Organic catalysts improve environmental waste treatment in a number of critical maintenance and processing areas.

Organic catalysts improve environmental waste treatment in a number of critical maintenance and processing areas.

Key attributes that make organic catalysts uniquely attractive are its ability to elevate the level of dissolved oxygen (DO) in solution, regardless of aeration technique; ability to solubilise the molecular structure of organic wastes, including the insoluble fats, oils, and grease (FOGs) components; eliminating chronic and dangerous volatile organic compounds (VOCs), such as ammonia and H2S gases; and the ability to enhance biological nitrogen removal (BNR) systems.

Sewers: Maintaining aerobic environments within collection systems is essential to avoid chronic service problems and dangerous conditions due to hazardous gases, which are also the source of most public complaints. Eliminating slime layers and FOG clogging are excellent maintenance applications for organic catalysts. They can also be used to increase dissolved oxygen levels within gravity and forced mains, as well as other aerobically compromised parts of the system.

Aeration Systems: Organic catalysts has been shown to make a substantial improvement in aeration systems through raising dissolved oxygen levels, increasing gas transfer rates, and improving bioprocesses. Improving aeration system performance can lower energy requirements (up to 30%), along with acting as a method for maintaining higher dissolved oxygen (DO) levels during heavier loading periods, which provides operators with a means to better manage optimum microbiological activities.

Sludge Processing: Processing of bio-solids can be substantially improved with addition of organic catalysts. Sludge volumes have been significantly reduced (up to 40%) while methane production quantities were maintained in full-scale applications. Subsequent treatment and handling of bio-solids can be improved due to reduction in odour and better bio-processing of the bacterial components.

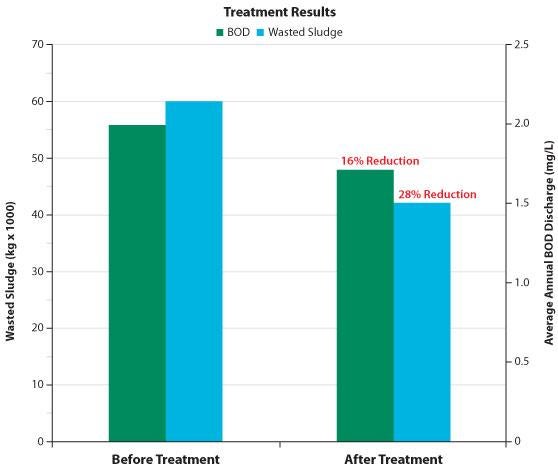

The graph is from a case study at Fontana Walworth WWTP, USA:

- 3.8 MLD, residential/industrial wastewater

- 52-week trial results

- 2ppm bio-catalyst

- 28% reduction in wasted sludge

- 16% reduction in BOD (34% during peaks)

- Odour elimination