Transmission VOLVO PT SERIES

For over 30 years, Centranz has maintained a reputation for excellence in remanufacturing Volvo PT series transmissions for Volvo articulated haulers.

Centranz remanufactures hydraulic transmissions for heavy equipment in the mining and quarry industry.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

Centranz remanufactures hydraulic transmissions for heavy equipment in the mining and quarry industry. With a large inventory of Allison, Volvo and ZF cores for exchange, Centranz can provide quick turnaround service for Allison, Volvo, Euclid, Hitachi, Terex (Rokbak), CAT, Hyundai, Kawasaki, Komatsu, and Liebherr machinery.

If a core is not available on the shelf, Centranz has a full-service machine shop on-site (Centranz Parts and Manufacturing) to supply newly-manufactured or reclaimed parts so our service technicians can remanufacture the original transmission quickly and efficiently.

Centranz remanufactured transmissions receive new plates, bearings, gaskets, seals, thrust washers, and valve body springs. New electronic solenoids, switches, sensors, and senders are also installed. All remanufactured transmissions are dyno-tested before they leave our shop, undergoing a rigorous 5-step evaluation to ensure proper functionality and allowing Centranz to offer a warranty that is second to none in the industry.

CPM distributes high-quality replacement parts for Volvo, ZF, CAT and Allison Equipment. We are a stocking distributor for Swedish Lorry Parts (SLP), Trazione Gears, Friction Marketing Company (FMC) which offers high-quality clutch plates, and a European manufacturer of spiral bevel gears for differentials for Volvo construction equipment.

CPM manufactures high-quality replacement parts for Volvo, Allison, CAT and ZF equipment. We sell to the consumers as well as OEMs such as Terex.

Our reverse engineering process begins with a metallurgical analysis to ensure the materials are equivalent or superior to the OEM material selection. We then utilize calibrated conventional gauges and calibrated coordinate measuring machines, with all turning and milling done on late model CNC turning and milling machines. All heat treating is performed by worldwide-respected companies and parts are tested for fit and function prior to shipping.

Drop boxes remanufactured by Centranz receive all new bearings, gaskets and seals, while new electronic solenoids, switches, sensors and senders are also installed. Centranz supplies its customers with turnkey installations, including the latest hard part updates, ensuring all switches and sensors are adjusted prior to leaving the shop.

Centranz remanufactured differentials receive all new bearings, gaskets and seals. New ring and pinion sets and new nest kits are installed as needed from our large inventory. Centranz has the ability to repair the main housing in-house using CNC machine tool technology for efficiency and reliability. All bearing clearances, loads and gear backlash settings are performed per factory specifications.

Centranz understands the enormous cost in time and money when a machine becomes immobilized, often obstructing operations. To address this, Centranz created TestBox and created a subsidiary company, Test Equipment Manufacturing Company (TEM-CO), to manufacture and market TestBox.TestBox can directly diagnose transmission problems through measurement of sensors and solenoids displaying the results on a simple-to-read display screen. The system can verify whether or not the transmission is working – narrowing down troubleshooting of an immobilized vehicle.

If the problem is due to the transmission control electronics, TestBox can override them and in a critical situation, allow the operator to move the machine to a different location for further diagnosis and repair.

With over 50 years of experience, Centranz is an expert in the remanufacture of transmissions for off-highway equipment. Our fully-equipped machine shop and extensive inventory of parts gives our customers reliable products with a quick turnaround time at competitive prices and the industry’s best warranty.

Centranz offers pickup and delivery to most regions in the US. Our parts distributorship permits us to provide customers with high-quality replacement parts for Volvo, ZF, CAT and Allison in a convenient manner at a cost-effective price. Centranz is happy to provide you with additional information about our products and services so you can see for yourself how we can save you time and money.

For over 30 years, Centranz has maintained a reputation for excellence in remanufacturing Volvo PT series transmissions for Volvo articulated haulers.

Centranz is a leading remanufacturer of ZF transmissions that fit Terex (Rokbak), Moxy, Bell, Doosan, Liebherr and other articulated trucks.

Centranz is a leading remanufacturer of ZF transmissions that fit John Deere, CASE, JCB, Doosan, Bell and other wheel loaders.

Featuring upgraded engineering, all drop boxes include an industry leading two-year, unlimited-hour warranty.

As the definitive source for Volvo differentials, we stock replacement parts for every differential we sell.

Our unique remanufacturing process, complemented by a full-service machine shop, ensures maximum durability in the field.

Centranz is a global leader in remanufacturing Allison transmissions with applications in mining, construction and oil field services.

Centranz specializes in remanufacturing transmissions for Caterpillar (CAT) articulated trucks, including models 725, 730, 735, 740 and 745.

Centranz is a global leader in remanufacturing transmissions and drivetrain components for heavy equipment used in the mining industry, including rigid frame trucks, articulated dump trucks and wheel loaders.

Featuring full-service machining capabilities, Centranz manufactures hundreds of unique parts in house and has specialized relationships with companies worldwide that produce OEM-quality parts at discounted rates.

TestBox can directly diagnose transmission problems for on- and off-highway vehicles – and verify whether a transmission is performing properly – by measuring sensors and solenoids, displaying the results on an easy-to-read screen.

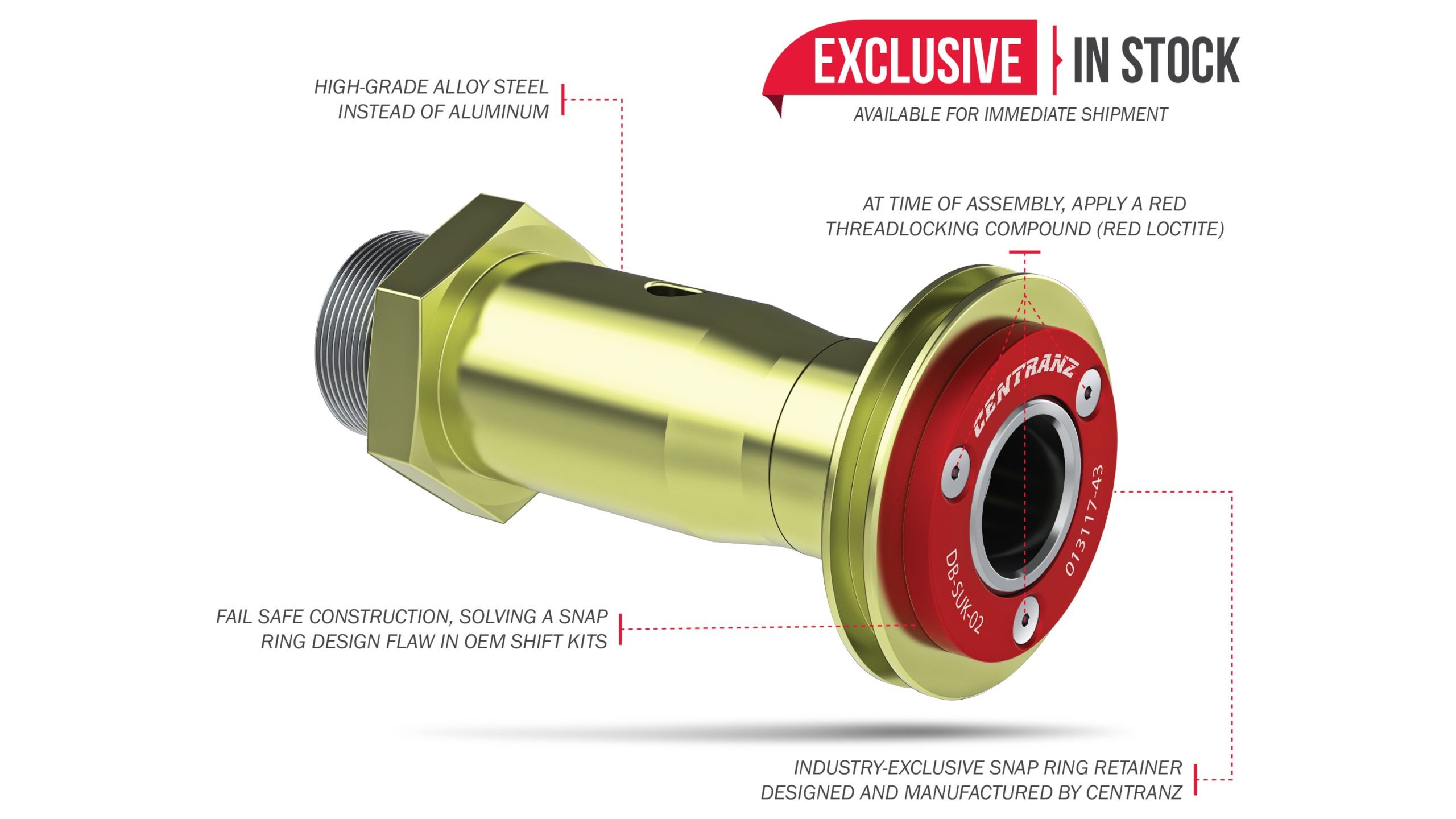

The Volvo Drop Box Differential Lock Shift Upgrade Kit (DB-SUK) features a fail-safe construction, solving a snap ring design flaw in OEM shift kits. It's made from high-grade alloy steel instead of aluminum and includes a snap ring retainer designed and manufactured by Centranz.

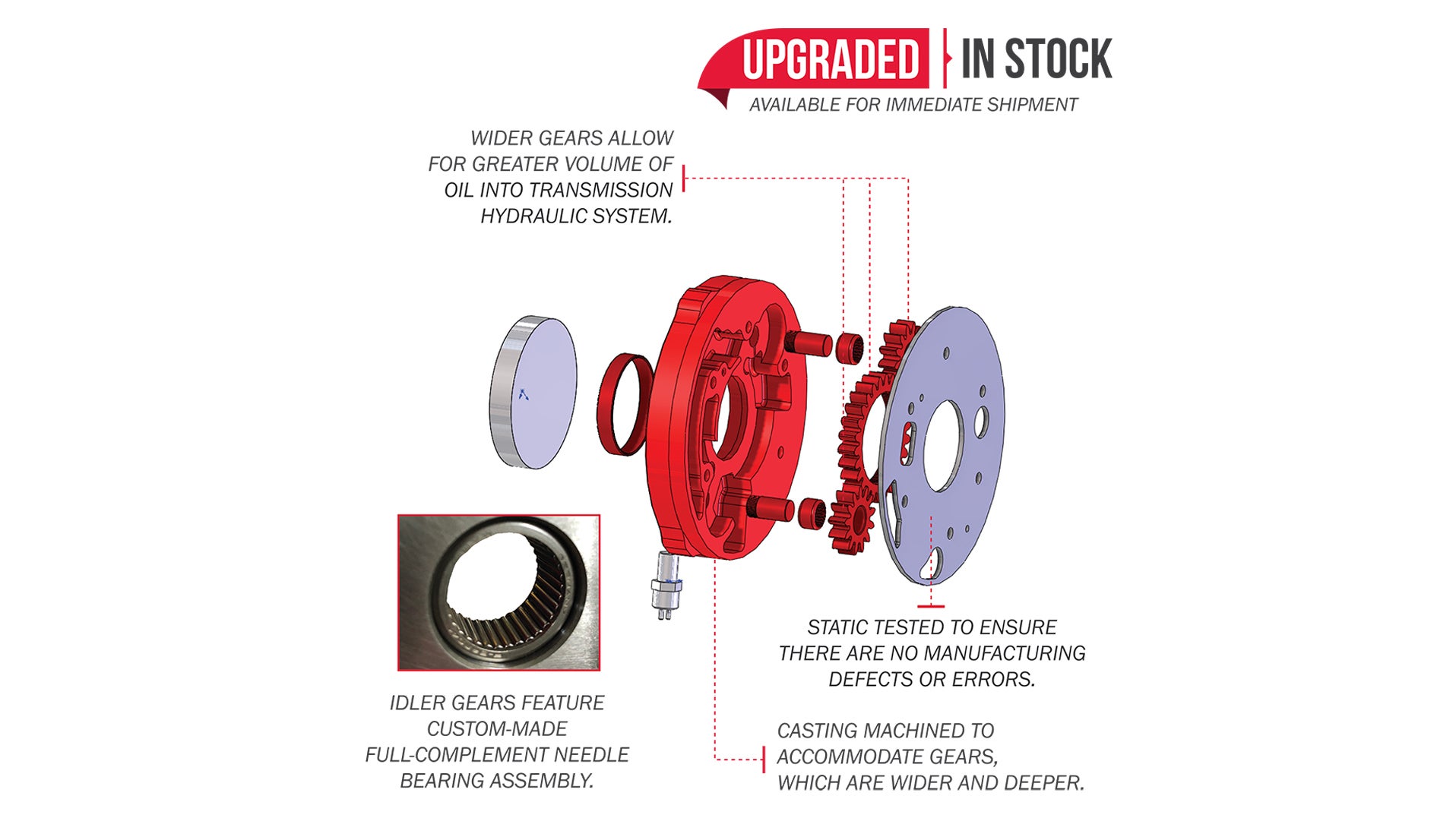

Centranz's pumps are uniquely engineered with wider gears to allow for a greater volume of oil to enter the transmission hydraulic system.

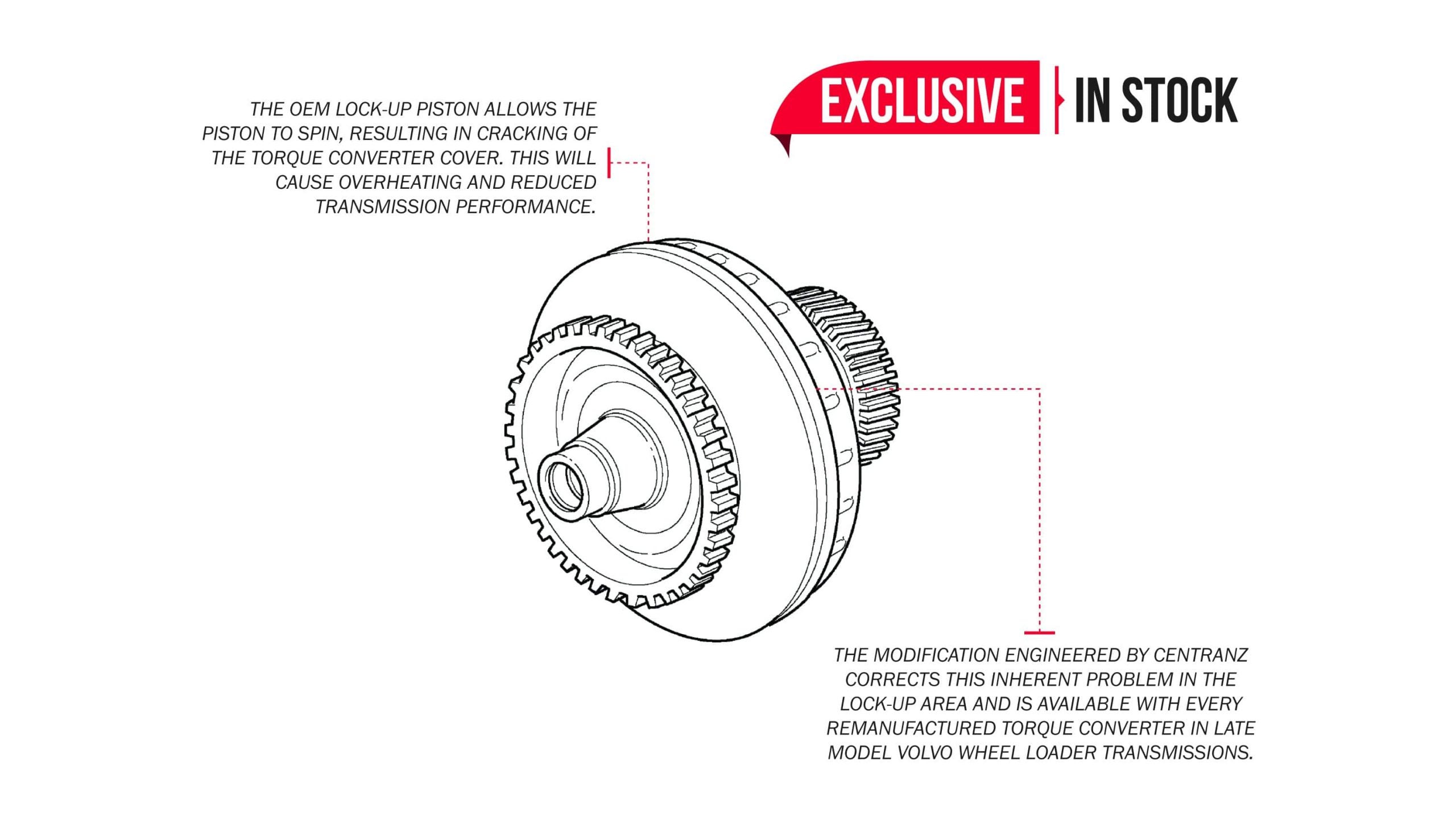

The OEM lock-up piston allows the piston to spin, resulting in cracking of the torque converter cover. This will cause overheating and reduced transmission performance. The modification engineered by Centranz corrects this inherent problem.

Original flywheels are made of four pieces welded together. These welded areas ultimately fail, resulting in a leaking torque converter. Centranz's premium flywheels are made from a solid billet that’s not welded or fabricated, preventing oil from leaking.

No one likes downtime. At Centranz we're here to help, any way we can. When you call us a real person answers, not an automated system. We offer troubleshooting advice free of charge.

Since its founding in 1970, Centranz has undergone a lot of changes. Its name has changed; its location has changed; its service offerings have changed. But certain qualities remain the same.

The Centranz team showcased our latest products, many of which feature upgraded engineering and offer one-of-a-kind solutions to OEM design flaws.

DB-SUK (Drop Box features a fail-safe construction, solving a snap ring design flaw in OEM shift kits. It's made from high-grade alloy steel instead of aluminum.

For more than 50 years, Centranz has set the industry standard for quality. We completely disassemble and clean every remanufactured or repaired transmission to properly identify the root cause of a failure and potential future failures.

Our premium flywheels are made from a solid forging that’s not welded or fabricated, preventing oil from leaking.

Developed by Centranz, TestBox can directly diagnose transmission problems for on- and off-highway vehicles.

For 30 years, Centranz has maintained a reputation for excellence in remanufacturing Volvo PT series transmissions for Volvo articulated haulers.