Laser Distance Spectrometry presents MAYA, a fundamentally new online laser analyser of the chemical composition of mineral materials on conveyor belt.

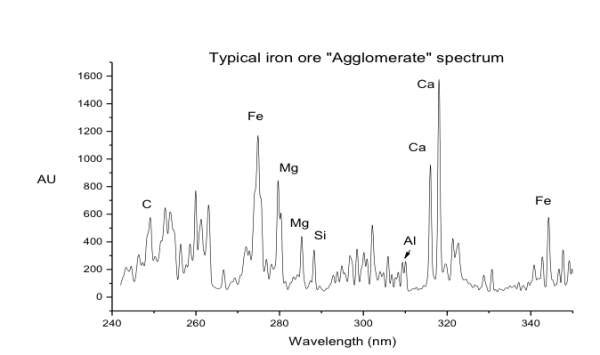

MAYA uses laser-induced breakdown spectroscopy (LIBS) technology, the safest and most universal method of elemental analysis. LIBS has been increasingly replacing older, more hazardous techniques, such as prompt-gamma neutron activation analysis (PGNAA) and X-ray fluorescence (XRF) in both laboratory and online applications.

Advantages of online analysis: real-time data and prompt technological control

Raw mineral materials’ chemical composition varies significantly. This is one of the main problems of the mining industry since it makes the composition of raw mixtures unstable. Traditionally, laboratory analyses have been used to determine the composition of the material of interest. However, these analyses, made once in several hours, often provide the necessary information too late, after the material has already been processed, and are not helpful in technological decision-making.

24/7 online measurement of elemental composition of material allows monitoring the concentration of major elements and contaminants. This provides multiple improvements of industrial processes, including the following:

- Improved quality and sales price of the finished product through stabilisation of the composition of raw materials and/or discharge of off-grade/impurities

- Increased production due to mixing rich concentrate with poor concentrate, and thus obtaining stable and optimal input into the process

- Reduced energy consumption

- Reduced pollution

- Decreased positive tolerance of the main elements in the product

- Reduced rejection rate of the finished product

Integration into an automatic control system

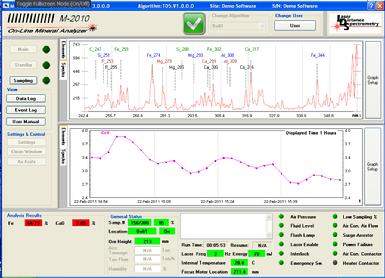

MAYA’s fully automated operation eliminates possible human error. The analyser can be integrated into an automatic control system. The analyser, installed above the conveyor belt with crushed ore or other material, transfers data on the composition of the material in real-time to the enterprise’s SCADA system, which controls the operating mode of the sorting or dosing equipment. Interface with the existing SCADA systems is established through any standard currently in use (analog signal 4-20 mA, Excel file, MySQL, MSSQL, OPC server).

Alternatively, MAYA can be used in indication mode to perform manual reading and control. This way, it is possible to make immediate rejection decisions in case of serious but temporary contaminations, such as large pieces of dead rock, which, after being crushed, appear as 15m-30m long segments on the conveyor belt and can significantly affect the quality of the final product.

Advantages of MAYA in the mining industry

MAYA:

- Provides remote elemental analysis with no sample preparation

- Simultaneously analyses many elements, detects light elements

- Provides high sensitivity and accuracy, which do not depend on the size of the analyzed piece, the quality of its surface, or the overall thickness of the layer of the material on the conveyor belt

- Has low limits of detection (LOD) as a result of clear spectral lines of many elements of interest in a wide optical wave range

- Does not use X-rays, Gamma rays, or neutron radiation and is therefore absolutely safe for personnel and the environment

- Does not require obtaining environmental permits, maintaining strict safety measures, and undergoing inspections, which are normally required for nuclear technologies. With MAYA, protective goggles are the only required safety measure

- Has the lowest operating expenses among currently used online methods

- Operates 24/7 all-year-round under true industrial conditions.

Expertise and efficient industry-specific solutions

Please visit our website and contact us anytime. We will be happy to answer your questions. Our team of leading scientists and technicians with expertise in laser detection systems will provide you with an efficient industry-specific solution.