The Zero Carbon Lithium project is a geothermal lithium brine project in the Upper Rhine Valley region of Germany. The project is being developed in phases by Vulcan Energy Resources (Vulcan), an Australia-based exploration company.

The first phase is focused on the Taro licence while phase two will involve the development of the Ortenau licence area.

Vulcan previously held a 51% interest in Taro while its joint venture partner Global Geothermal Holding (GGH) held the remaining interest in the licence. The company signed a binding agreement to acquire 100% of GGH in February 2021. The acquisition was completed in the first half of 2021.

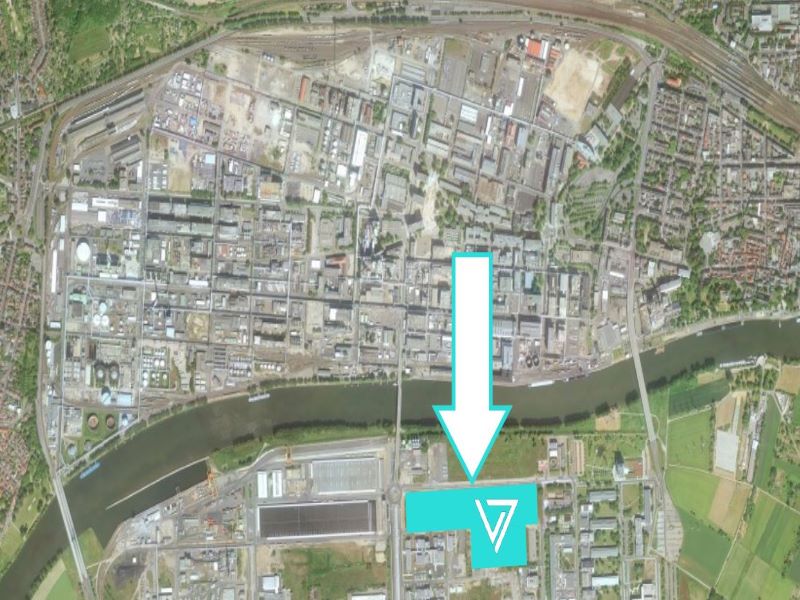

Vulcan reached an agreement with German industrial site management company Infraserv to acquire the site for the commercial lithium hydroxide plant (Central Lithium Plant or CLP) of the project in September 2021. The proposed site is located at the Höchst Chemical Park (Industriepark Höchst), just outside of Frankfurt, Germany.

A pre-feasibility study (PFS) for the lithium project was announced in January 2021. It envisions an eco-friendly lithium extraction method with a net-zero carbon footprint and a project life of 30 years.

A definitive feasibility study (DFS) is in progress and the project is expected to start commercial production by 2024.

Zero Carbon Lithium project location and geology

The Zero Carbon Lithium project is located in the Upper Rhine Valley of south-west Germany. It is situated within the Upper Rhine Graben (URG), which is characterised by Cenozoic graben comprising sedimentary rocks of Permian to Tertiary era with minor Tertiary volcanism and Quaternary surficial deposits.

The project focuses on brine-bearing aquifers associated with the sandstones of Lower Triassic Buntsandstein and Permocarboniferous Rotliegend groups, which are together known as Permo-Triassic strata.

Zero Carbon Lithium project mineralisation and reserves

The lithium mineralisation at Taro is hosted within confined, subsurface aquifers associated with the Permo-Triassic strata sandstone at depths ranging between 2,165m and 4,004m below the surface. Mineralisation at the Ortenau licence occurs within confined, subsurface aquifers of the Lower Triassic Buntsandstein Group sandstone at depths between 2,165m and 4,004m below the surface.

Probable reserves were estimated at 1.12 million tonnes (Mt) of lithium carbonate equivalent (LCE) grading 181ppm of lithium, as of January 2021. Indicated and inferred mineral resources were estimated at 15.85Mt of LCE grading 181mg/l of lithium.

Mining and processing at Zero Carbon Lithium project

The lithium extraction from underground aquifers at the Zero Carbon Lithium project is proposed to utilise deep geothermal wells drilled to depths ranging between 2km and 5km to pump hot, mineralised brine to the surface. Cones of depression developed around the wells will allow the brine to flow into the well.

The project will use direct lithium extraction (DLE) methods to extract lithium from the brine solution. The brine will be pre-treated and purified to extract lithium using a sorbent to produce lithium chloride concentrate.

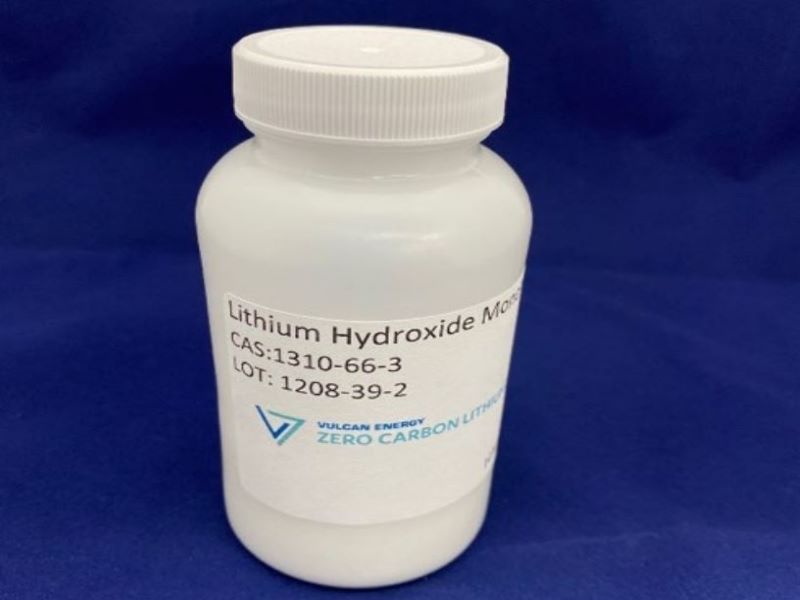

The concentrated lithium chloride eluate will be transported to the CLP where the solution will be purified and converted into lithium hydroxide solution using electrolysis. The solution will undergo crystallisation and purification processes to produce the final lithium hydroxide monohydrate (LHM) product.

Testing and pilot plant

Vulcan partnered with water filtration and purification specialist DuPont Water Solutions (DuPont) to test and scale-up DLE for the project in February 2021. DuPont will support Vulcan with test work during the definitive feasibility study.

A pilot plant to demonstrate DLE from the project became operational in April 2021 while the first battery-quality lithium hydroxide was produced from the pilot operations in September 2021.

Geothermal power plants at the mine site

The Zero Carbon Lithium project will co-produce geothermal energy and lithium hydroxide. The same renewable energy will power the lithium extraction process.

The project is expected to have five geothermal plants, including three at Ortenau and two at Taro, to produce 74MW of renewable energy in total using heat from the deposit.

Off-take agreements

Vulcan signed an off-take agreement with cathode materials manufacturer Umicore for the supply of lithium hydroxide from the project in October 2021. The agreement will allow Umicore to buy up to 42,000t of battery-grade lithium hydroxide over an initial five-year period from 2025.

A supply agreement was also signed with LG Energy Solution (LGES), a South Korea-based producer of lithium-ion batteries for electric vehicles, in April 2021. It includes an initial five-year term with the option to extend for five more years. LGES will purchase 5,000t of battery-grade lithium hydroxide during the first year and 10,000t a year from the second year onwards. Deliveries are expected to begin from 2025.

Vulcan and automotive company Renault signed a five-year strategic partnership for the supply of between 6,000t and 17,000t of battery-grade lithium hydroxide a year in August 2021. The agreement includes an option to extend the supply term.

Contractors involved in Zero Carbon Lithium project

The processing plant design, engineering, and cost estimates for the PFS were provided by global engineering company Hatch. The company was also engaged as the engineering consultant for the lithium chemicals part of the DFS. It is, further, responsible for the engineering and execution planning for the DLE plants and CLP.

German company Geothermal Engineering (Geo-T) conducted the geothermal subsurface study and the well production study as part of the PFS, while the mineral resource modelling and estimation were provided by APEX Geoscience.

Energy consulting firm GLJ performed the ore reserve estimate review. It was also contracted to serve as the engineering consultant and compile the overall report and economic modelling as part of the DFS.

German firm gec-co Global Engineering was engaged to provide engineering studies for the geothermal plant for the PFS. The company was also engaged to provide geothermal above-surface engineering and development, including permitting, as part of the DFS. The geothermal and geological below-surface engineering and development will be handled by GeoT.

Australian consulting firm Optiro performed the economic analysis for the lithium project.