The NORI-D polymetallic nodule project is a proposed deep-sea mining development being undertaken by the Metals Company (TMC) with partner Allseas through Nauru Ocean Resources (NORI), a wholly owned subsidiary of TMC.

In August 2025, TMC published a pre-feasibility study (PFS) for NORI-D, including an initial assessment study that also considered the development potential of resources in the Tonga Offshore Mining and wider NORI contract areas beyond NORI-D.

The PFS sets out a phased plan, with wet nodule production projected to ramp up to 12 million tonnes per annum (mtpa) within five years of start-up.

Initial capital is estimated at approximately $4.9bn (C$6.63bn) for an 18-year life of mine, with first production targeted for the fourth quarter of 2027 (Q4 2027).

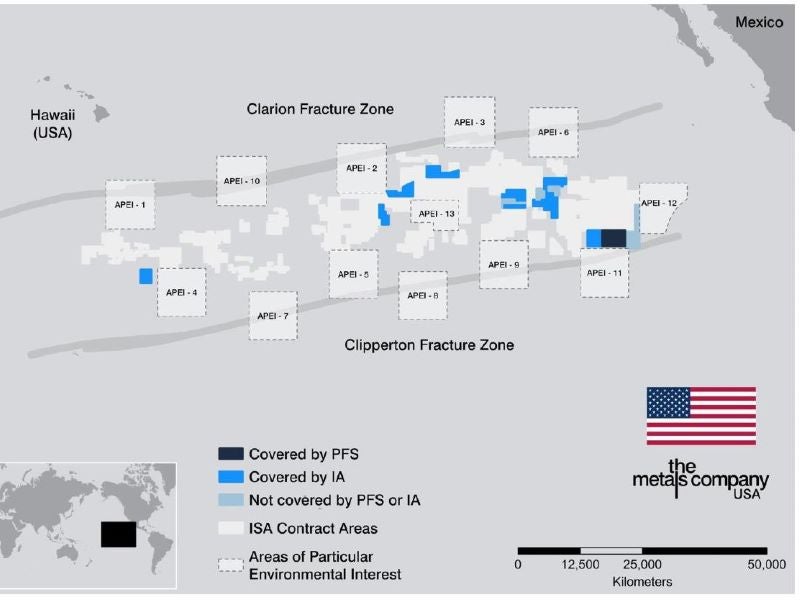

NORI-D location

The NORI-D polymetallic nodule project is located in the Clarion-Clipperton Zone (CCZ) between Hawaii and Mexico in the Pacific Ocean.

Geology and mineralisation

The CCZ seabed lies within the abyssal plain, the world’s most extensive physiographic habitat, spanning roughly 70% of ocean basins and around 30% of the Earth’s surface. The zone is intersected by ridges thought to have developed through seafloor spreading.

Sediments from the CCZ consist mostly of clays and siliceous biological casts. Sands and larger sediments are not generally found so far from land, and the commonly formed carbonate biological casts dissolve on the sea-floor in these deep-water regions faster than they accumulate.

Nodule geochemistry shows only minor variation across the CCZ. The estimated spatial distribution of nickel, cobalt, copper and manganese grades within the CCZ remains highly consistent and exhibits limited variability even over very large distances.

Copper and manganese concentrations tend to rise towards the south-east, cobalt is generally elevated in the north, and nickel is typically higher in the central and south-western parts of the CCZ.

Reserves

The probable mineral reserves at NORI-D are estimated at 51 million tonnes (mt), with average grades of 0.13% cobalt, 1.1% copper, 31% manganese and 1.4% nickel as of August 2025.

Mining method

The proposed mining approach for NORI-D involves a phased development plan deploying twin 15m-wide seabed collectors to gather nodules.

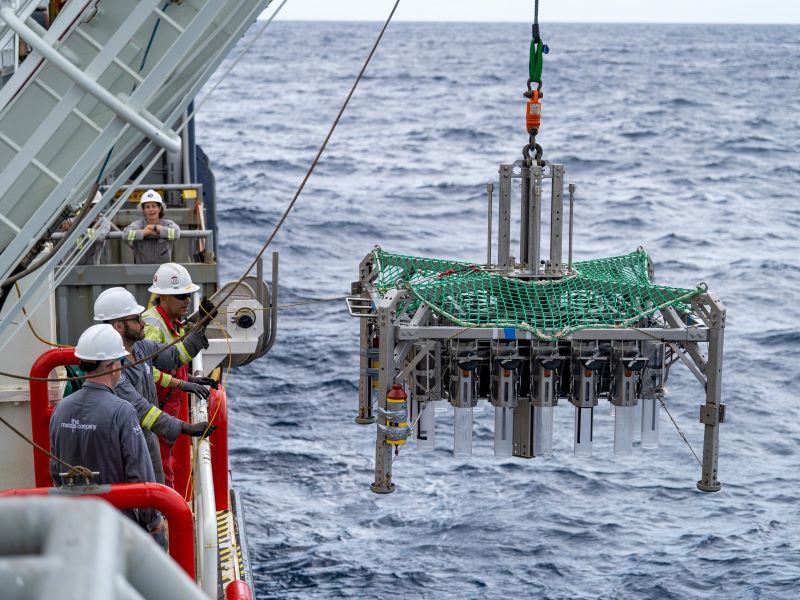

The collectors will use seawater nozzles to lift nodules from the seabed with minimal disturbance, avoiding drilling or blasting. The material will be separated from entrained sediment and excess water inside the collector and then moved through a 500m flexible jumper hose into the riser.

Compressed air injected at a depth of around 2,500m will help lift the nodules to the surface via a vertical transport system (VTS) and they will be stored in a production vessel’s hold before being offloaded to a transfer vessel.

On the production vessel, the nodules will be dewatered and stored, while residual seawater and sediment will be returned to the water column at roughly 2,000m.

The production vessel will work with the dynamically positioned transfer vessel so that nodules can be offloaded without interrupting seabed collection.

The transfer vessel would shuttle material to bulk carriers for shipment to shore, while support vessels would cover refuelling, waste handling and crew logistics.

The PFS assumes operations would begin with one collector deployed from the converted drill-ship, Hidden Gem, and then scale to two, supporting an initial target of 3mtpa of wet nodules.

After procedures have been optimised, and both operational and environmental monitoring confirm that nodule collection can be carried out to an acceptable standard, TMC anticipates designing and commissioning a second vessel, broadly comparable to the Hidden Gem.

As additional production vessels are deployed, output is expected to increase towards an average steady-state rate of around 10.8mtpa on a wet basis.

Ore processing at NORI-D polymetallic nodule project

The PFS assumes a rotary kiln-electric furnace technology to convert nodules into intermediate products including a nickel-copper-cobalt alloy and manganese silicate.

The alloy will be treated through sulfidation and converted to produce matte, which would then be refined using hydrometallurgical methods into copper cathode, nickel and cobalt sulphates, plus fertiliser-grade ammonium sulphate.

Onshore processing is expected to start under a five-year tolling agreement with Pacific Metals Company at Hachinohe in Japan, with capacity assumed at up to 1.3mtpa of wet nodules.

The study also envisages the construction of two dedicated refining facilities in the US to handle up to 12mtpa of wet nodules and upgrade intermediates into high-purity nickel and cobalt sulphates and copper cathode.

Infrastructure details

The CCZ can be reached by sea from a range of ports in the US and South America.

The CCZ deposit contains no habitable land and is not located near coastal waters. All personnel and equipment will be shipped to the project area.

There are no permanent facilities within the project area and all activities will depend on marine-based infrastructure.

Contractors involved

TMC appointed AMC Consultants to prepare the technical report summary for the PFS. Other companies involved are MARGIN – Marine Geoscience Innovation, APYS Subsea, Canadian Engineering Associates and Lanasera.

In March 2023, Bechtel was awarded a contract to gather and consolidate the techno-economic assessments prepared by NORI’s partners and contractors to underpin its application for an exploitation contract with the International Seabed Authority.