Conveyors Plus

Conveyor Belt Alignment Tracking Systems

Subscribed

You have successfully submitted your enquiry. Someone from our company will respond ASAP

About Us

Conveyors Plus has developed the industry’s most cost-effective belt alignment tracking system. With its simple yet innovative design, we are confident that it will show immediate results and save your company money.

Simplicity is not just in its operation but also in its installation. Our conveyor alignment system replaces existing return rollers and uses existing return bracket bolt holes for the installation of the Sure Align Tracker.

Change out of a worn steering roller is quick and easy. The Sure Align Tracker installs quickly and easily, avoiding the high costs of downtime.

Conveyor alignment system for the mining industry

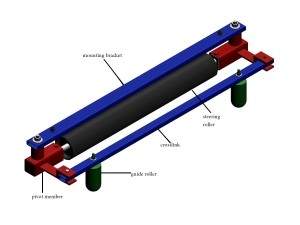

The Sure Align Tracker consists of only five components that work continuously to keep the conveyor belt aligned. Under-belt, return-side installation minimizes exposure to damaging debris and ensures positive contact and tension on a clean belt. Quality construction and simple design will withstand the world’s harshest conditions. The Sure Align Tracker uses five components:

- Pivoting members (2)

- Cross-link assembly

- Mounting bracket

- Guide rollers (2)

- Rubber lagged steering roller

Since 2004 we have successfully installed and maintained our systems in the mining, aggregate, power plant and bulk material handling industries.

Simple installation of the belt alignment tracking system

Realize immediate cost savings through extended conveyor belt life expectancy, less downtime, less spillage and improved maintenance.

Since 2004, we have successfully installed and maintained our products within such companies as BHP, Xstrada, Barric, Rio Tinto, Debeers Diamond Mines, Lafarge, Vale, FMI, PCS Potash, Gold Corp, Briggas Gold, and many others.

Installation involves the removal of an existing roller and replacing the roller with the Sure Align Tracker. The Sure Align Tracker belt alignment tracking system uses existing mounting brackets on the conveyor belt frame. No special tools are needed.

Benefits of the Sure Align Tracker

The Sure Align Tracker belt alignment tracking system offers users many advantages, including:

- Quick and easy installation, minimizing downtime

- Continuous, consistent and reliable belt alignment

- Return side application means the components are better protected from wear and damage of the dirty side of the belt

- Increased conveyor belt life expectancy

- Reduced spillage and waste

We’re so confident in the Sure Align Tracker that we guarantee results. Contact us today to book an evaluation and let us show you what the revolutionary Sure Align Tracker will do for your operations.

Contact Details

Website

Email Address

Address

Timmins,

Ontario,

P4N 7C2,

Canada