LA STEPHANOISE

Mining Equipment for Product Extraction and Bulk Material Handling

Subscribed

You have successfully submitted your enquiry. Someone from our company will respond ASAP

About Us

LA STEPHANOISE is known worldwide mainly in the underground mining industry for the manufacture and supply of material handling equipment.

We develop armoured chain conveyors, belt conveyors, longwall material and breakers for underground mining for all solid bulk products such as coal, limestone, clinker, cement. We also supply equipment in quarries, cement plants, steelworks and more.

With more than one century of experience, innovation and manufacturing, and because of its proximity to Saint-Etienne’s coal mines and to the oldest French coalfields, LA STEPHANOISE has actively developed equipment intended for underground operations worldwide.

Underground belt conveyors

LA STEPHANOISE’s belt conveyors are specially designed and adapted for an underground environment with potential gas presence. They are generally very compact and robust.

There are three main types of belt conveyor:

- Inclined conveyors of access tunnels where reliability is essential for good productivity of the mine. In fact, these transporters are used to transport the coal outside. They generally have a high power

- Interchange conveyors between galleries. They are very compact and most often suspended

- Telescopic conveyors installed near the faces, generally upstream of a stage loader. They have a band storage allowing gradual reduction as the face is exploited

Armoured face conveyors

Our armoured face conveyors are suitable for blasting sites and adjacent galleries due to their capacity for continuous transport of raw ores.

The robustness and efficiency of the armoured conveyors made by LA STEPHANOISE make them an essential asset on site.

In fact, they are designed to guarantee a long service life with a low rate of failure in environments with high levels of constraints and requirements.

They are also used with Stage Loaders, which are placed in primary galleries and receive the products from the armoured face conveyors and discharge them to the belt conveyors or scraper conveyors located upstream. They are often equipped with breakers and must be mobile in order to follow the work progress.

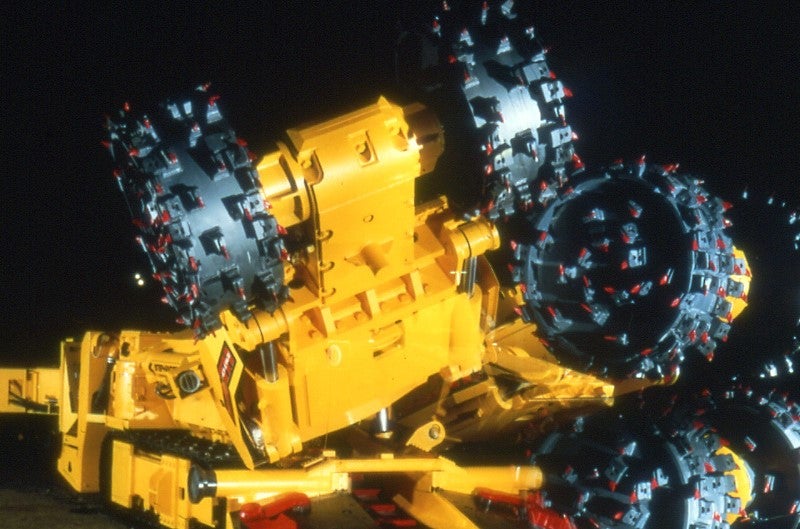

Feeder breakers

LA STEPHANOISE’s feeder breakers are widely used in mines and quarries.

They are designed to perform three functions, including:

- To enable ore from the upstream shuttle to be poured at maximum speed and stored temporarily due to their large capacity

- To spread the load thus produced in order to supply the downstream conveyor belts with a regular flow

- To break the blocks and reduce them to a size compatible with the width of the belts

The operation and efficiency of the downstream handling installation are greatly improved, providing:

- A compact installation

- Possibility of using a narrower belt

- Longer belt and roller lifetime

- A reduction in the power and size of the secondary breakers

It is possible to install two breakers in series on the same extractor conveyor for processing very large blocks, the first performing pre-crushing and the second producing the required grain size.

Apron feeders for bulk material handling applications

LA STEPHANOISE’s apron feeders are mainly used for handling dense and heterogeneous bulk materials.

They are able to withstand impact from heavy blocks falling from great heights without damage and to handle variations in grain size, they are installed:

- Under an open hopper, when they are used as feeders

- Under a closed hopper or a primary crushing station when they are used for extracting the product

Generally speaking, this equipment is notable for its ruggedness and high level of reliability, requiring very little maintenance.

Longwall shearers

LA STEPHANOISE’s longwall shearers are used in underground works to extract excavation materials or the ore in mine galleries and rock faces.

The ore exploitation in mines is mainly achieved through two methods, namely longwall or room and pillar mining.

The drawdown extraction method is the complete exploitation of coal panels with backfilling or a caving roof. In this instance, the longwall shearer is installed onto an armoured underground chain conveyor.

The room and pillar extraction method is a grid extraction in which pillars are retained to support the roof and upper ground. In this case, the heading and loading machine is mobile and self-propelled.

Gearboxes for open-pit and underground mines

LA STEPHANOISE offers a wide range of gearboxes that are compatible with the majority of open-pit and underground mining equipment.

Manufactured to offer a long service life, these gearboxes are extremely tough and designed for adverse environments.

Contact Details

Website

Address

76 D rue de la Talaudière,

42000 Saint Etienne,

France