Australia-based mineral exploration company Arafura Resources is developing the Nolans neodymium-praseodymium (NdPr) project, which is located approximately 135km north of Alice Springs, Northern Territory (NT).

Arafura acquired the licence for the open-cut mine in 2001 and is currently undertaking a seven-phase pilot programme to validate the process flowsheet. The mine received major project status from the NT government in 2014 and was also awarded major project facilitation status by the Australian Government in September 2016. The status will enable Arafura to accelerate the development of the project.

With an estimated capital cost of $680m, the project is capable of supplying up to 10% of the world’s demand for rare earths (RE) used in magnets.

Feasibility study of the RE project is expected to be completed by the end of 2018, with production slated to commence in 2019. The project is expected to have a mine life of more than 20 years. It is currently in final stages of securing environmental approval.

The mine is expected to produce 14,000 tonnes per annum (tpa) of total rare earth oxides (TREO) and 110,000tpa of merchant-grade phosphoric acid as a by-product.

Nolans RE project location, geology and mineralisation

The project falls within three granted exploration licences (ELs), specifically EL28473, EL28498 and EL29509, and is in close proximity to the Stuart Highway, Adelaide, to Darwin railway, Amadeus gas pipeline, and a large source of underground water.

The Nolans Bore deposit, the project’s centrepiece asset is one of the biggest and most vigorously explored deposits of its kind in the world. The deposit hosts the most abundant RE-bearing minerals such as apatite, monazite and allanite.

The project hosts two broad styles of RE-bearing mineralisation namely apatite and calcsilicate. The apatite mineralisation comprises approximately 95% fluorapatite, along with RE-bearing minerals such as monazite group minerals, allanite and thorite, as well as other RE phosphates, including silicates and carbonates.

The calcsilicate mineralisation of a lower grade than apatite mineralisation mainly comprises apatite, allanite, epidote, amphibole and pyroxene. It also consists of high concentrations of calcium, phosphorous, thorium, uranium, strontium and fluorine apart from REs.

Mineral reserves at Nolans

The JORC 2012-compliant mineral resources of Nolans NdPr project are estimated at 56 million tonnes (Mt), containing 382,000t of NdPr oxide grading at 2.6% TREO.

Mining and processing of ore at Nolans RE project

Conventional open-cut mining, comprising drill and blast, followed by load and haul, will be applied at the Nolans RE project.

The run-of-mine ore will be transferred to the primary crusher, followed by crushing in a comminution circuit. It will then pass through grinding, and beneficiation circuits to reject gangue and produce a mineral concentrate.

The concentrate will be transported to the processing plant through a single pumping stage slurry pipeline. It will then undergo chemical processing by using a phosphoric acid pre-leach process that leverages the phosphate-rich characteristics of the concentrate.

The resulting solid rare earth-bearing products will go through processes such as baking, water leach, precipitation and purification to produce NdPr-rich rare earth chloride intermediate product and a cerium oxide product.

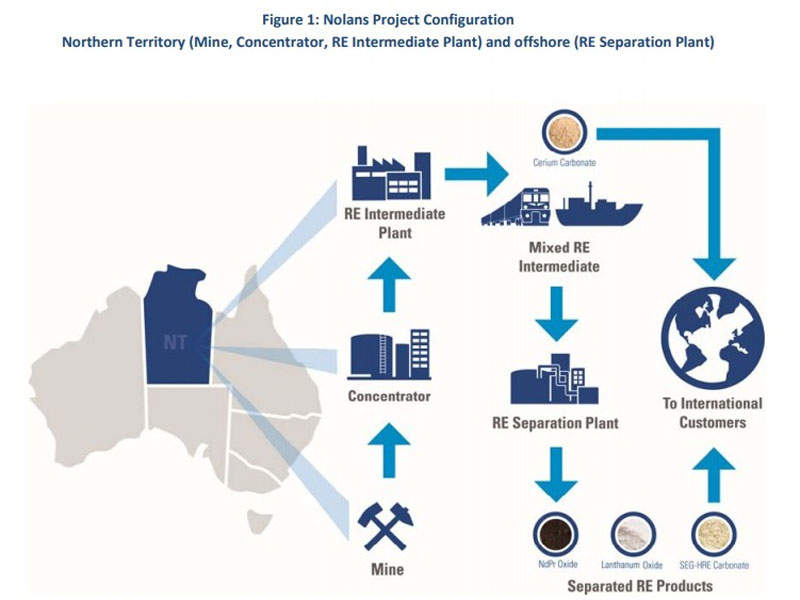

An estimated 15,000tpa of high-value RE intermediate product will be trucked to Alice Springs and transported to the Port of Darwin by rail. It will then be shipped to an offshore refinery for toll refining.

The REO production from the project is expected to include 3,600tpa of NdPr oxide, 2,660tpa of lanthanum oxide, 660tpa of mixed middle-heavy rare earth (SEG-HRE) carbonate, and 7,100tpa of cerium hydroxide.

Details of the Nolans pilot programme

The Nolans pilot programme will validate the process flowsheet of the mine and its data will be added to the definitive feasibility study. Ore will undergo beneficiation, phosphate extraction, bulk pre-leach, acid bake, RE purification and precipitation, RE dissolution and crystallisation, and separation processes as part of the seven-phase pilot programme.

The trials on NdPr-rich pre-leach residue feedstock from the phase two phosphate extraction pilot plant resulted in 98.5% extraction of light REs to sulphated (acid-baked) material.

Arafura concluded the first stage of the four-phase piloting in October 2017 and anticipates completing the phase four acid bake pilot plant construction during the first half of May 2018. It also plans to commence the fifth and sixth phases immediately after phase four.

Arafura, along with SGS Australia and Curtin University, has agreed to produce synthetic inert materials resembling the acid bake feed and sulphated material produced during the October trials at Nolans.

Infrastructure facilities at Nolans

Power supply for the RE project will be made through a gas-fired power plant, supplemented by steam-generated power from a sulphuric acid plant.

Piping water required by the project will be collected from borefields south-west of the mine.

Workers will be accommodated at a 300-person accommodation village near the mine.

Contractors involved

Hatch was awarded the contract for preparing the definitive feasibility study of the project.

Arafura collaborated with Korean chemical manufacturer OCI to determine a suitable site for a downstream separation (refining) plant, thereby reducing processing and transportation costs.

SNC-Lavalin, Prayon Technologies, and ANDRITZ Gouda are providing independent expert advice and supervising all the phases of the Nolans pilot programme.

Bossong Engineering was engaged to undertake the works at pug mixer construction unit as part of the phase four pilot programme.