ReconEng is a diversified engineering group providing mechanical design, industrial automation, project implementation and commissioning services for a wide array of clients in mining, manufacturing and oil and gas sectors.

We are a leading Australian developer of special purpose automated process solutions specializing in cold-cutting, plasma-cutting, materials loading, feeding and conveying. We are also an Australian OEM with products sold Worldwide.

We are experts at solving Engineering problems. If you have a difficult, costly or time consuming process, we can more often than not provide a multi-system integrated solution, involving traditional and modern design such as robotics, vision systems, software / database integration and more.

Rio Tinto expansion projects (AutoHaul, ECP, DA)

Tier-one supplier of complex mechanical design, components and steelwork for Rio Tinto AutoHaul, ECP and DA projects. Onsite design, multi-systems and maintenance processes integration, project management, production and supply of more than 7,000 parts and 90t of material for the projects.

IntelliDrill: high-capacity lab samples collection

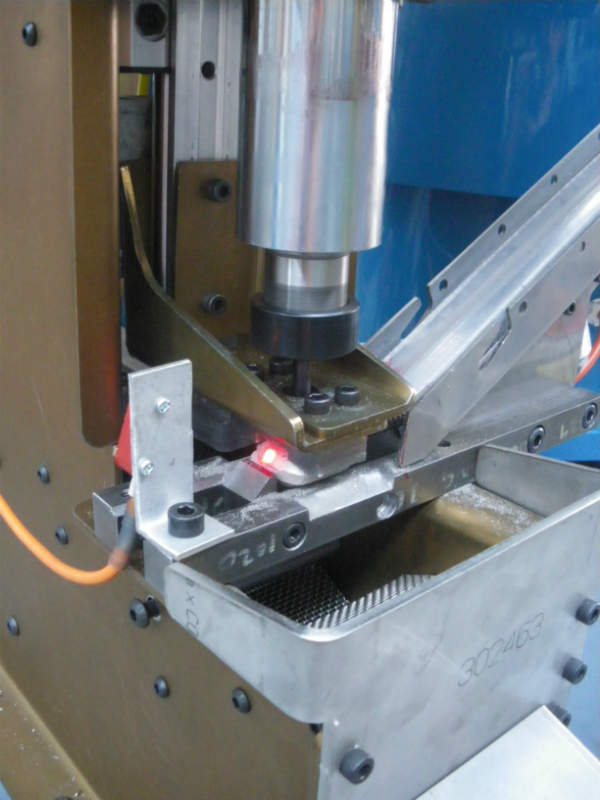

We provide automatic solutions for continuous, labour-free drilling of Nickel briquettes and collection of swarf samples for lab analysis.

The system was designed for drilling and collection of Nickel shavings for batch content analysis, replacing previous labour-intensive manual process.

Its fully automatic operation achieved 800% productivity improvement, significantly reduced associated labour, and greatly improved operational safety.

Full project design, research, development, implementation, and on-site installation, implementation and commissioning are carried out.