Powderful Solutions is a leading producer of unique proprietary submicron multi-layered WS2, MoS2 and hBN particles, disperesed in extreme pressure additives/components to enhance tribological and heat transfer properties in various oils, greases, coolants and coating formulations.

Powderful Solutions has accumulated experience, knowledge and unique know-how, production and R&D capabilities, tested and proven case studies and, above all, successful commercial activity with a solid customer base implemented in mass volumes.

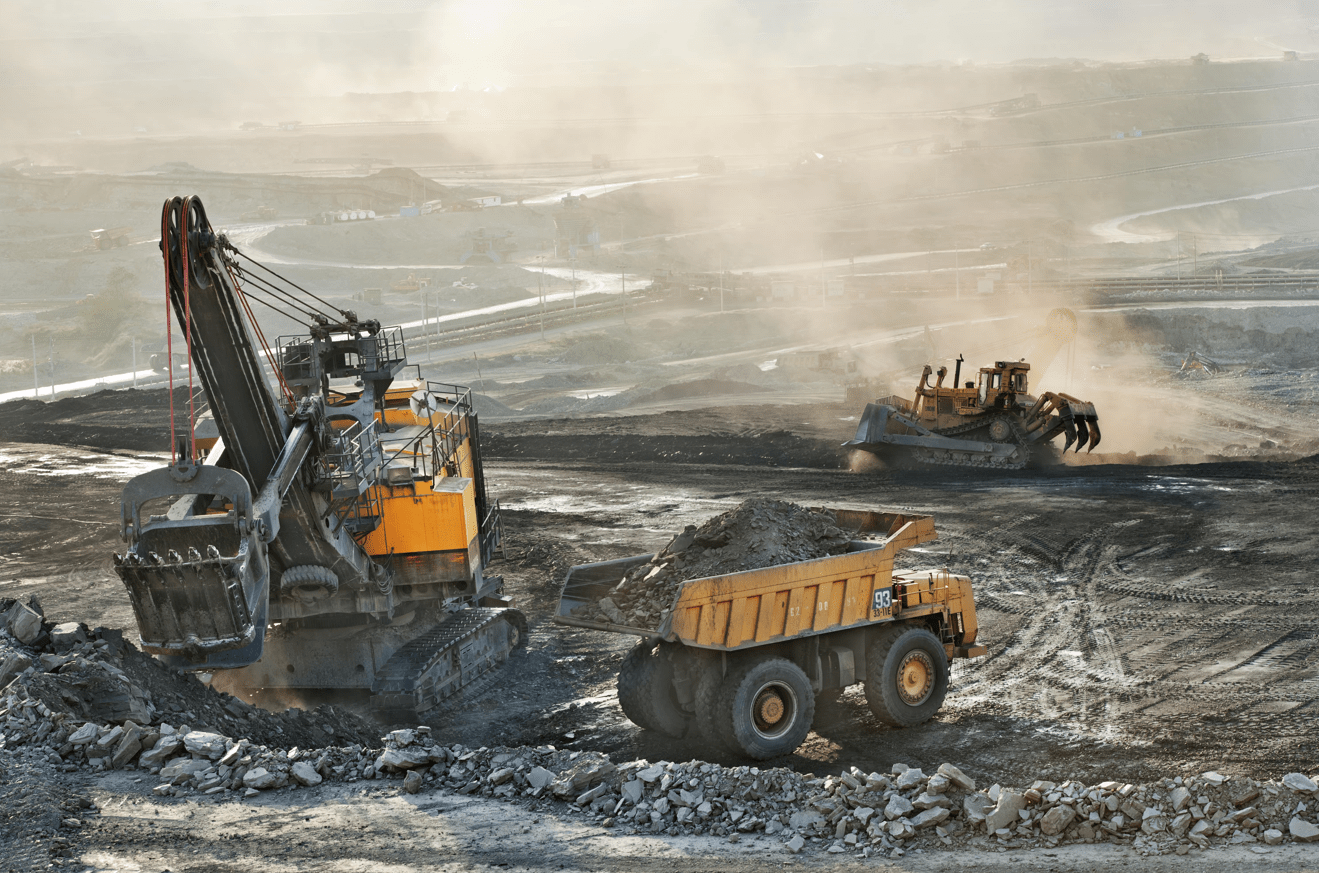

Innovative antiwear lubrication solutions for mining operations

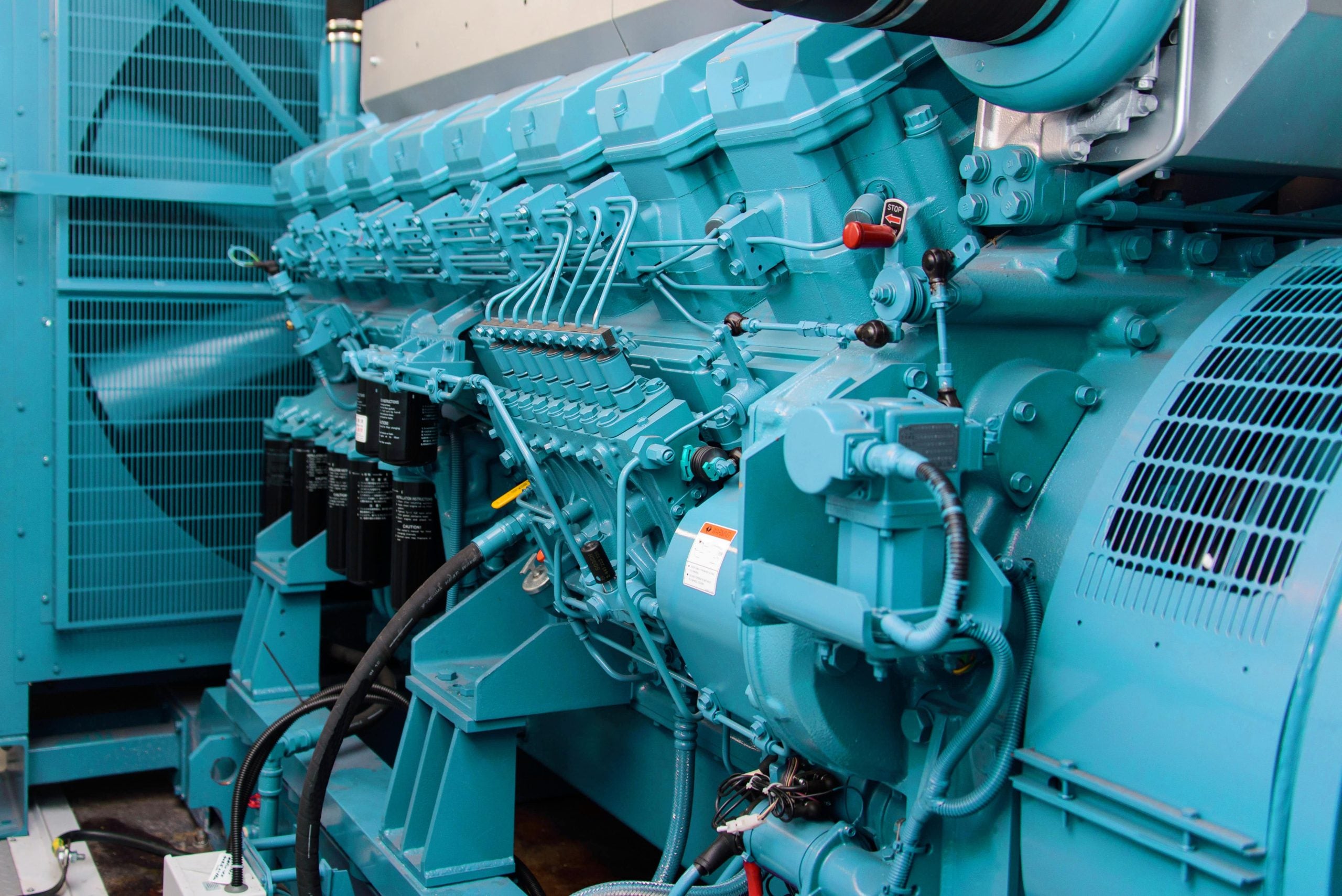

In the realm of heavy-duty and mining equipment, the efficiency and longevity of machinery are paramount for operational success. One critical aspect that significantly influences the performance and durability of such equipment is the lubricants used.

Innovative antiwear and antifriction lubricants play a crucial role in reducing friction, wear, and heat generation, thereby enhancing the overall efficiency and lifespan of heavy-duty and mining equipment.

Heavy-duty and mining equipment operate under extreme conditions, including high loads, high temperatures, and harsh environments. In such demanding settings, proper lubrication is essential to minimise wear, reduce friction, dissipate heat, and protect critical components from damage.

Without adequate lubrication, equipment is prone to premature failure, increased maintenance costs, and downtime, all of which can have significant economic repercussions for mining operations.

High-performance lubricants for superior performance

High-performance lubricants designed for heavy-duty and mining equipment exhibit several key characteristics that differentiate them from conventional lubricants. These characteristics include superior antiwear properties, excellent thermal stability, high load-carrying capacity, corrosion resistance, and compatibility with various materials commonly found in heavy machinery.

Recent advancements in lubricant technology have led to the development of innovative formulations tailored specifically for heavy-duty and mining applications. Nanotechnology, for instance, has enabled the creation of lubricants with nanoparticles that provide enhanced lubricity, reduced friction, and improved wear protection.

Additionally, synthetic base oils and advanced additive packages have been engineered to deliver superior performance under extreme conditions, prolonging equipment life and reducing maintenance requirements.

Solutions to reduce corrosion and boost equipment longevity

Powderful Solution lubricants have achieved superior performance by using a highly innovative composite submicron solids of various geometries, such as Hexagonal Boron Nitride, (hBN), Tungsten Disulfide (WS2) and Molybdenum Disulfide (MoS2).

The unique composite solids create very lubricious and extremely strong layers on a metal surface enabling reduction of friction by up to 40%. Reduced friction has a direct impact on lowering operating temperatures and reduction of metal wear.

These properties translate into tangible benefits for the operators of mining equipment:

● Significantly improved mechanical performance

● Extended machine life

● Less equipment breakdown reducing overall equipment down time

● Lower service requirements resulting in longer service cycles

● More efficient energy consumption

The adoption of high-performance antiwear and antifriction lubricants in heavy-duty and mining equipment offers a multitude of benefits. These include extended equipment life, reduced maintenance costs, increased operational efficiency, enhanced energy efficiency, and minimised environmental impact. By using lubricants that are specifically formulated for the rigors of heavy-duty and mining operations, companies can optimise equipment performance and maximise productivity.

Numerous case studies and success stories highlight the tangible benefits of using high-performance lubricants in heavy-duty and mining equipment. Companies that have made the switch to innovative lubricant solutions have reported significant improvements in equipment reliability, reduced downtime, and substantial cost savings. These real-world examples serve as compelling evidence of the positive impact that advanced lubricants can have on operational efficiency and profitability.

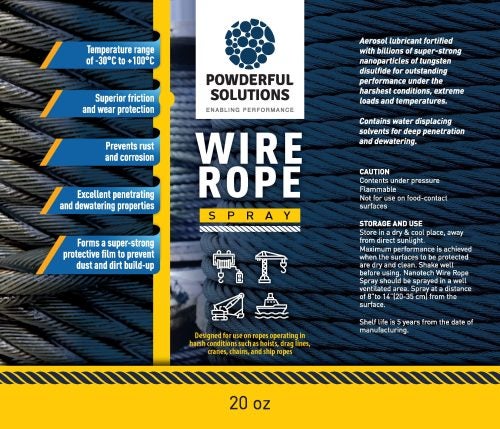

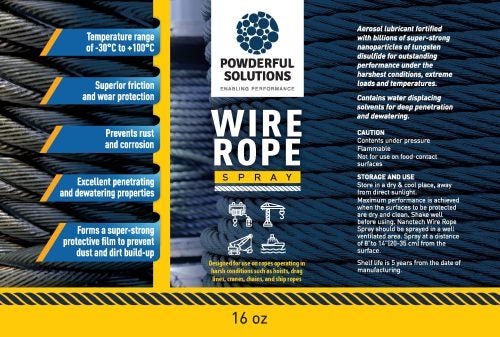

Powderful Solutions has a diversified product line, including:

- Engine Oil Top-Up Additives

- Gear/Industrial Oil Top-Up Additives and formulation Packages

- Grease Additive Packages

Technology alone doesn’t solve problems. Powderful Solutions has many local partners to offer a full logistical tailor-maid solution, uniquely designed for your needs. In the mining industry, our team can provide mining operators a competitive adge benefiting from decades of experience in high performance lubricants. We can design a full line of high performance lubricants based on your requirements.

All types of greases and oils – NLGI Grade /Base Oil/ Thickener / Application /Specification etc.

Our offer will outperform current supply while being price competitive.

In conclusion, high-performance innovative antiwear and antifriction lubricants play a vital role in optimizing the performance and longevity of heavy-duty and mining equipment. By leveraging the latest advancements in lubricant technology, companies can enhance equipment reliability, reduce maintenance costs, and improve overall operational efficiency.