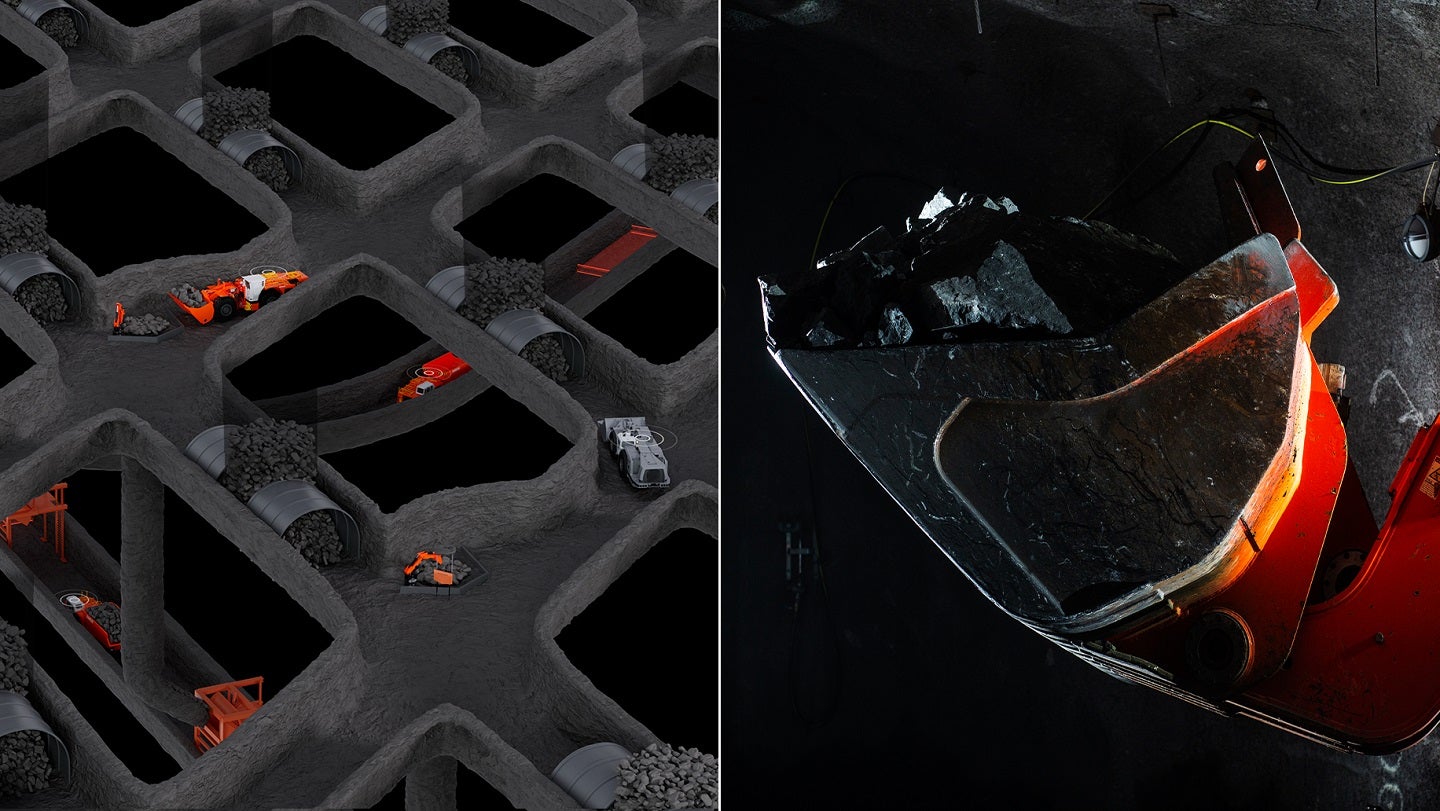

Sandvik Mining and Rock Solutions has unveiled a comprehensive automation platform, AutoMine Core, for large-scale mining operations.

The new system is designed to help customers transition from manual mining techniques to fully automated production processes.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

It offers users a range of compatibility options for Sandvik’s own fleet and third-party original equipment manufacturer fleets.

Leveraging Sandvik’s AutoMine Fleet and manual production monitoring solutions, the AutoMine Core platform provides access to technologies for underground connectivity, data aggregation and analysis, and several automated equipment choices.

Its implementation is expected to enhance safety, sustainability and productivity for underground mining.

Sandvik Mining and Rock Solutions product line and customer projects automation acting director Ty Osborne said: “AutoMine is used in more than 100 mines globally, including more than 20 mass mining applications.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalData“AutoMine Core combines advanced planning and scheduling capability with top-tier underground autonomy, integrating seamlessly into a mine’s digital ecosystem. This integration enables our customers to achieve end-to-end optimisation, resulting in increased productivity and added value.”

Furthermore, the AutoMine Core platform offers solutions that provide insights to help customers optimise operational safety and productivity.

Sandvik said that by harnessing its AutoMine Fleet traffic management, the AutoMine Core platform will facilitate easy control over traffic flow in multi-machine operations.

It also allows customers to handle complex situations such as advanced deadlock control, dynamic dispatch and dynamic speed scaling.

Osborne added: “We believe this platform will transform mass mining operations, helping maximise safety, productivity and sustainability.”