IntelliSense.io, a specialist in Industrial AI for mining process optimization, won the Innovation award in the 2025 Mining Technology Excellence Awards for delivering quantifiable performance gains in live operations.

The Mining Technology Excellence Awards honor the most significant achievements and innovations in the global mining industry. Powered by GlobalData’s business intelligence, the Awards recognize the people and companies leading positive change and shaping the industry’s future.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

IntelliSense.io’s Scientific AI models—combining physics‑informed digital twins, machine learning, and advanced material tracking—have delivered measurable, real‑time improvements in production, recovery, and cost control across multiple mining processes and live operations.

Real-time AI control delivers quantifiable value and risk reduction

The company’s documented, site-level outcomes show material operational impact of its platform and edge AI products: brains.app, and brains.edge respectively. For example, in flotation process optimisation to increase recovery, IntelliSense.io combined digital twin models of CFD, Kinetic models with machine learning and virtual sensors providing real-time visibility into cell performance—including factors such as bubble size and gas holdup—and optimized set points like Air flow and Reagent dosage, enabling proactive setpoint adjustments and steadier operation. Reported outcomes at a large South American copper operation with complex circuits of more than 120 cells of multiple cell types include a 1–3% improvement in metal recovery, translating to an additional ~$5.5M per month in production value.

For thickening, the exposure of new variables, such as bed pressure, rake torque, and clear water height, which were previously hard to monitor in real time, helped operators take informed action. Predefined alerts were triggered up to 15 hours in advance of high‑torque stoppages, enabling timely intervention and preventing unplanned downtime. Reported results include prevention of stoppages tied to roughly $1.8 million in opportunity cost from non‑processed copper; potential recovery of approximately 22,000m³ of water; and avoidance of around $10 million in maintenance costs associated with a major tank event. The thickener example typifies the approach: anticipate disruptions, maintain stability, and protect both production and assets.

The same logic extends to other circuits. In grinding, role‑specific recommendations and virtual sensors that track mill charge, slurry density, and wear profiles supported a 1% increase in ore throughput and about $1.3 million in annual value, while helping avoid unplanned downtime due to liner changes. IntelliSense.io has also deployed integrated AI solutions with an Australian gold miner, successfully connecting mine and plant operations spanning its Run-of-mine and Crushed Ore Stockpiles, Flotation, and Leaching processes. The initiative aims to increase overall gold production and is set to deliver $12M in incremental benefits. Across these cases, value was unlocked without major capex, and implementations commonly moved from discovery to live operation in four to six months—reinforcing repeatability and risk reduction.

AI agents and digital twins enable proactive, autonomous operations

A common theme across the deployments is the use of objective‑driven AI agents that blend physics‑based process understanding with machine learning. Rather than offering static dashboards or Generative AI systems with a propensity to hallucinate, the IntelliSense.io system combines all these approaches with an ability to predict likely future states, recommend setpoints, and, where integrated in a closed loop, can automate control with defined safeguards. This is particularly relevant in plants facing variable feed and shift‑to‑shift operating styles. By standardizing to best‑known operating envelopes based on the ore feed coming through and adjusting in real time, sites reported more consistent underflow density and overflow clarity in thickeners, reduced reliance on flocculant to compensate for variability, and steadier recoveries in flotation and leaching.

Information is delivered in practical, role‑specific formats. Operators receive actionable setpoints and alerts; metallurgists and engineers see diagnostic context—helping teams move from reactive troubleshooting to proactive and predictive management. Virtual sensors fill gaps where direct measurement is impractical, such as predicting overloads or tracking hidden states inside mills and cells. Evidence from customer references shows progression from pilots to multi‑site rollouts at major miners across copper, gold, iron, and phosphates. One large mineral producer recorded an 18% reduction in process disruptions, illustrating how the approach improves day‑to‑day stability as well as headline metrics like recovery and throughput.

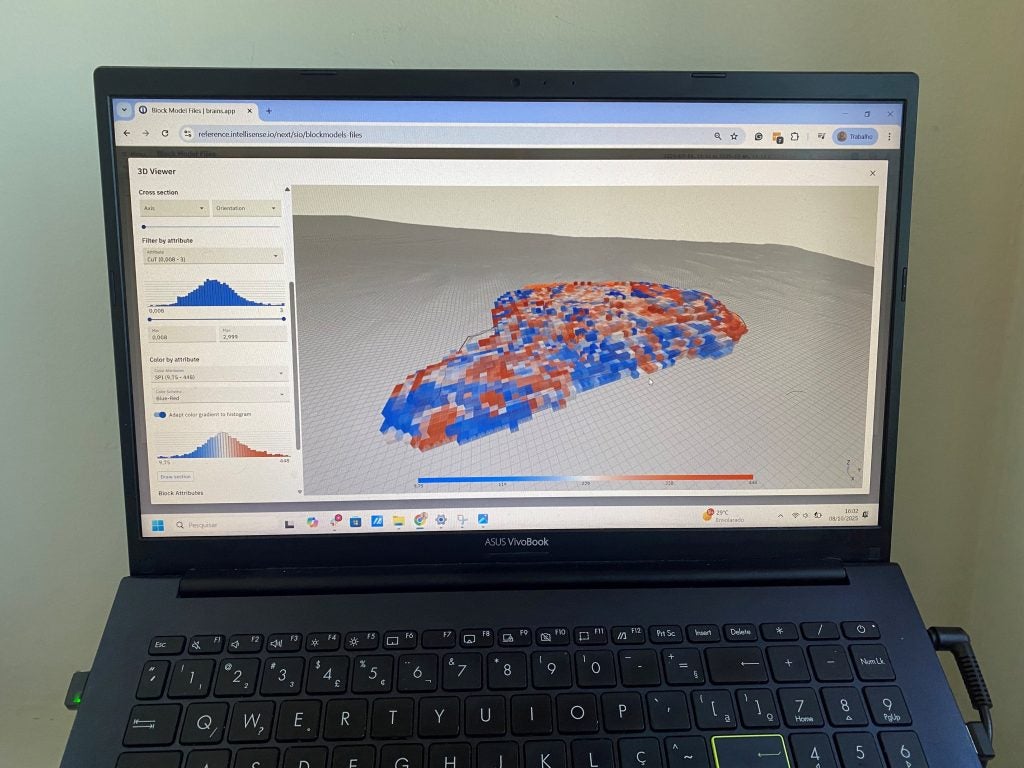

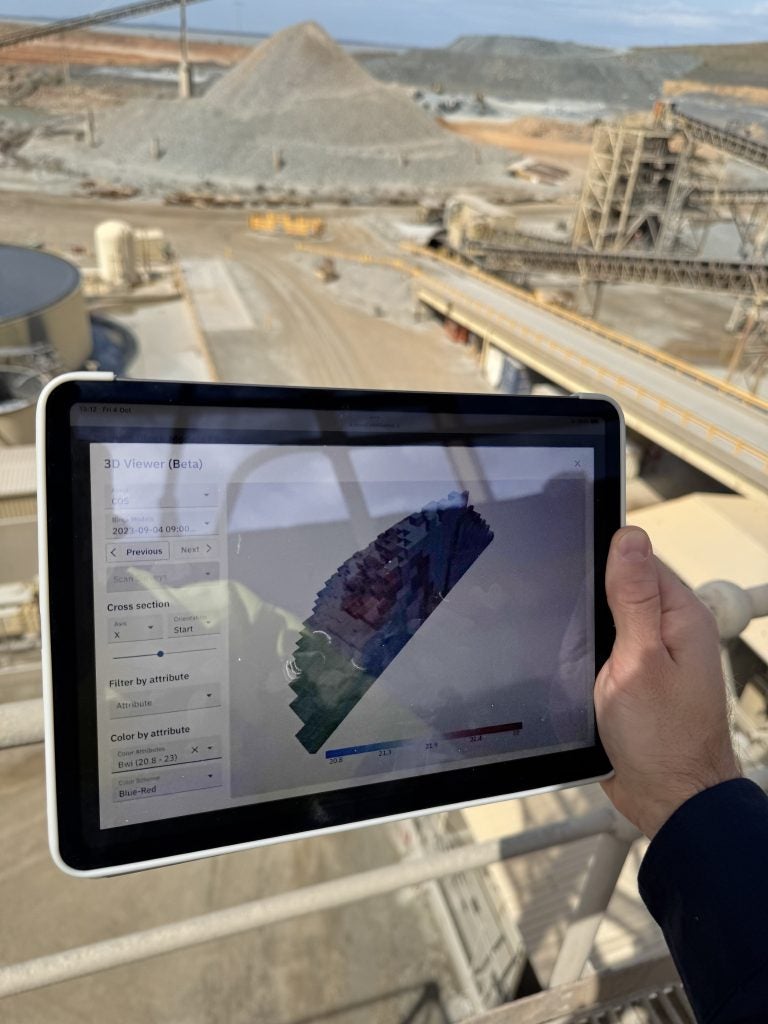

3D stockpile models and material flow models improve planning and feed to reduce plant variability

IntelliSense.io’s Geometallurgical intelligence systems with material tracking and 3D stockpile models connect mine and plant in practical ways. The Stockpile & Inventory Optimization (SIO) solution ingests fleet management and grade control data to build dynamic 3D block models of stockpiles—preserving material heterogeneity and the true provenance of what’s inside each pile.. The increased fidelity and higher granularity enable targeted reclaim and more precise blending—capabilities that are difficult to achieve with weighted‑average methods.

At a large gold mining operation in Australia, the 3D models helped the team identify higher‑grade zones within large, mixed ROM stockpiles and execute selective reclaim campaigns. From December 2023 to February 2024, the site reclaimed about 400,000 tonnes from modeled stockpiles, lifting average plant feed grade from 0.80g/t to 0.84g/t and bringing ounces forward, with more than AUD$2 million in additional value attributed to these campaigns. The site also used the models to prioritize specific areas for reclamation, improving feed quality against plan. Beyond the headline figures, the approach reduced time spent investigating discrepancies between expected and measured grades, improved collaboration between geology and metallurgy teams, and provided a clearer basis for weekly planning and reconciliation.

Other sites reported a 5–8% decrease in plant feed variability and over $1.4 million in annual value from stockpile modeling, as well as faster reconciliation. By linking material attributes—such as grade, hardness, and particle size—in real-time to downstream performance, operations can adjust plant setpoints with a clear view of what is coming into the circuit. That connection helps avoid deleterious events, supports reagent and acid savings in leaching and SX, and stabilizes grinding and flotation performance. Together, the SIO solution, coupled with tracking capabilities, gives mines a practical lever to optimize feed quality and plan proactively, not reactively.

Scalable delivery and sustainability impact

IntelliSense.io reports deployments across eight countries, supporting nine of the top 20 mining companies. A managed software service model, rapid implementation, and continuous calibration underpin sustained value realization, with a typical value return of 10x and documented improvements such as the 1-3% increase in metal recovery from flotation optimization noted above for one producer. The platform also supports sustainability objectives by optimizing water reuse, reducing reagent and acid consumption, and lowering energy intensity while maintaining or increasing production.

“The Mining Technology Award is a great recognition of the work the team has been doing with our customers in partnership across a range of commodities in the Mining & Metals industry, demonstrating the operational value of embedding AI in real-world operations across the Mining value chain. By incorporating the technological advances in the field of AI with industry-specific domain knowledge, we have built an industrial digital twin portfolio of objective-driven AI models that power our clients’ operations—from project development and CAPEX programs to the continuous optimization of existing operations.”

– Sam G. Bose, Founder & CEO, IntelliSense.io

Company Profile

IntelliSense.io enables global minerals and metals infrastructure owners to discover, automate, and monetize optimization opportunities that were previously considered too complex—or even impossible—to achieve on a continuous basis.

As an Industrial AI company, IntelliSense.io deploys our real-time decision-making platform, brains.app, and a suite of process-specific optimization applications to address the complex variability challenges in mining. They give customers a precise understanding of what is happening in their processes right now, predict what will happen next, and enable them to act in choosing and optimizing their desired future state.

Using a system of AI agents with human-like planning and reasoning capabilities, integrated with domain-specific proprietary data models, we have demonstrated AI as a “system of action” that enables mining operations to become autonomous. These agents make high-value decisions, execute tasks, and augment human capabilities, allowing industrial operations to run more safely, efficiently, and sustainably.

With deployments across the top 20 major miners’ operations worldwide, IntelliSense.io has active sites in North America, Latin America, Australia, the Middle East, and Africa. Headquartered in Cambridge, UK, our solutions deliver efficiency gains across the entire mining value chain, enhancing operations on a truly global scale.

Contact Details

Tim Knight

Chief Marketing Officer, IntelliSense.io

Email: tim.knight@intellisense.io

Phone: +44 7798 735120

Links

Website: https://www.intellisense.io/