Monaflex Truck Tyre Repair and Vulcanising System

Monarch has more than 50 year's experience installing tyre repair systems for industries.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

At Monaflex we provide the highest quality tyre repair system in the industry, as well as a first-class training and support package, so you have everything you need for a top tier tyre repair operation.

Establishing the right tyre management plan and setup can be time-consuming and complex, but using our expertise as industry world leaders, we have streamlined the process and provide proven solutions tailored to your business. Whether you need help establishing a green field tyre repair operation, advice on how to optimise workshop efficiency or require bespoke training, we can provide effective solutions that increase the productivity of your tyres, save time and money, and fulfil your sustainability commitments.

We’ve been in the industry for over 60 years supporting global industries in mining, civil construction, agriculture, and road transport. Our team has worked with every conceivable type of tyre repair project, from one-man agricultural-focused operations to managing workshops at the world’s largest mines.

Our purpose is to share our expertise and experience so we can improve the safety and efficiency of your operations.

Our tyre repair system was the first of its kind and innovation and pioneering advanced technologies, are still at the heart of everything we do today.

We’ve built a reputation as trusted experts in the industry and we’re dedicated to finding the best solutions and products for you.

We can help you by…

A perfectly moulded repair that is the strongest in the industry.

Doing away with traditional heavy machinery, Monaflex developed a lightweight yet tough system that provides a distortion-free, long-lasting repair to tyres of all sizes.

Faster repairs

The Monaflex system is far quicker than other systems, as the required temperature for vulcanisation is uniformly applied to the repair area from both the inside and outside of the tyre. This means the patch and the plug can be cured at the same time. Curing time is quicker, which means less downtime for your vehicles.

Longer lasting repairs

Heavy-duty inflatable airbags provide consistent pressure allowing for total conformity to the profile of the tyre. The result is a distortion-free, feather edged repair which is stronger than any other.

Tough design, superior quality

Using durable heat pads and hard-wearing airbags, Monaflex operates a stringent manufacturing quality assurance system, from comprehensive testing of raw materials through to the issuing of individual ‘product passports’ to document pre-despatch testing. This process ensures all Monaflex equipment is ready to face the harshest environments with full warranty protection.

Portable and easy to use

Designed for easy assembly by a single operator, the Monaflex system can collapse down to a compact size making transport and storage easy. With no heavy metalworks, even the complete system for repair of the largest tyres in the world can be transported in the back of a regular car, making mobile repair services and multi-site operations a possibility.

A system tailored to your needs

With this system, you can lower initial setup costs by only purchasing the equipment you need to repair a specific range of tyres. You can always expand at a later date as your tyre range extends. The full Monaflex system will cover a wider range than any other on the market. Each system can repair the sidewall, shoulder and crown without the need for extra components.

Bead repairs

One of the most important components of a tyre is the bead. Without a functioning bead, a tyre simply could not stay securely on the rim, rendering it useless.

Beads can frequently be damaged during the mounting, dismounting or mechanical handling of tyres. The Monaflex system ensures a strong permanent repair. Using our system, loose rubber is buffed back and raw compound is applied to the area. This can then be properly cured using heat and pressure to the repair area from all sides of the bead*.

*Please note: Do not attempt repair if the bead cable is damaged. We recommend only rubber repairs are made and that damage to tyre body cords or bead bundles are rejected for repair.

Sidewall repairs

The environment in which dump trucks, wheel loaders, motor graders and other heavy mining equipment operate is severe, even on the toughest of tyres. One of the most common failure modes is sidewall damage.

Monaflex offers a range of dedicated sidewall repair systems which provide a rapid setup solution for operations seeing a high volume of this specific type of damage. With the addition of a metal frame, an operator can assemble the system in less than a minute.

Good for the environment and your budget

Having a comprehensive tyre management plan is important in extending the lifespan of your tyres, and is a critical factor for maximising your budget and productivity.

The Monaflex Tyre Repair System, along with our first-class training and support package, means you can extend tyre life by hundreds and even thousands of hours. Keeping tyres in service for as long as possible considerably reduces scrap and your carbon footprint.

More complex repairs means less scrap

Many repair systems fail to provide an effective solution for badly damaged tyres, but the Monaflex system ensures a strong permanent repair which remains as robust as the original tyre construction. Bead and sidewall damage would usually result in a tyre being disposed of however our specialised equipment can restore the integrity of tyre strength with a complete vulcanised repair which further reduces the environmental burden of disposal.

Monarch has more than 50 year's experience installing tyre repair systems for industries.

Monaflex pioneered the use of inflatable pressure bags to provide outstanding conformity to the unusual contours of a tyre. The result is a perfectly moulded repair that is one of the strongest in the industry.

Our team has worked with every conceivable type of tyre repair project, from one-man agricultural-focused operations to managing workshops at the world’s largest mines.

Managing assets in tyre repair operations.

There is a choice of options when it comes to filling the internal void of the tyre.

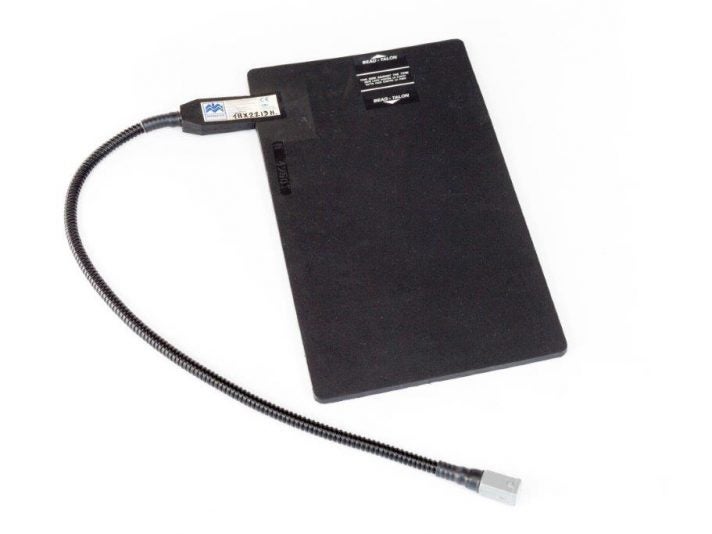

Multiple layers of reinforced heavy-duty, yet lightweight fabric prevents distortion of the Heat Pad while providing maximum protection of the element wire.

We asked our agricultural expert what factors needed to be considered when deciding between the two.

We are often asked how long a Monaflex system lasts or how many hours of service can be expected from each component.

Maximising the lifespan of your OTR tyres has a significant impact on budgets.

Many OTR tyres are discarded due to sidewall damage that is in fact repairable. The following tips from our experts focus on how to evaluate the damage.

Monaflex for all your tyre repair supplies requirements.

Effecting a perfect repair means your tyre can be returned to service whether that be haulage, loader, dozer, farming and logging, or over-the-road transport.

We’re continually optimising Monaflex components in response to usability testing and customer feedback. Have you seen our most recent changes?

Tyres are one of the most significant costs for mining operations. The cost of tyre ownership cannot be understated and as such tyres must be preserved.

Monaflex will be showcasing a new generation of vulcanization components, as well as providing an exclusive world preview of our brand new conveyor system at Electra Mining 2018.

Bead damage is a common problem in many operations we encounter and often, unnecessarily, results in many costly earthmover tyres heading for the scrap heap.

Our new generation of Heat Pads and Airbags are stronger, lighter and even more durable.

With the new generation of Monaflex conveyor repair systems, direct costs and resource requirements are vastly reduced:

Correct sidewall maintenance and repair is a crucial part of maximizing the lifespan of OTR tyres and minimizing time lost due to unforeseen issues and failures.

Three simple care tips to maximise the lifespan of your Heat Pads.

CONEXPO-CON/AGG 2017 promises to be huge!

In February, we'll be heading to the Tire Industry Association's Off-the-road Tire Conference, which this year is located in Oahu, Hawaii.

The pressure on organisations to minimise downtime and decrease expenditure is ever increasing, and to many the essential, yet costly and time-consuming area of conveyor belt maintenance is challenging.