Hexagon Mining has released major improvements to the MineSight Schedule Optimizer (MSSO) in Version 9.6.

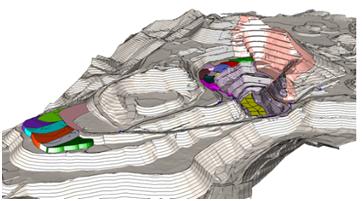

Part of Hexagon Mining’s MineSight Planning Suite, MSSO determines the most productive cut mining sequence to achieve the highest project profitability. This versatile scheduling tool satisfies a variety of project quality, quantity, market, and geotechical constraints, as well as destination capacities, equipment resources, and economic parameters. Advanced integer programming engines are used to solve blending and scheduling problems.

Version 9.6 now fully supports stratigraphic models, also known as Gridded Seam Models (GSM). GSMs are most commonly used for flat-lying deposits and metal vein deposits. Mining geometries (polygones or solids) can be imported into MSSO either from MineSight 3D viewer or from an existing MineSight Planner project.

Through integration with MineSight Reserve, reserves associated with the geometries along with a list of mining seams available in the GSM are used for proper reserve allocation. Version 9.6 introduces cash flow constraints, allowing you to define cash flow limits. It also allows for customised benching with options for defining elevation range for polygonal geometries. Other highlights include:

- Advanced constraints relaxation

- Fixed cost by phase and destination

- Ability to export cut geometry to MineSight 3D (MS3D) objects and MS3D End-of-Period tool

- Speed improvements for reserves calculation

"These latest improvements build on MSSO’s reputation for empowering mine engineers to generate the most operational mining schedules," said MSSO product manager, Samira Kalantari. "Recent enhancements for stratiform models make MSSO a formidable mine planning and scheduling product for all different types of mines and deposits."