CIMA Impianti was established in 1953, and originally specialised in the manufacture of moulds for tyre retreading. In the following years it widened its range of products, and extended to the manufacture of curing presses in the national market.

During the 70’s, with the introduction of tyres with radial casing, the first presses of the Radial Pneus series were developed and manufactured. These were the first and, for many years, the only presses conceived for this type of tyre.

This advancement awarded the company recognition for its innovation and CIMA Impianti was introduced into the international markets. CIMA has since become a leading provider of turnkey plants for tyre retreading.

SAFE TYRE RETREADING EQUIPMENT

Today’s mission is to supply customers reliable high-quality equipment, covering all retreading needs. CIMA ensures that these are developed in compliance with both customer expectations and relevant safety requirements, assuring constant presence and assistance. The company also offers a competent after-sales service, which assures the availability of spare parts and skilled labour on a global basis.

RP SERIES: VULCANISING PRESSES

The CIMA RP series of vulcanising presses allows the retreading of tyres for a range of purposes including:

- Aircraft

- Passenger car and 4×4

- Light truck

- Medium and heavy truck (including the new Super Singles)

- OTR

- Agricultural

The moulds can be heated by means of electricity, steam or diathermic oil. For the internal inflation air, steam, circulating or static hot water, nitrogen and mixtures of them can be used. This range enables customers the flexibility to choose the most suitable method for their business.

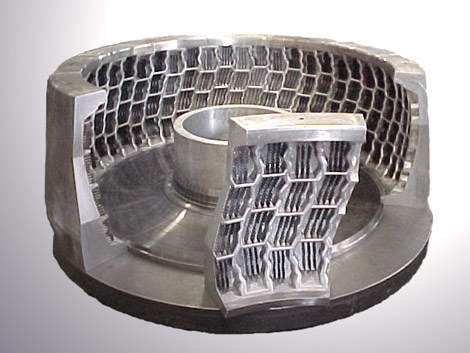

CROSS-PLY AND RADIAL TYRE MOULDS

CIMA Impianti specializes in the manufacture of moulds for cross-ply and radial tyres in any configuration. These include moulds in two halves, segmented (cylindrical and conical) suitable for any type of curing press and flat moulds for pre-cured rubber bands. The available sizes range from motorcycle to OTR tyres.

One of the main strong points of CIMA is the capacity to correctly size up the internal dimensions of the moulds, based in most cases on buffed casings supplied by the customer. This skill, combined with a well organised production process enables the company to meet the specific requirements of its customers.

OTR TYRE RETREADING

Following the fast growing market of OTR tyre retreading, CIMA has recently developed and sold two new sizes of fully automatic curing presses for OTR tyres.

The two new models, RP 11 and RP 14, have the capacity to retread tyres from 35in up to 49in (including 45/65R45 and 27.00R49) and from 57in to 63in, respectively.

This new style of machines incorporates all the positive features of the well-proven CIMA RP series, including the perfectly radial segment closing and opening movements and the mould locking mechanism offering unsurpassed finish and quality of the retreaded tyre.

Thanks to the constant information exchange with the final users, the design of the presses has been developed to make the new equipment as user friendly as possible, incorporating up-to-date and modern solutions, such as the press lid incorporated in a ‘gantry’ system. These two presses are the natural conclusion of the automatic CIMA press range that now covers any tyre size available on the worldwide retreading market.

TUBELESS TYRE PRESSES

The two presses are the result of CIMA’s latest investments in research and development, and have been designed to operate with the well-tested CIMA tubeless system, which can be combined with inflation by air, steam, nitrogen or a combination of them.

NOT ONLY CURING PRESSES

CIMA, today offers one of the widest ranges of products for tyres retreading in the world, including:

- Casings inspection machines

- Buffing, peeling machines

- Extruders and builders

- Regrooving machines

- Autoclaves