Aventurine Engineering

Cost-Estimation Programs for Underground, Surface and Placer Mines

Subscribed

You have successfully submitted your enquiry. Someone from our company will respond ASAP

About Us

Aventurine Engineering designs and produces software used by cost estimators in the minerals industry. Our Sherpa line of programs is designed to estimate the capital and operating costs associated with underground, surface and placer mines, and we have recently released a program designed specifically to estimate the costs of reclaiming mine sites.

Aventurine also maintains and markets Apex economic analysis software for mining projects.

Engineering-based cost-estimation programs for mines

Sherpa cost-estimation software programs’ algorithms are engineering-based (as opposed to statistic-based). The software calculates costs in the same way that you would yourself, if you had the time.

Sherpa calculates and suggests specifications for the production and ancillary equipment fleets. It also determines workforce requirements, staff needs and supply consumption rates, and (using standard engineering calculations and relationships) provides specifications for buildings and ancillary facilities.

Customisable cost-estimation software for mines

The programs handle up to six separate production segments, or phases, which may be spread over a mine life of up to 25 years. Almost all input variables can be altered from one production segment to the next. Items such as daily production rates, stoping or excavation methods, development requirements, wages, salaries, supply prices, equipment types and sizes, and a host of other project parameters can be changed as necessary to meet your needs. Itemized cost results are reported in a cash-flow format.

Quick estimates can be based solely upon minimal project information (e.g., reserves, production rates, and haul profiles). Sherpa suggests values for all necessary engineering parameters, including items such as hole loading factors, material densities, explosive types, bench heights, stope dimensions, and development requirements. If you instruct it to do so, the program will then proceed to estimate all pertinent costs with no further input.

For more detailed estimates, experienced estimators can overwrite any or all of Sherpa’s suggested engineering parameters by simply typing in new values. Equipment, supply and manpower requirement values suggested by the program may also be overwritten. This feature allows you to incorporate your experience directly into the software algorithms.

Easy-to-use cost-estimation programs for mining personnel

Our easy-to-use cost-estimation programs for mining personnel are fully menu-driven, Windows-based applications in which all screens are carefully designed for clarity. Every screen is accessible from a main menu. Help screens are also provided for each entry.

Economic analysis software for mining projects

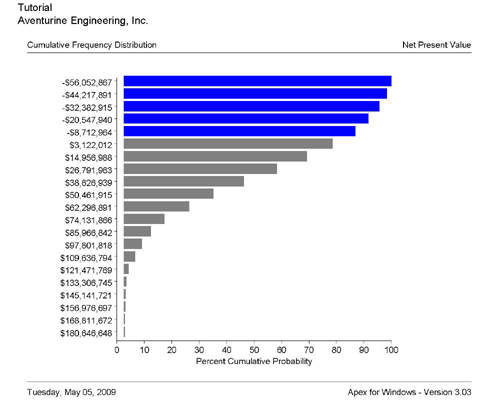

Our Apex economic analysis software for mining projects is the standard of the industry for evaluating the economics of mining projects: a status earned only after years of use by hundreds of mining companies, government agencies, research organizations and mining schools.

Apex reports have appeared in boardrooms, courtrooms and mining offices worldwide. The reason for the software’s success is simple: it consistently, reliably and conveniently provides the answers mining professionals need.

Economic analysis for simple and complex mining projects

Enter simple models into the program in minutes, with the results available in seconds. Complicated models (such as multiple ore types, commodities and smelter or refinery schedules; production costs that vary over time; multiple royalty terms; multiple ore bodies mined simultaneously by differing methods; and equity, loan or joint venture financing) require little added effort.

Cash-flow scheduling for mines

Apex produces a complete cash-flow schedule for your project and then computes the projected net present value, payback period, and internal rate of return on either a before or after-tax basis. You can easily compute the breakeven value for any of the data items you entered, such as ore grade, production rate, stripping ratio, smelting charges or mining costs. Powerful risk and sensitivity modules allow you to examine the economic effects of variations in the data elements.

Contact Details

Email Address

Address

Suite 519,

WA 99201,

Spokane,

Other,

United States of America