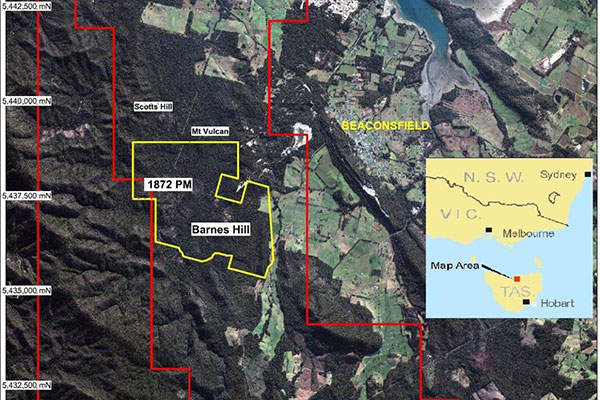

Barnes Hill nickel-cobalt mine is located in the Tamar Development Corridor and is situated near Beaconsfield in Tasmania, Australia. Proto Resource acquired the Barnes Hill run-of-mine nickel-cobalt project from Allegiance Mining in 2006. It aims at mining 500,000 tonnes per annum (tpa) of nickel and cobalt from the mine.

Barnes Hill will be an open cut mine that will produce 4,800t of nickel equivalent per annum. It is expected to have a mine life of 16 years.

Proto Resources signed a joint venture with Nickel Developments, a subsidiary of Metals Finance, for the mine’s development in 2007.

The mining lease was granted in June 2011 and construction started in 2012. Optimised feasibility study completed in March 2013 and the mining activities are expected to begin later in 2013.

Barnes Hill mine geology

Barnes Hill is a part of Anderson’s Creek Ultramafic Complex (ACUC). ACUC is a layered rock formation made up of Cambrian mafic and ultramafic stratigraphy containing serpentinite, pyroxenite, and gabbro rock formations.

The upper zone of the area contains secondary iron oxides like goethite, hematite and limonite, while the clay rich lower zone contains huge deposits of serpentinite, chlorite and smectite.

Both the zones are rich in secondary lateritic nickel, primary nickel sulphides and iron ore deposits.

Barnes Hill reserves

The probable reserves at Barnes Hill total 2.6 million tonnes graded at an average of 0.70% Ni. The combined measured and indicated resources have been estimated at 4.5 million tonnes graded at 0.50% Ni.

Mining and ore processing at Barnes Hill

Related project

Forrestania Nickel Project, Australia

The Forrestania Nickel Project is located 400km east of Perth, in Western Australia.

The run-of-mine project extends over 43.2ha and will mine up to a depth of 30m. It will extract 250,000t of nickel and cobalt ore per annum. The extracted ore will be crushed within the pit using an onsite crusher, and will be transported to the ROM stockpile area for separation.

Extraction of nickel at Barnes Hill will be carried out using vat leaching method and ion cxchange (IX) techniques.

The ore will be leached through a series of vats using sulphuric acid, forming a pregnant liquor solution (PLS). The PLS will be passed over the ion exchange resins to extract only the nickel ions.

Concentrated sulphuric acid will then be passed over the nickel ions to obtain nickel sulphate solution. Electro-winning process will be applied on the nickel sulphate solution to extract pure nickel metal.

The vat leaching stage is expected to recover 85% of nickel, while the ion exchange stage recovers 98% of the same metal.

Financing for the Barnes Hill nickel project

Proto Resources and Nickel Developments, a subsidiary of Metals Finance, are funding the Barnes Hill nickel laterite deposit on a 50-50 joint-venture (JV) basis.

Under the JV, Metals Finance will invest in the project along with Proto Resources. The capital invested by Metals Finance will be paid back first when the project begins commercial production.

Caterpillar Financial will provide $38m for the project under an agreement with Proto Resources.

The surplus profit from operations will be equally shared between NDL and Proto Resources after full repayment of the capital.

Contractors involved with Barnes Hill nickel-cobalt project

Caterpillar will supply the mining equipment to the Tasmanian mine as part of an agreement signed in August 2011.

Future developments at Barnes Hill mine

Proto Resources is planning to extract iron ore from the resultant waste at the Barnes Hill processing plant. The ore will be extracted using Barrier Bay technology on pregnant liquid solution (PLS) resulting from the leaching of sulphuric acid and nickel laterite ore.

Iron and magnesium will be separated from the solution using electrochemical process.

A six-month pilot project initiated in 2012 to determine the benefits of iron extraction using Barrier Bay technology resulted in a positive outcome.

The extracted iron will either be sold to Temco, a magnesium smelter located 25km to the mine site, or will be shipped to China.