The Josemaria copper-gold project is a high-grade copper-gold porphyry project being developed by Josemaria Resources (formerly NGEx Resources) in San Juan Province, Argentina.

Canadian company Lundin Mining signed a definitive agreement to acquire Josemaria Resources for an equity value of approximately C$625m ($485m) in December 2021. The transaction will give Lundin 100% ownership of the Josemaria copper-gold project.

The preliminary economic assessment (PEA) of the project was completed in January 2016 while the pre-feasibility study (PFS) was completed in November 2018. A feasibility study (FS) for the project was completed in October 2020.

The project is anticipated to produce more than 5.4 billion pounds of copper and 4.6 million ounces (Moz) of gold during its anticipated mine life of 19 years. The project development is estimated to involve a total initial capital investment of approximately $3.09bn.

The environmental social impact assessment (ESIA) for the project was submitted to the authorities in February 2021. The ESIA evaluation process is expected to be completed in the first half (H1) of 2022 while the basic engineering works of the project are anticipated to be completed in the second quarter (Q2) of 2022. The potential start of production is expected in 2026.

Josemaria copper-gold project location, geology, and mineralisation

The Josemaria copper-gold project is located approximately 10km from the Chilean border and 140km from Copiapo, Chile. The deposit remains open to the south and is hosted under a thick cover of post-mineral volcanic rocks.

The copper-gold mineralisation at the mine is hosted within a Miocene porphyry system, which is estimated to have formed approximately 24.7 million years ago. It features copper and gold mineralisation associated with the upper parts of the potassic alteration zone.

The copper-gold project hosts chalcopyrite and pyrite plus minor bornite through the potassic zone, while quartz–magnetite and chalcopyrite veining is also identified within the main mineralised zone.

Josemaria reserves

The proven and probable mineral reserves at the Josemaria copper-gold project were estimated at 1,012 million tonnes (Mt), grading 0.3% copper and 0.94g/t silver, and 0.22g/t gold, as of September 2020.

The contained copper, silver, and gold are estimated to be 6,705 million pounds (Mlb), 30.72Moz, and 7.02Moz, respectively.

Mining and ore processing at Josemaria copper-gold project

Conventional open-pit mining method, involving drilling and blasting followed by loading and hauling by autonomous trucks, will be employed at the Josemaria copper-gold project.

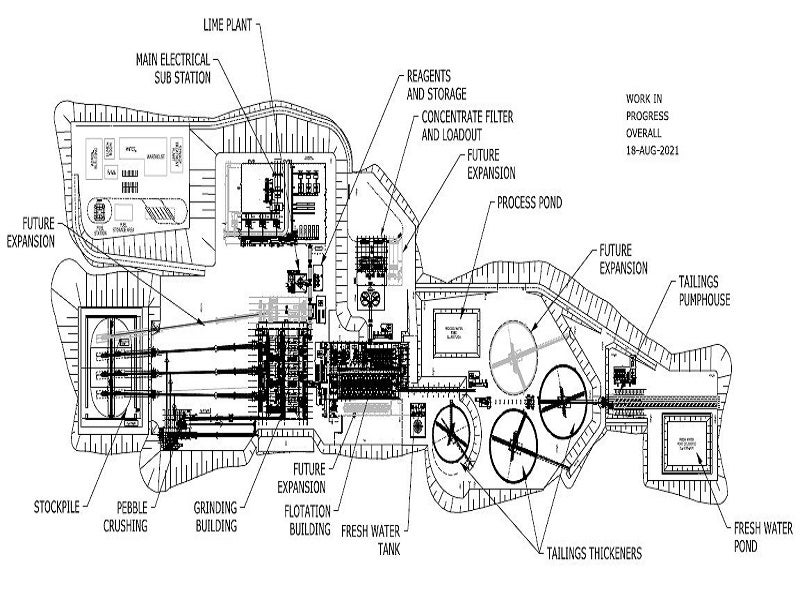

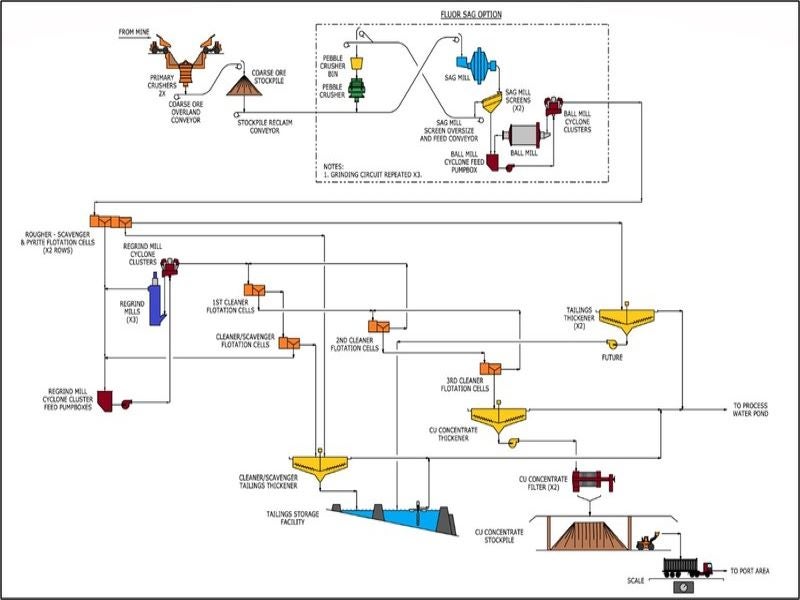

The processing plant is expected to treat ore at a nominal rate of 150,000 tonnes per day (tpd) of sulphide ore at the 75th percentile hardness while softer ores will be treated at up to 160,000tpd. Ore from the open pit will undergo crushing in Metso Mark III primary gyratory crushers.

The fine crushed product will be fed to three identical semi-autogenous grinding (SAG) mills, including a cyclone cluster and a ball mill. Discharge from the ball mill will be sent to the cyclone cluster, with the cyclone underflow flowing to the ball mills and overflow reporting to the rougher flotation section.

The conventional flotation process will include rougher scavenger flotation, regrinding, and three stages of cleaner flotation to produce a final copper concentrate. The concentrate will then be thickened with flocculant in a high-rate thickener and fed to the agitated copper filtration stock tank.

The final concentrates will be loaded onto concentrate trucks and transported to the port of Caldera in Chile for shipping to customers.

Infrastructure facilities at Josemaria

The project site will be connected to the Argentina Ruta Nacional 76 highway through a 57km-long access road, which will be upgraded.

Power required by the project is proposed to be supplied by a 250km-long, 220kV transmission line from the Guanizuil substation, which will be upgraded to facilitate the new interconnection.

Water for the mining operations is proposed to be collected from groundwater wells and nearby aquifers. Groundwater will be pumped from the wells and stored in an intermediate freshwater holding tank for supply to process facility, fire, camp water treatment, and other facilities.

Construction and operational staff will be accommodated at the accommodation camp, to be situated approximately 2.5km from the open pit.

Tailings generated at the plant will be stored in a typical surface storage facility.

Contractors involved in Josemaria mine

SRK Consulting (Canada) prepared the PFS of the project in Argentina. Other consultants who participated in PFS preparation included Ausenco Engineering, Knight Piésold, BGC Engineering, Merlin Geosciences, and Gino Zandonai.

Engineering and construction services provider Fluor Canada led the team that prepared the feasibility study. SRK Consulting (Canada) and Knight Piésold prepared certain key sections of the study. Multinational engineering, procurement, construction management company Ausenco was engaged to prepare 3D animations for the project.