IVAC develops heavy-duty industrial vacuum systems for adverse material transfer applications in the global mining and offshore industries.

We manufacture and supply industrial vacuums that offer safe, efficient solutions to pump sand, gravel, slurries, slimes, and virtually any media that can fit into the intake port.

Reliable, maintenance-free industrial vacuum systems for the mining sector

IVAC Industrial Vacuum Systems are an all-purpose solution to almost any industrial clean-up application.

Our systems can be customised to meet particular specifications required by the application requirements. Stainless-steel tanks are used for hazardous and / or caustic materials, pneumatic control panels for high-risk explosive areas or even additional safety features to comply with differing countries’ safety standards. IVAC equipment can pump up from depths and deliver products further than is possible with conventional pumping equipment.

In addition, our powerful venturi eductor pump patented system is built to last while moving high volumes of aggregate, slurries, proppant, sands or any other difficult-to-pump materials.

Mobile vacuum systems

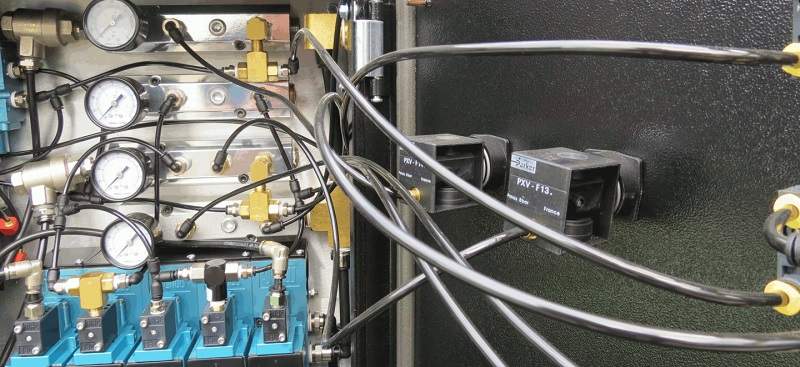

Our versatile flagship PV500 and PV250 systems run on compressed air and have only three moving parts (knife gates).

By limiting interaction between abrasive media and the working mechanisms, our portable and compact machines are able to run trouble-free for years.

Through utilising industrial hoses with our vacuum systems, we are able to pump from almost any location with a completely controlled discharge, pumped into holding tanks, totes, bags or even piped offsite.

Applications for industrial vacuum systems

Our vacuum solutions are used in a wide range of industries and applications, including:

- Underground mining: pumping sand in drifts (tunnels), cleaning under conveyors, sumps and ditches, shaft bottom clean-up and pumping sludges

- Silos: high-volume sand, cement and grain transfer

- Railcar-product recovery, pumping material for loading and unloading processes

- Smelters and manufacturing plants: pump nickel concentrate, product recovery, transfer iron bearings

- Land reclamation: pumping sand accumulations from residential areas, pumping sand, sludge and other contaminants from sensitive environments

- Foundries: pump sand-blast media, material recovery, storage tank clean out

- Water treatment facilities: removal of sewerage grit, wastewater for system cleaning and optimisation

- Ships: sand ballast removal, holding tank muck out, large volume material transfer

Vacuum system accessories

We manufacture pick-up nozzles, loading trays, hoppers and many other specialised material transfer options to ensure the correct accessories for each specific pumping application.

Our research and development team is constantly working to upgrade and improve our products, as well as creating custom equipment, tailored to your exact needs and specifications.

Lift assistants for vertical pumping applications

The Vertical Lift Assistant (VLA) accessory increases suction depth when cleaning out areas far below the vacuum unit.

It is useful when dealing with wet materials and sludges when the lift is greater than 25ft.

The VLA provides a ‘burst’ of air into the suction line to assist the material to move toward the vacuum unit by filling the suction line and then pumping material to the vacuum unit by injecting compressed air.

This is done automatically by the VLA timer and valves located on the PV Vacuum unit.

Customer satisfaction and instructional support

Our service personnel are here to help clients with the right advice, online or by phone with prompt, informed service when needed.

We guarantee this by having actual technicians available, who build and work with the units on a daily basis.

We also produce a wide variety of operator manuals, informational brochures and instructional videos.