Clear Edge Filtration

Screen and Filter, Process Belts and Screen Print

Subscribed

You have successfully submitted your enquiry. Someone from our company will respond ASAP

About Us

Clear Edge Filtration is a leading global company supplying industrial filtration products and filter media to companies engaged in filtering liquids, from solids, dewatering, collecting and filtering dust, air filtration, filtering and purifying hot gases and other niche industrial process applications.

Clear Edge Filtration wet and dry filter media are used on drum, disc, horizontal belt and pan filters in the mineral processing industries. Clear Edge Filtration excels at taking ownership of your mining process challenges and presenting innovative solutions.

Companies on every continent rely on our global infrastructure, which provides a vast geographical reach, plus the best local technical service the world has to offer. Our goal is 100% total customer satisfaction.

Technical filtration services and laboratory analysis

Clear Edge Filtration is committed to innovation and modern filtration technology. World-class laboratories and research facilities allow our customers to experience the most advanced and application specific filtration solutions customized for individual requirements.

Scientists and application engineers at Clear Edge Filtration remain focused on process improvements, separating solids from liquids and particles from gasses more efficiently. Close cooperation with top scientific universities, research institutions and original equipment manufacturers ensures leading-edge solutions for our customers.

Clear Edge Filtration has invested in a new state-of-the-art media development laboratory, based at its European HQ in Germany. As well as developing new products and technologies for the industrial filtration process market, the lab has range of high-tech equipment and qualified scientists capable of offering technical service to customers.

The lab consists of analytical, chemical, physical testing, library and storage areas and employees a multi-disciplinary team consisting of chemists, textile and mechanical engineers, material scientists and chemical engineers.

In summary, the lab is able to offer a range of services to its global customer base including the following:

Basic testing service (level 1)

- Material characteristics of natural, synthetic (polymeric), ceramic or metallic structures, such as textile yarn characteristics including diameter, density (linear), yarn type (mono, multi) and thread count

- Material thickness, weight and permeability

- Mechanical testing, strength, elongation including low load elongation

- Basis microscopy image (front, backside and cross-section)

In most cases basic testing can be performed in a few days and a report can be issued. This service is free to customers of Clear Edge Filtration.

Advanced testing capability (level 2)

- SEM characterization including particle sizing where applicable

- Pressure and vacuum filter testing

- Tests on the use of filter aids, flocculants and polymers

- Pore size distribution (PSD) of materials

- Challenge tests (%) and retention efficiency (3um-1000um)

- Liquid permeability and hydrolysis testing

- Laser particle sizing (0.04hm-2000um)

- Chemical and thermal analysis of materials (DSC)

- Advanced mechanical testing including strength / elongation / creep at temperature and abrasion resistance

- Intellectual property (IP) investigations

- Advice on filter media cake release and cleaning methods

Clear Edge Filtration products

Staggering demand on natural resources and precious metals has caused the mining industry to increase production and decrease ecological footprints. Clear Edge Filtration products help to minimize downtime, decrease replacement times and reduce the total cost of ownership.

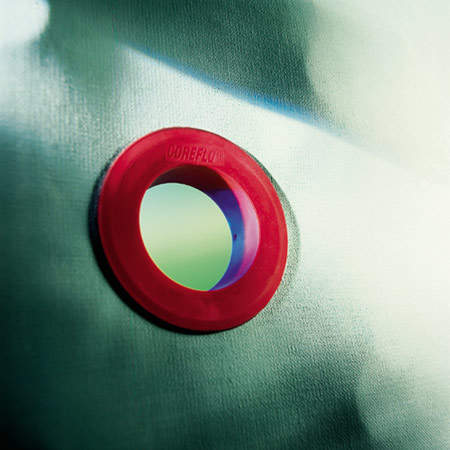

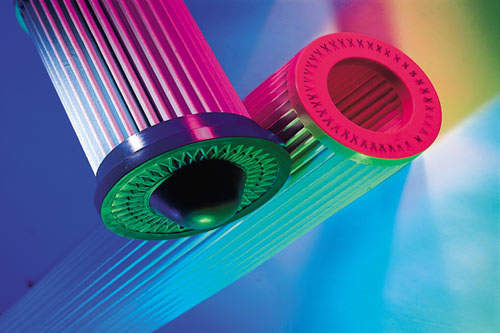

Clear Edge Filtration mining products include candle filter bags, drum pan disc covers, dust bags, filter press fabrics, horizontal vacuum belts, kelly bags, pressure leaf covers, screening fabrics, spiral belts, tower press belts, woven filter belts, linear screens and ceramic elements.

Clear Edge Filtration global locations

Clear Edge Filtration is proud to service numerous mining industries, including alumina, gold, coal, nickel, lead, zinc, PGM and iron. Clear Edge Filtration locations span across the world’s mineral-rich regions including Australia, North America, South America, Europe, Russia, China and South Africa.

Contact Details

Website

Email Address

Address

Suite 570,

Tulsa,

OK 74104,

Other,

United States of America