Schauenburg Systems, an Original Equipment Manufacturer (OEM) for mining and industrial markets, has won Innovation and Safety awards in the 2025 Mining Technology Excellence Awards for its ProXYmus Collision Prevention System (CPS). As mining operations increasingly prioritize operational efficiency and safety compliance, these awards highlight the company’s approach to addressing critical safety and productivity challenges through advanced technology.

The Mining Technology Excellence Awards honor the most significant achievements and innovations in the mining industry. Powered by GlobalData’s business intelligence, the Awards recognize the people and companies leading change and shaping the future of the industry.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

Schauenburg Systems won the Innovation award in the Collision Prevention Systems category for its development of the ProXYmus Collision Prevention System, recognized for advancing accident prevention and operational efficiency in mining environments. The company also received the Safety award in the Connected Safety category for its comprehensive approach to workforce protection, leveraging real-time monitoring and automated safety measures to enhance personnel safety across mining operations.

Collision prevention technology: ProXYmus CPS sets new standards

Scheduled for launch in 2025, the ProXYmus CPS introduces advanced sensing technologies, predictive analytics, and IoT integration to enhance accident prevention in mining environments.

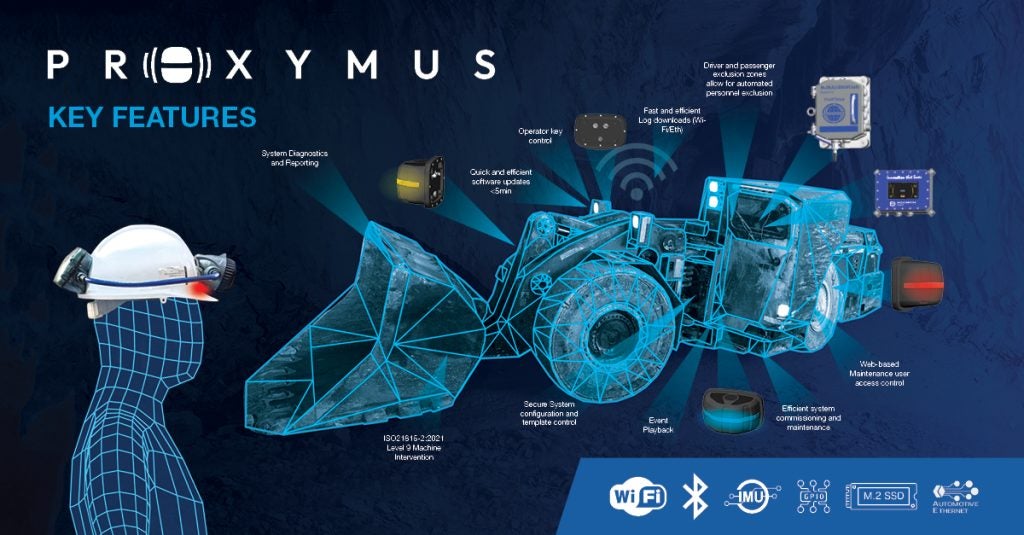

A key factor in the award recognition is ProXYmus’s Level 9 collision prevention capability, which leverages a combination of multiple sensing and ranging technologies, such as high-precision Angle of Arrival (AoA) sensors and predictive analytics. This multi-layered approach enables the system to achieve high-accuracy detection and intervention, preventing potential accidents before they occur. For example, ProXYmus can dynamically shape detection zones around vehicles and equipment, adapting in real time to operational changes and environmental conditions. This ensures that both vehicle-to-vehicle and vehicle-to-pedestrian interactions are managed proactively, reducing the likelihood of incidents in high-traffic or confined mining areas.

The system’s predictive situational awareness is further enhanced by its ability to perform real-time path and collision prediction. Unlike conventional systems that rely solely on machine telemetry, ProXYmus can analyze movement patterns and predict possible collision scenarios, allowing for timely automated interventions such as slowing or stopping vehicles. This not only improves safety outcomes, but also optimizes operational workflows by reducing unnecessary stoppages and maintaining productivity.

Another significant innovation is the system’s ability to minimize false alarms through advanced detection algorithms. By filtering out nuisance alarms and focusing on critical alerts, ProXYmus helps operators maintain focus and respond effectively to genuine hazards. This feature is particularly valuable in congested mining environments, where excessive false alarms can lead to alert fatigue and reduced vigilance.

ProXYmus is designed with a modular and scalable architecture, featuring a motherboard-daughterboard structure that supports future expansion and integration of emerging technologies. Its interoperability with third-party platforms—including fleet management systems, autonomous vehicle controls, and environmental monitoring solutions—ensures flexibility in deployment and future-proofs the investment for clients.

The integration with the Schauenburg SmartMine IoT platform is another key differentiator. This connectivity enables continuous data streaming, local processing, and comprehensive analytics, supporting predictive maintenance and long-term trend analysis. For example, mines can use the system’s data insights to identify recurring risk patterns, optimize traffic flows, and schedule maintenance proactively, reducing unplanned downtime and improving asset utilization.

User experience is also prioritized through a high-resolution touchscreen interface, intuitive controls, and voice alert integration. Automated test stations for vehicles and personnel ensure continuous system validation and compliance with safety standards, while remote software updates and diagnostics streamline maintenance and minimize operational disruption. Compliance with ISO21815-2:2021 (Level 9 Machine Intervention) further demonstrates the system’s alignment with industry best practices and regulatory requirements.

Connected safety solutions: Enhancing workforce protection

The Safety award recognizes Schauenburg Systems’ comprehensive approach to workforce protection in mining operations. The ProXYmus CPS integrates automated exclusion zones, real-time monitoring, and environmental interlocks to enhance safety for both drivers and passengers.

A central aspect of the system’s connected safety capabilities is its use of advanced Angle of Arrival (AoA) technology, which consolidates multiple sensor readings to provide precise distance, angle, and movement tracking of both people and machinery. This enables the creation of highly accurate exclusion zones, such as driver and passenger exclusion areas, which are automatically enforced by the system. For example, if a pedestrian enters a designated predetermined exclusion zone, ProXYmus will automatically exclude the pedestrian as either a Trackless Mobile Machine (TMM) operator or TMM passenger. This reduces the need for additional acknowledgements.

The system’s situational awareness zones are highly configurable, allowing operators to define complex, irregularly shaped zones that reflect the unique layout and operational requirements of each TMM site. The three configurable zones include a Level 7 warning zone, Level 8 advisory crawl and stop zones, as well as Level 9 automated stop and crawl zones. This level of precision and flexibility ensures that safety measures are tailored to the specific risks present in different areas of the mine.

ProXYmus’s integration with the SmartMine IoT platform supports continuous monitoring and automated diagnostics, enabling rapid identification and resolution of issues that might arise. Remote software updates can be completed in under five minutes per vehicle, minimizing downtime and ensuring that the latest safety features and compliance requirements are always in place. Automated test stations for both vehicles and personnel provide ongoing functionality validation, helping mines maintain compliance with internal safety protocols and external regulations.

The system also incorporates gas interlocking and environmental monitoring capabilities, allowing it react to unsafe mining environments. For example, if hazardous gas levels are detected, ProXYmus can automatically halt vehicle operations to protect personnel. This integration of environmental data with collision prevention measures provides a holistic approach to site safety.

Ruggedized hardware ensures reliable performance in harsh mining conditions. ProXYmus features an IP67 dust and water resistance rating, wide operating temperature range, and mining-grade shock and vibration resistance to ensure the system’s reliability for every mining condition. The system’s cost-effective design, ease of installation, and low cost of ownership contribute to long-term value by reducing operational risks, improving asset utilization, and supporting regulatory compliance.

By combining real-time tracking, automated interventions, and comprehensive data analytics, ProXYmus enables mining operators to proactively manage safety risks and protect their workforce in dynamic and challenging environments.

“Winning these awards for Innovation and Safety reinforces our commitment to advancing intelligent solutions that protect lives and empower mining operations. With ProXYmus, we are redefining what’s possible in underground safety—merging precision technology with real-world impact. At Schauenburg Systems, innovation is not just our focus, it’s our responsibility.”

– Dieter Kovar, CEO of Schauenburg International – Africa Group

Company Profile

Schauenburg Systems is an Original Equipment Manufacturer with branches all over South Africa. It is part of the Schauenburg International Group, a strategic family equity investor headquartered in Germany. Schauenburg Systems provides technology solutions for enhanced safety and productivity in mining and industrial markets. By pooling vast internal engineering expertise and access to external competence, it lives up to its brand promise of “Innovation that Saves”. It has positioned itself as an active partner for digital transformation like for the upcoming requirements of the “Connected Worker”.

Contact Details

Links

Website: www.schauenburg.co.za

Learn more about Schauenburg Systems‘ Collision Avoidance Solutions: https://schauenburg.co.za/products/collision-avoidance-systems/