KAMAT is an internationally renowned manufacturer of high-pressure technology for use in underground mining environments. The company, which is based in Germany, manufactures pumps and longwall-mining hydraulic systems as well as high pressure pumps and systems for industrial cleaning.

We are proud to supply mine sites in many countries, and have provided pumps for high-performance longwall faces in China, Australia and the US. KAMAT has decades of experience with hydraulic pressure in ranges 350bar to 420bar, and drive power ratings up to 550kW per pump. In other applications, our pumps are operating at pressures up to 3,500bar.

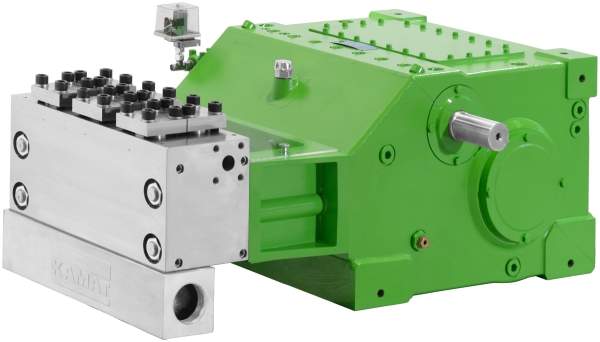

High-pressure plunger pumps for longwall faces

Longwall mining is the most efficient way to extract coal and minerals. Increased demand for efficiency and output has led to ever-increasing longwall face lengths; mining deeper seams results in increasing hydraulic pressures and cylinder diameters; higher production goals need an increased extraction machinery excavation speed, all of which results in a need for powerful, reliable hydraulic stations.

KAMAT has developed plunger pumps and hydraulic stations that meet these demands with relative ease; while much of the mining industry uses pumps with power ratings of 132kW to 350kW, KAMAT supplies pumps from 100kW up to 530kW. We have even provided mining systems with total installed electrical power ratings of over 2,000kW.

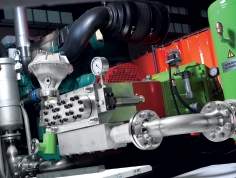

Our pumps can be located in central hydraulic stations in order to supply whole mines, or can be placed in stations near the longwall face to supply it with the required hydraulic fluid.

High delivery-rate pumps for poor water quality

KAMAT pumps are designed to be extremely high-performance, with a high availability and long service life. To achieve this, we ensure all parts in contact with fluid are completely stainless, and make our plungers from solid ceramics.

We recognise the importance of high pump delivery rates, and are able to guarantee rates of up to 895l/min per pump. Up to 640l/min our pumps do not require booster pressure at the inlet. Therefore foam and wear in the whole longwall system are reduced. This fact also provides cost savings. The system requires fewer parts and electrical connectors, meaning fewer components at risk of failure.

KAMAT pumps also do not require drinking-quality water to function well. Our pumps have been designed to cope with poor water quality and particle sizes of up to 250µm filtration, meaning they will work well in environments other pumps will struggle in.

Our pumps also allow a wide range of input speeds and are designed to be very easy to service. Maintenance can be undertaken underground, without dismounting the head, and KAMAT’s practice of using identical parts wherever possible ensures replacements are easy and cheap to acquire.

High-performance pump systems with variable speed drives

KAMAT variable speed drive systems have been used in underground mining facilities since 2002. In industrial applications since 20 years. They are ideal for the job as they always maintain the required nominal flow and pressure but work very gently on pumps, hoses and pipelines.

Our systems are operated simply using a single frequency converter even if several pumps are installed. From this, the input speed can be precisely controlled, with free-selection of the nominal flow rate, from 10% in many cases to 100% full flow.

Our pump systems are developed for foundation frames, caterpillar tracks or suspension in the overhead monorail. Additional systems can be fitted to enable sophisticated monitoring and control. These include:

- Electronic control systems

- Data transmission to central mine control station

- Online emulsion monitoring system

- Fully electronic concentrate dosing system

Hydraulics research and development

KAMAT has garnered an impressive reputation for its sophisticated hydraulics systems. This is due to the company’s focus on customer requirements and detailed industry knowledge.

All the components for our systems are developed by our in-house team to high engineering and quality standards. We see this as essential to producing quality products, and continue to engage in extensive research and development to ensure KAMAT remains at the forefront of hydraulics technology.

Pumps and tools for high-pressure cleaning

KAMAT also supplies a wide range of pumps with an operating pressure up to 3500bar and accessories that are developed to enable high-pressure cleaning. This includes electrically and mechanically controlled tools with precision rotator nozzles, which have been designed specifically for KAMAT systems.

Custom pump systems

We recognise that most sites will require tailored solutions to resolve location-specific issues. To aid this, we are specialised to supply individually adapted complete pump systems and are able to develop solutions for specific fluids and unusual pump system utilisation areas.

KAMAT customer service

All of KAMAT’s technology is manufactured in Witten, Germany, but 80% is used internationally. Each country we service has a dedicated KAMAT representative who will work with you to provide advice, customer service and replacement parts.

If you would like to know more about KAMAT’s range of products and services, please use the contact details below.