Optech is a world leader in the development, manufacture and support of advanced lidar and camera survey instruments. With operations and staff worldwide, Optech offers both stand-alone and fully-integrated lidar and camera solutions in mine cavity monitoring, terrestrial laser scanning, mobile mapping, airborne terrestrial mapping and bathymetry, and industrial process control, as well as space-proven sensors.

Cavity monitoring systems for mines

The Optech Cavity Monitoring System (CMS) is an autoscanning laser that collects thousands of accurately located points to determine a cavity’s size, orientation and volume, and to create detailed engineering drawings.

The Optech CMS is an ideal scanning solution for dangerous and inaccessible cavities. Mine safety is the key behind its design and operation, safeguarding users by extending the scanning head deep into hazardous or inaccessible areas while mining personnel stand clear. The 3D spatial data collected by the CMS enables mine operators to gain accurate insight to the mine’s structure.

Universally adopted data formats ensure that CMS data can be used in any software workflow. The system is easy to transport and set up and is fully programmable, allowing the user to define scan parameters.

ILRIS terrestrial laser scanner

The Optech ILRIS is a fully portable laser-based ranging and imaging system for commercial mining, survey, engineering and industrial applications. With exceptional range, the ILRIS enables users to scan open-pit mines and mine environments, collecting rapid, accurate 3D data from a distance. A compact and highly-integrated instrument with digital image capture and sophisticated software tools, the ILRIS is field-ready and requires no specialised training for deployment.

With an on-board high-resolution digital camera and large-format LCD viewfinder, the ILRIS terrestrial laser scanner has a visual interface similar to that of a digital camera.

The Optech ILRIS is deployed by a single operator, with a rapid and simple setup. The scanner is controlled via a wireless handheld PDA or laptop computer during operation. The target area and scan status are displayed locally on the screen, and data is written directly to removable media. Measurement area and spot density are user-definable. The system’s large dynamic range and compact size ensure that high-accuracy surveys are completed quickly and safely.

Laser scanning for landslides and earth movement

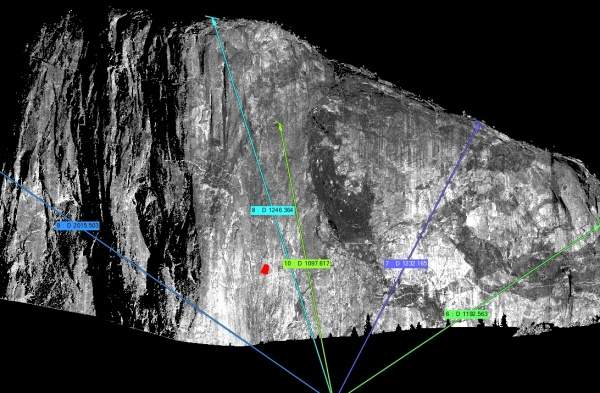

Lidar technology is highly useful in change detection because it acquires accurate and timely comparative measurements between separate objects, or of a single object over time. Lidar instruments can detect and measure earth movement, as when the Optech ILRIS was used to survey a landslide in an open-pit mine.

Using data collected from the same point over a three-week interval, a comparison was performed to look for slope movement. By quantifying the amount of material that had shifted and locating the area with precision, the Optech ILRIS confirmed that part of the mine was within a landslide-prone area.

The ILRIS produced a detailed report and JPG screen captures, and output an ASCII text file containing all comparison points and associated RGB colours generated by the comparison process. This file allowed further analysis by the operator.

The risk of landslides can now be assessed objectively as the Optech ILRIS provides continuous, accurate quantified measurements, thus greatly improving mine safety.

Mobile 3D mapping of open-pit mines

The Optech Lynx Mobile Mapper generates rich engineering-grade lidar and image data from moving vehicles at highway speeds. At the forefront of technology, the Lynx integrates the latest innovation in lidar sensors, with multiple perspective lidar imaging and best-in-class imaging, navigation, product warranty and support.

The Lynx performs rapid 3D mapping of any area open to a moving vehicle, including open-pit mines, infrastructure and buildings. It delivers unprecedented detail for corridor asset inventory and management (hydroelectric, roadway and railway). It also maps urban infrastructure such as storm and sanitary sewer systems, and is used in a broad range of applications including modelling of as-built structures and architectural studies/historical building preservation.

Commercial lidar systems

Based in Toronto, Canada, Optech is the global market leader in commercial lidar systems. We have operated since 1974 in the field of applied laser and electro-optical technology, specialising in the design and construction of innovative lidar systems. More recently we have developed a strong presence in high-performance aerial digital cameras, including thermal and multispectral cameras.

Optech lidars have been installed and used in mines around the world for more than 15 years. With rugged hardware, workflow software and global 24/7 support, Optech leads the world in advanced lidar and camera solutions for airborne, mobile and terrestrial surveying.