, improving efficiency, and extending the life of critical equipment, we’re helping industries run in harmony with their environment without adding complexity.

Our mission

To turn complexity into clarity.

We bring together real-time sensing, AI-backed diagnostics, and human expertise so teams can understand what’s happening, why it’s happening, and what to do next. We do this to help organisations prolong asset life, avoid downtime, and create long-term value across their operation.

MOVUS was founded in 2015 Brisbane Australia with a clear goal: make asset health simple, accessible, and reliable. What started as a smarter way to see how a machine is behaving has grown into a full asset-health ecosystem trusted across mining and industrial environments that has been shaped across a decade of innovation:

What began as a single vibration sensor is now a complete asset-heath ecosystem built to help industries make better decisions, avoid downtime, and operate more sustainably.

Industrial and mining environments demand reliability, and the cost of even minor failures can be significant. MOVUS helps teams shift from reactive firefighting to proactive, planned maintenance with solutions built for modern challenges.

Unplanned downtime

Unexpected failures disrupt production, delay schedules, and can cost thousands per hour. MOVUS provides early warning of vibration, temperature, and current anomalies, backed by diagnostics that flag developing faults weeks before they turn into breakdowns.

Data overload

Many sites already collect data, but don’t have the time to validate alarms or work out what matters. MOVUS delivers AI-driven insights that are validated by our engineering team and paired with clear prescriptive recommendations, so you know exactly where to focus.

Skills shortages & team pressure

Maintenance teams are stretched, and specialist expertise is hard to find. MOVUS automates routine monitoring and analysis, giving smaller teams the ability to manage larger fleets with prioritised insights and fewer manual checks.

Remote or hard-to-access assets

Large distances, hazardous areas, and remote infrastructure make regular manual inspection impractical. Our wired and wireless sensors provide continuous visibility without the travel time, helping you monitor assets safely, cost-effectively, and around the clock.

Reactive and calendar-based maintenance

Servicing based on fixed schedules leads to unnecessary work, or worse, missed early-stage faults. With continuous diagnostics, MOVUS helps identify imbalance, misalignment, bearing wear, and other issues long before failure.

Restricted machine data access

OEM systems often lock down data or make integration difficult. MOVUS gives you open, secure API access to both raw and processed data, enabling full transparency and seamless integration with your enterprise systems.

Smarter monitoring + practical outcomes

We’re not here to drown you in charts or dashboards. We deliver clarity with the right information at the right time, so you can act with confidence.

Real-time asset health visibility

Our sensors monitor vibration, temperature, and current around the clock, giving you a clear, real-time picture of equipment behaviour across your fleet.

AI + human expertise

Our diagnostics combine machine-learning, trained on industrial data with validation from our in-house experts. You get insights you can trust, complete with prescriptive actions, all without the noise or guesswork.

From rapid wireless deployment to rugged, high-fidelity wired options, our hardware is built to suit a wide range of industrial conditions.

FitMachine: Wireless vibration, temperature, and speed insights for near real-time visibility.

FitPower: Current and energy monitoring to spot abnormal load, inefficiencies, or emerging faults.

vEdge: Wired MEMS vibration + ultrasonic sensing + magnetometer for early-stage fault detection.

vSense: Triaxial and uniaxial piezoelectric sensors for detailed vibration analysis in extreme environments.

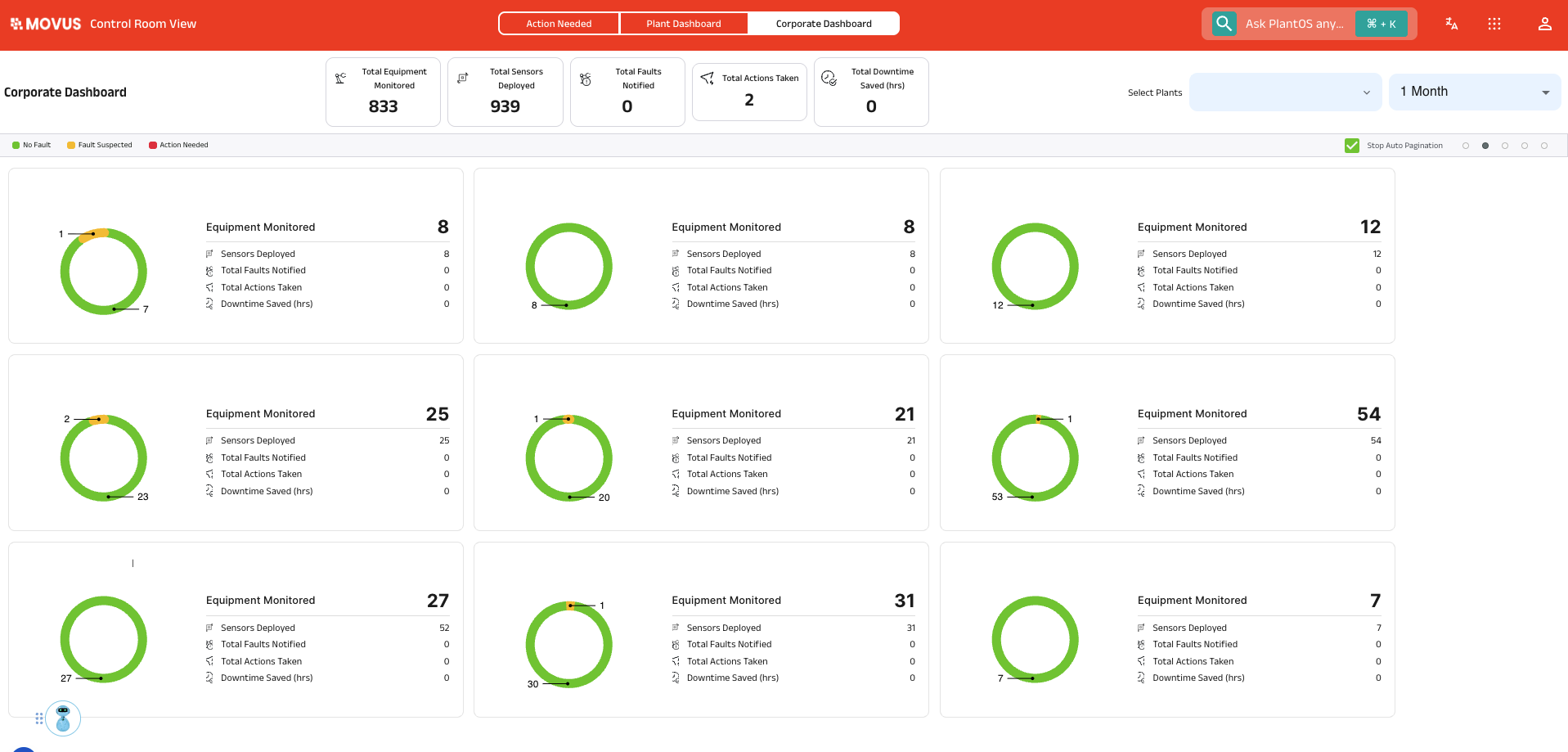

PlantOS brings the MOVUS ecosystem together. It centralises monitoring, diagnostics, fault identification, and prescriptive maintenance insights into one intelligent hub.

With specialised dashboards at plant, line, or machine level, PlantOS helps teams:

This is where data becomes decision, and where maintenance strategies evolve from reactive to truly prescriptive.

Across mining, manufacturing, food processing, and utilities, MOVUS customers consistently report measurable, repeatable improvements in asset reliability and maintenance performance:

These results reflect what happens when real-time visibility, AI-backed insights, and expert validation work together to support maintenance teams every day.

As industries push for greater efficiency, safety, and sustainability, the need for accurate, real-time equipment insights has never been more important. MOVUS continues to evolve its platform, sensor range, and AI models to meet these demands and help organisations cut waste, prevent failures, and extend asset life with confidence.

We’re here to support a future where every machine has a voice, every insight drives action, and every decision is backed by clear, practical intelligence.

Industrial assets in mining and heavy industries face extreme operating environments such as heat, dust, vibration, and high mechanical loads.

Fans and blowers are vital across process industries to move and regulate air for production and safety.

Ball mills are critical production assets in industries such as cement, mining & metals, steel, and fertilizers, where they grind ores, clinker, coal, and other raw materials into fine powders.

Conveyors are critical to bulk material handling in industries such as mining & metals, cement, power, fertilizer, and ports, moving large volumes of materials where a single failure can stop production, create safety risks, and cause major financial losses.

Crushers are essential, high-wear assets in heavy industries (mining, cement, metals, power) that reduce large raw materials for downstream processing.

Pumps are critical across process industries, heavy industry, and mining/metals because they enable essential operations such as cooling-water circulation, slurry transport, chemical/fertilizer fluid circulation, and hygienic food & beverage processing.

Paper manufacturing relies on asset-intensive, rotating machinery that runs in harsh conditions (high temperature, humidity, and loads), making equipment prone to early degradation and unexpected failures.

We’ll be attending the Total Plant Maintenance Conference 2026 in Melbourne this March to share how our prescriptive AI is helping plant teams make clearer decisions and improve throughput under real operating conditions.

MOVUS has announced the release of FitMachine 3XT EX, a wireless vibration and temperature sensor certified for use in hazardous industrial environments, with availability scheduled for February 2026.

Your smart, all-in one equipment monitoring solution

Your smart, industrial-grade vibration monitoring solution

Non-Intrusive Power Monitoring Solution

MOVUS is not just a sensor company. We provide end-to-end monitoring solutions that help teams move from basic visibility to confident, action-led maintenance decisions.

Wired MEMS vibration + ultrasonic sensing + magnetometer for early-stage fault detection.

Triaxial and uniaxial piezoelectric sensors for detailed vibration analysis in extreme environments.