Esser-Werke

Wear-Resistant Conveying Pipe Systems

Esser-Werke produces highly wear-resistant conveying pipe systems based on double-layer pipes and components.

Subscribed

You have successfully submitted your enquiry. Someone from our company will respond ASAP

About Us

Esser-Werke produces highly wear-resistant conveying pipe systems based on double-layer pipes and components.

The company has been leading the way in the mining industry for more than 60 years and also offers single-layer hardened systems and unhardened steel qualities for medium and low wear resistance applications.

Our products are developed in close association with our customers and are customised in accordance with their requirements. In numerous industrial applications our Twin Pipes trademark has become synonymous with maximum wear resistance and quality.

Delivery pipes, conveyance elbows, reducer pipes and components

Esser-Werke’s extensive product range includes items such as delivery pipes, conveyance elbows and reducer pipes, as well as special components developed in accordance with our customers’ requirements.

We supply companies such as concrete pump manufacturers and operators, mining companies, sand and gravel quarries, chemical industries, glassworks, plant engineering, and many more who use highly-wear resistant pipe components for the conveyance of abrasive media.

Transportation of abrasive mining construction materials

Our products are particularly used in underground mining and civil engineering for the transportation of highly abrasive construction materials such as tailings, as well as dust and ash which are being transported for underground disposal. This is done either pneumatically or hydraulically using operating pressures of up to 200 bar.

Backfilling applications and hydraulic conveyance in opencast mining

In opencast mining, Esser-Werke’s products are commonly used for backfilling applications as well as for hydraulic conveyance of gravel and sand. Our services and performances include:

- Conveyance pipe component layout according to customer application requirements

- Development, design and construction according to manufacturer-specific requirements

- Static calculation of shaft and section lines

- Wear tests and assessments

- Profitability calculations

Pipe connections for the conveyance of abrasive media

With particular expertise in the conveyance of abrasive media our company offers unrivalled expertise in the field of pipe connections. When it comes to highly-stressed piping components, this sensitive area is often a crucial factor for the success of a mining operation. Esser-Werke’s practically gap-free and offset-free connections serve to significantly reduce any potential turbulence in this area.

Our special type wear and tear protected connections, enhanced welding technology for tempered pipes (deep frost welding) and our sophisticated double-layer pipes enable us to achieve outstanding service lives.

Single-layer hardened pipes

For medium wear-resistance requirements, our induction hardening machine enables us to produce single-layer hardened pipes with a nominal diameter of DN125. This product is sold under the trademark ESSER 400.

Where previously untempered mild steel pipes with a wall thickness of 7mm to 9mm had to be used, we can now achieve the same service lives with 4mm to 4.5mm thick pipe walls, thus reducing costs and facilitating assembly.

Wherever, for example, 4mm mild steel pipes are used, we are able to double the service life by use of hardened pipes of the same wall thickness, with extra costs only amounting to approximately 30%-40%.

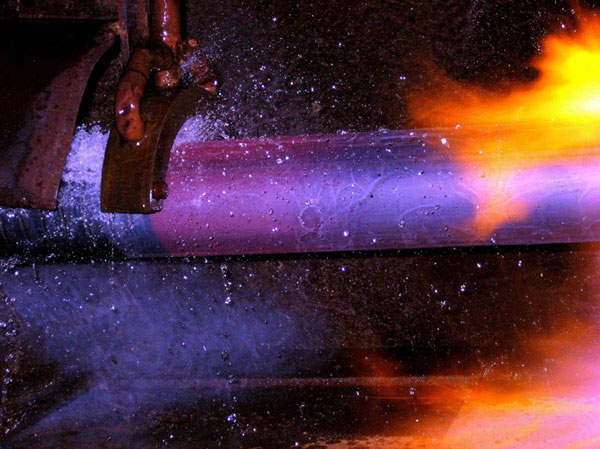

Pipe diameters up to DN 200 with larger wall thicknesses are processed by flame hardening. Here too, we are able to achieve at least twice the service life compared to normal steel pipes.

Pipes, compensators and components for mining applications

As a rule, our systems are manufactured using all types of standard connections and common pipe dimensions up to DN 200. Our product range includes:

- Delivery pipes

- Conveyance elbows

- Reducer pipes

- Compensators

- Support pipes

- Bracket pipes

- Branch pipes

- Special components according to customer requirements

About Esser-Werke

Esser-Werke was founded in 1948 under Westmontan-Werke GmbH, originally specialising in pipes for the coal mining industry. The company changed its name to Esser-Werke in 1954, before launching its twin pipe products in 1980.

Today, Esser-Werke has around 80 employees working at its Warstein headquarters in Germany and is affiliated with companies LTB in France and Esser Pipe Technology in the US.

Contact Details

Website

Email Address

Address

59581 Warstein,

Germany