Sprung Structures is a leading provider of tensioned-membrane structures in the pre-engineered construction industry, building more than 12,000 buildings in more than 100 countries.

The company operates in various sectors, including mining, military, education, health care, sports and recreation, energy, manufacturing, warehousing, aviation, community, film, and hospitality.

Structures to Withstand Extreme Conditions

Sprung Structures’ products are built to withstand hurricane-strength winds and are engineered for extreme climates proven to withstand severe weather such as tropical storms, blizzards and sandstorms.

They can be reconfigured, expanded, disassembled, and relocated, are built within weeks and with minimal foundation requirements.

Sprung has successfully completed several noteworthy projects over the years, including the design and delivery of an emergency hangar for NASA’s space shuttle program in the late 1980s and the development of a first responder facility at Ground Zero for the relief effort at the World Trade Center following the terrorist attacks in 2001.

However, nothing catapulted Sprung to fame faster than when Elon Musk came calling in 2018. Within weeks, Sprung built a 150,000-square-foot assembly plant, which today is one of California’s largest manufacturing facilities and continues to produce close to one million Tesla vehicles a year.

Other high-profile clients needing immediate building solutions include Apple, Blue Origin, Boeing, Eli Lilly, Exxon, Google, Rio Tinto, Fluor and Bechtel.

Advanced building construction technology

Sprung has revolutionized the way temporary and permanent buildings are designed and built, delivering structures that are world-class. Engineered to last, these clear-span structures shed snow, withstand hurricane-strength winds and are resistant to earthquakes. They can be reconfigured, expanded, disassembled and relocated after many years of use. They can also be built within weeks and have minimal foundation requirements.

With rapid construction capabilities, total design flexibility, exceptional durability and lower overall costs, Sprung structures offer a clear and cost-effective advantage over conventional construction. These high-performing structures also feature ample space, natural light and superior climate control, making them ideal for businesses seeking fast, affordable and efficient building solutions.

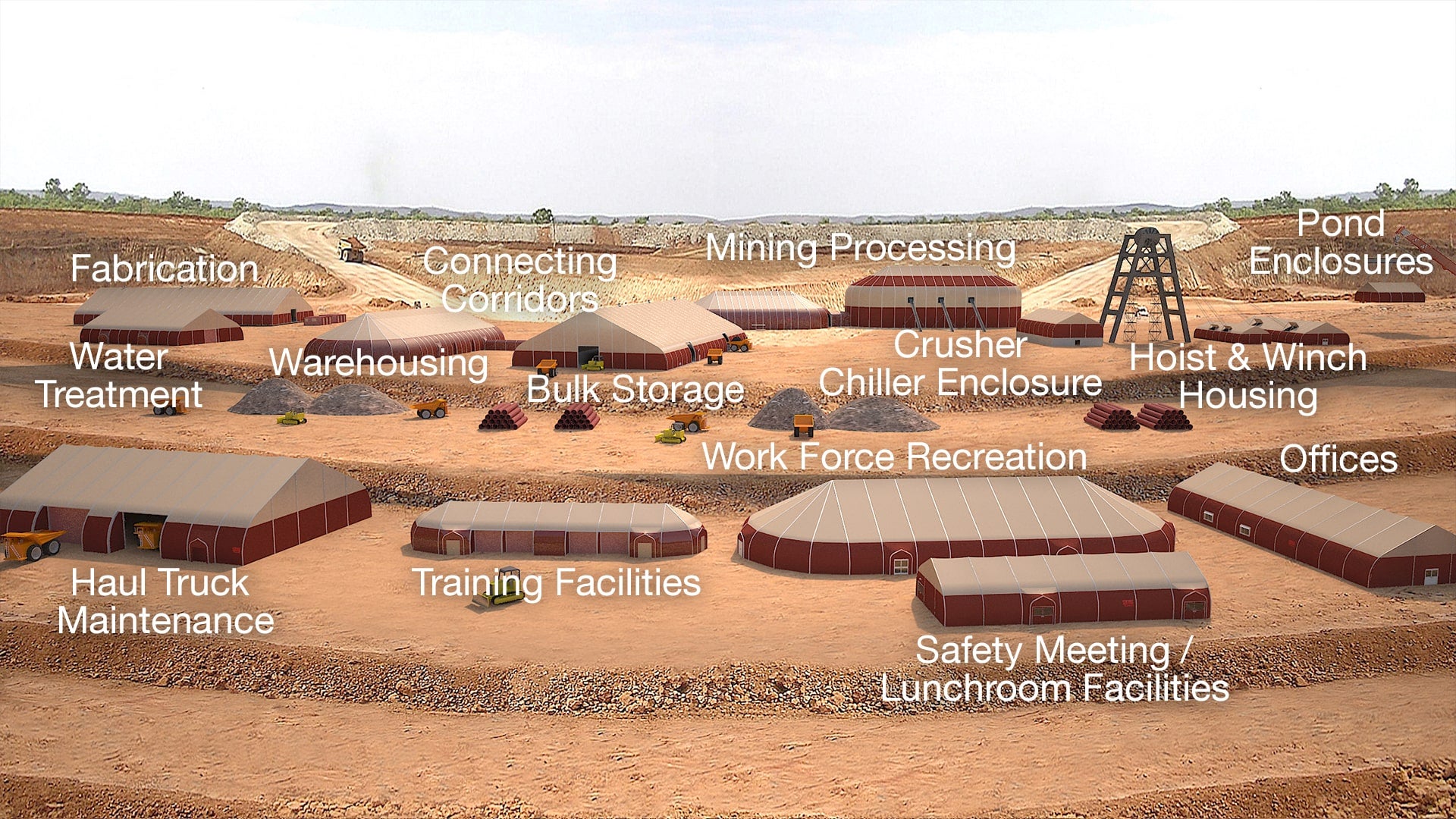

Mining Solutions from Sprung Structures

Sprung has been creating building solutions for over 130 years. Today, with over 12,000 Sprung structures around the world, we have been able to provide thousands of organizations across multiple industries with a faster, more flexible, cost-effective building solution that meets their needs and creates unlimited possibilities.

For decades, Sprung has been supporting the mining industry with the most reliable tension-membrane structures on the market in all environments. Our patented tensioning system provides reliability in extreme wind loads, and our proven high-performance insulation system and relocatable design will meet virtually any demand on site.

From dining halls, bulk storage buildings, haul truck maintenance, warehouses, and processing facilities, gymnasiums, and aircraft hangars, Sprung has done it all.

When our clients are under rigid timelines or have limited foundation requirements, a Sprung structure is the only solution. Under extreme weather conditions, our structures can withstand the hottest and coldest climates on the planet. Sprung Structures are engineered site-specific to manage extreme wind loads, certified up to 160 miles an hour.

Our corrosion-free aluminum substructure saves in shipping costs, especially when compared to steel, ships in compact containers to remote locations immediately, and is set up in a matter of weeks, not months.

Sprung Structures provide unmatched reliability and longevity; our structures are engineered to last for the entire life of a mine, with a 25-year pro-rata guarantee on the tensioned fabric and a 50-year pro-rata guarantee on the aluminum substructure. Our patented tensioning system and aluminum substructure significantly outperform low-cost galvanized steel alternatives.

The relocatable and modular design of a Sprung, along with its ability to be crane-lifted into place, allow it to adapt to virtually any mining facility application. Our optional, high-performance insulation package provides comfortable, spaces for a wide variety of mining infrastructure.