Nerospec SK is a global innovator in mine automation technology, dedicated to making mining operations safer, more productive, and more efficient. We specialize in delivering fully integrated, fleetwide automation solutions for mining vehicles, including collision avoidance systems, real-time data monitoring platforms, wireless communication infrastructure, and autonomous vehicle control. Our focus is on providing modular, scalable technologies that enhance safety, operational visibility, equipment reliability, and decision-making across mining operations of all sizes.

Autonomous mining vehicle control – retrofit for safer, more efficient operations

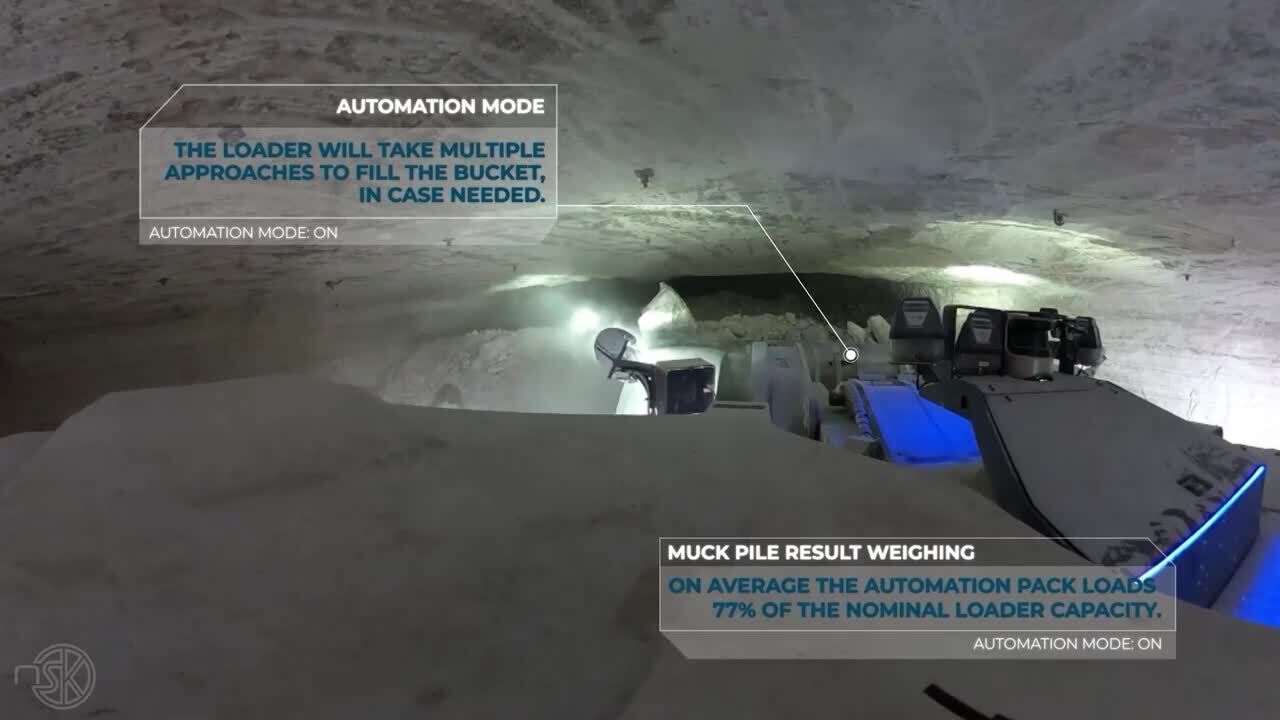

Our fully autonomous retrofit systems, including cyberHUB and Precision Positioning System (PPS), allow mining operators to automate vehicle tasks such as loading, hauling, and dumping—reducing the need for human presence in hazardous areas. With network-free autonomy, our machines can execute operations in remote zones without relying on constant connectivity, improving operational flexibility.

In real-world use cases, Nerospec SK automation has delivered up to 23% increases in productivity, with loading operations achieving over 77% of transport capacity. These technologies support continuous operation even during shift changes or post-blast re-entry periods—critical phases in underground mining.

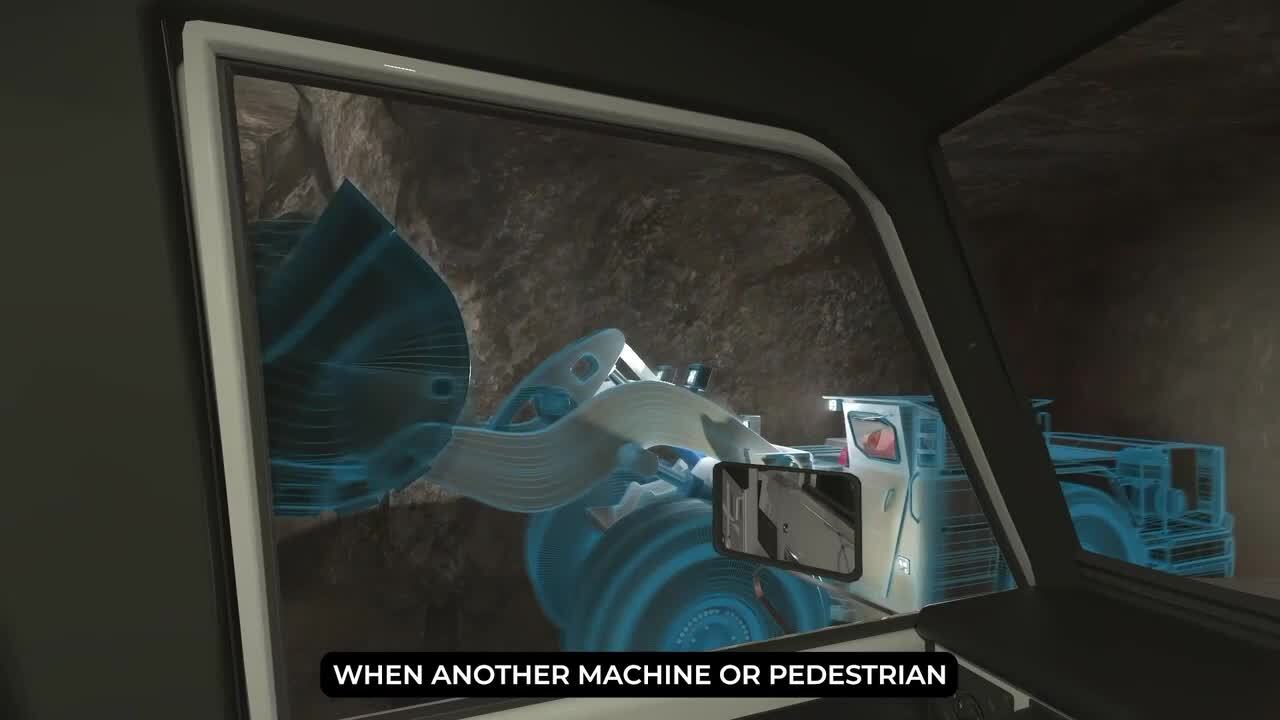

Vehicle Intervention Control (VIC) and level 9 safety compliance

Vehicle Intervention Control (VIC) enables Level 9 Collision Avoidance, ensuring automatic vehicle behavior adjustment when unsafe proximity is detected. This helps eliminate operator error in high-risk scenarios, aligning with EMESRT’s Design Philosophies for mobile equipment safety.

By integrating fleetwide Vehicle Intervention Control (VIC), our clients report a drastic reduction in high-potential incidents. In fact, preventing just one equipment collision can save an estimated USD $1 million in operational costs and lives. Nerospec SK’s CAS contributes to a “Zero Incident Future”—saving lives through proactive, real-time collision mitigation.

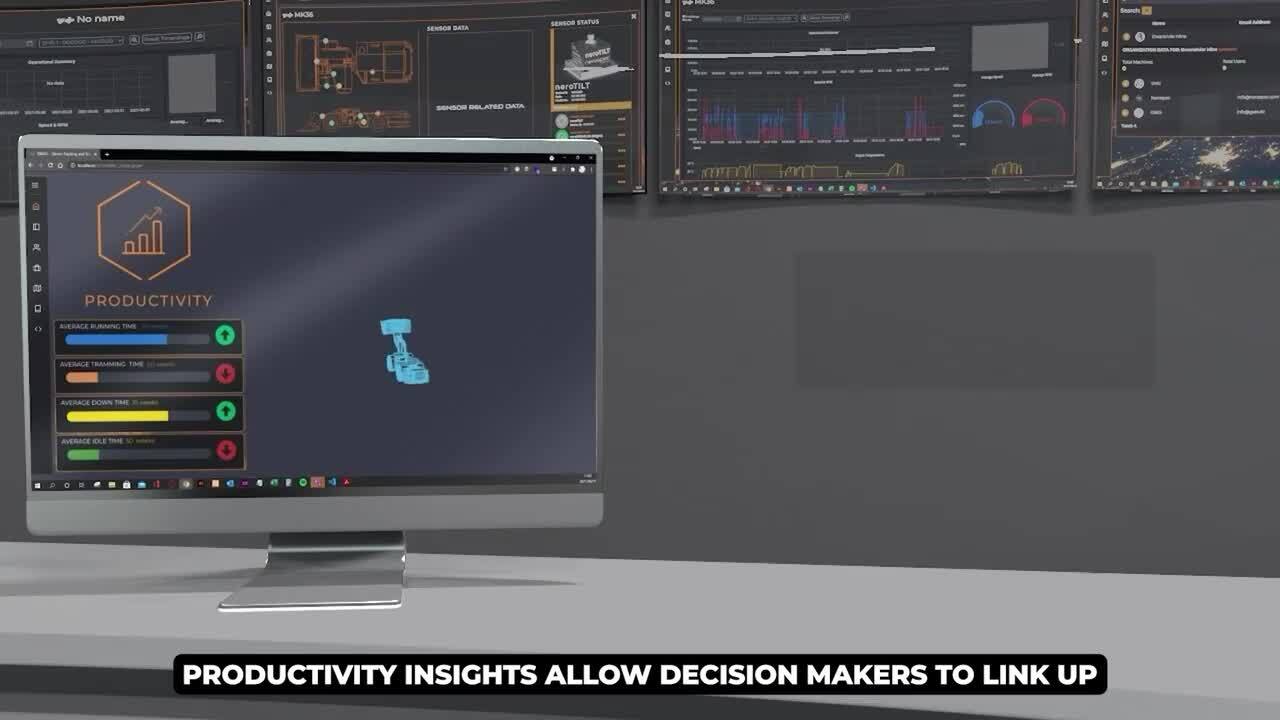

Fleet data monitoring for operational intelligence

Our Fleet Data Monitoring (FDM) platform connects mine machines to provide real-time insights, supporting smarter maintenance and performance strategies. Through embedded sensors and Short Interval Monitoring And Control (SIMAC), we enable condition-based maintenance that reduces unplanned downtime and extends asset lifespans.

The system also boosts Overall Equipment Effectiveness (OEE) by over 20%, providing operational benchmarks across cycle times, fuel consumption, and maintenance KPIs. Fleet-wide connectivity ensures the seamless flow of production data, helping operators identify performance gaps and act fast.

neroMAN wireless communication: the nerve center of your mine

Our proprietary neroMAN (Mine Area Network) ensures robust, real-time wireless underground communication. This infrastructure supports mobile access to diagnostics, machine control, hazard alerts, and centralized reporting—transforming mines into digitally connected environments.

With neroMAN, data from equipment and personnel flows instantly across the operation. The system supports immediate hazard alerts and remote diagnostics, enhancing both productivity and miner safety. It’s the backbone for seamless automation and effective fleet monitoring across distributed mining zones.

Total integration: end-to-end, OEM-agnostic mining technology

Nerospec SK offers a modular, OEM-agnostic ecosystem for total mining automation. Whether integrating with new equipment or retrofitting older assets, our system includes:

• Autonomy & Controller Family – Automate repetitive tasks with minimal human intervention

• Vehicle Intervention & PDS Integration – Achieve EMESRT Level 9 compliance with real-time safety controls

• Fleet Data Monitoring – Unlock insights into performance and maintenance via connected sensors

• Traffic Management & Positioning UG – Track assets and personnel with high-accuracy positioning tools

• Wireless Communication (UG LTE, Wi-Fi Booster UG, Leaky Feeder) – Keep all systems and staff in sync, no matter how deep underground

These systems are designed, manufactured, and maintained in-house, giving clients full support from scoping to deployment and performance optimization.

Global reach, local expertise

With more than 300 employees worldwide, Nerospec SK is truly a global company. Our automation competence center is based in Velbert, Germany, while our product development and manufacturing teams operate out of Johannesburg, South Africa. This international structure enables us to deliver global innovation with local insight and agility.

We have successfully deployed our technologies in some of the world’s most complex and demanding mining environments, and we are continuously expanding our reach in collaboration with mining companies, OEMs, and technology partners.