The Volta Grande gold project is an advanced-stage exploration project located near Altamira in Para State, Brazil. It is fully owned and operated by Canadian company Belo Sun Mining.

The Brazilian Government granted the construction licence for the project in February 2017.

A positive pre-feasibility study (PFS) of the project was announced in May 2013, while the preliminary economic assessment (PEA) was completed in February 2014. The feasibility study (FS) for the project was completed in March 2015.

The FS estimates the mine to require an initial $298m capital investment, including pre-production costs, while the average annual production at the mine is estimated to be 205,000oz over its 17-year lifetime.

Belo Sun Mining received an interim suspension order from the regional court to suspend the construction license of the project in April 2017. The suspension will be lifted, once Indigenous Affairs Agency of Brazil (Funai) approves the indigenous study conducted by the company.

Commercial production is expected to commence between 2018 and 2019.

Geology and mineralisation at Volta Grande

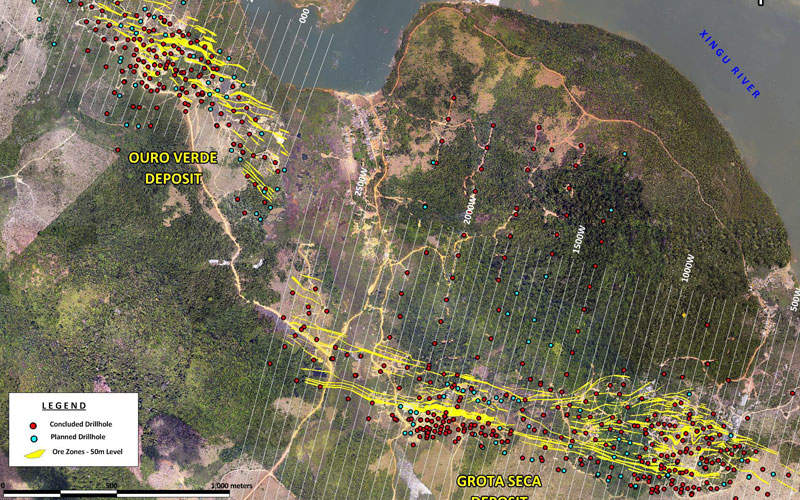

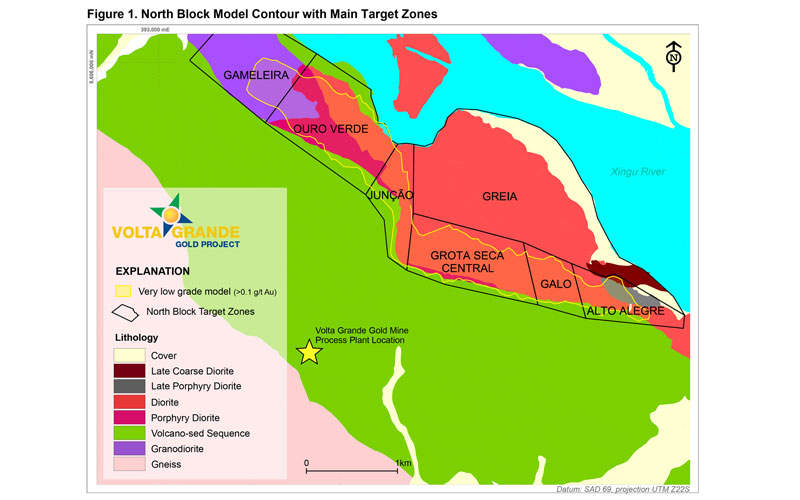

The Volta Grande project is mainly composed of two target areas, namely North and South blocks. The North block contains four mineralised areas, namely the Ouro Verde area, the Grota Seca area, the junction area between Grota Seca and Ouro Verde, and the Greia area. The South block comprises three areas namely Pequi, Grande and Itata.

Gold mineralisation at the mine occurs in two types, while primary gold occurs in intrusive rock and secondary gold occurs in saprolitic rock. Primary gold mineralisation occurs in a 300m-wide alteration zone, which extends the contact zone between the intrusive and the meta-sedimentary rock. Gold can be found in a stack of mineralised zones varying in size.

The mineralisation zone in Ouro Verde area extends for 1,100m to a vertical depth of 540m, while it extends for 2,900m and to a vertical depth of 400m in the Grota Seca area.

Reserves at the Brazilian gold mine

As of March 2015, the mine was estimated to contain proven and probable reserves of 115.97Mt graded at 1.02g/t Au, and 3.78Moz of gold.

Proven reserves are estimated to be 41.75Mt graded at 1.07g/t Au and containing 1.422Moz of gold. Probable reserves are estimated to be 74.21Mt graded at 0.98g/t Au and containing 2.346Moz of gold.

Mining and processing of gold at Volta Grande

The Volta Grande gold project will be mined using conventional open-pit mining techniques involving trucks, drills and loaders. The mine will initially have a design capacity of 3.5Mtpa of mill feed, which will reach full production of 7Mtpa in the third year.

A processing facility with a capacity of 3Mtpa in phase one for the first seven years of production will be constructed. It will be expanded to a nominal capacity of 6Mtpa from the ninth year to the end of mine life.

Gold will be recovered in a conventional recovery process that will include crushing, grinding, gravity recovery with intensive leach, cyanidation of slurry in carbon, electro-winning, carbon regeneration, and cyanide detoxification.

The processing plant will feature a milling area, pebble crushing area, gravity circuit, pre-leach thickener, leaching and cyanide leach and carbon-in-pulp (CIP) area, elution and carbon regeneration, gold room and reagents areas.

An estimated 93% of the gold will be recovered over the life of the mine.

Volta Grande gold mine infrastructure

The mine can be accessed from the Altamira city through a 60km road, of which 30km is a paved road. The remaining 30km will be upgraded and paved once the mine becomes operational.

Power to the site will be supplied from a substation located 20km north of the project on the site of one of the world’s biggest hydroelectric dams. The substation will supply power to the project site through a 230kV power line.

Two main diesel generators will act as additional power generators for the project, while a third generator is dedicated to the operation of rock saws.

Water for the plant will be supplied from the wells located on the property as well as from the Xingu River. Water from the wells will be treated using chlorine and stored in a water tower outside the camp.

Surface run-off and precipitation will also be captured to serve the project’s water requirements.

Consultants involved

The scoping and feasibility studies of the project were compiled by Lycopodium Minerals Canada with suggestions from a number of consultants including SRK Consulting, SGS Chile, HDA Servicos, Pocock Industrial, GH Wahl & Associates Consulting, Orway Mineral Consultants, JS Analytical Laboratory Consultants, McClelland Laboratories, JK Tech, AGP Mining Consultants, VOGBR, BGC Engineering, Environmental Resources Management, Dalben, Transglobal, and L&M Assessoria Empresarial (L&M).

The PFS for the project was compiled by AMEC Americas with inputs from other specialised consultants.

Contractors

FLSmidth was awarded an engineering, procurement and construction (EPC) contract by Belo Sun Mining for the first phase development of the Volta Grande gold mine in February 2017.