The Admiral Bay underground zinc mine is located in the Canning basin of Western Australia. The project is being developed by Australian mining and exploration company, Metalicity.

Pre-feasibility study (PFS) for the Admiral Bay deposit is being conducted in two stages. Metalicity completed stage one of the pre-feasibility study (PFS) in July 2016, while stage two is currently in progress.

With an estimated mine life of 20 years, the project will support low-cost zinc, lead and silver operations.

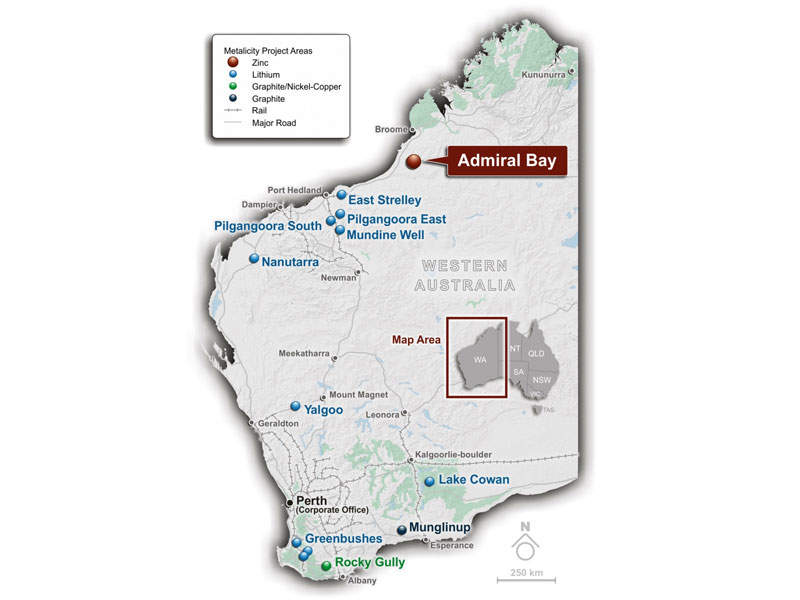

Admiral Bay zinc project location, geology and mineralisation

The mine is located in the Canning Basin of the Kimberley region, 140km south of Broome, Western Australia.

Admiral Bay is a Mississippi Valley Type (MVT) deposit with an 18km mineralised corridor along the Admiral Bay fault zone. The mineralisation occurs in shallow water limestones on a fault-controlled palaeohigh and includes two zones – an upper zinc-rich zone and a lower lead-rich zone.

The upper zone is 20m-thick and the mineralisation is hosted in the Cudalgarra group of the Nita Formation and the Ordovician Bongabinni formation of the Caribuddy Group. The lower zone is 15m-thick and is of the Goldwyer Formation.

Mining and processing at Admiral Bay

Open stoping with backfill and longwall mining methods is proposed to be applied at the underground mine. One of the three shaft sinking techniques including traditional decline development, tunnel bored machine decline development, and vertical shaft sinking will be selected for the project.

Ore processing will take place through a simple and conventional float processing plant to achieve higher grades of zinc, lead and silver recoveries. The ore processing will involve two-stage crushing, two-stage grinding and thickening process to produce zinc and lead concentrates.

Admiral Bay zinc project reserves

The Admiral Bay project is estimated to hold inferred mineral resources of 170 million tonnes (Mt) containing 7.5% of Zn-equivalents (4.1% Zn, 2.7% Pb, 25g/t Ag).

Offtake of zinc from Admiral Bay

Metalicity signed a memorandum of understanding (MoU) with China Minmetals Corp subsidiary Minmetals Nonferrous Metals (CMN) in July 2017 for the supply of 10% of zinc and lead offtake of the initial production from the Admiral Bay project.

The initial 10% offtake will be allocated to CMN in exchange for metallurgical and beneficiation test-work.

Infrastructure at Admiral Bay

The mine can be accessed from Great Northern Highway located approximately 80km west of the project area, along the McLarty track.

The lead and zinc concentrates will be transported in sealed containers by road from Great Northern Highway to Port Hedland, which is located 430km away from the Admiral Bay zinc deposit. Other port options available for the project area include Broome and Derby.

The power required for the project will be met through liquefied natural gas (LNG) generators, geothermal and tidal power sources. Water for the mining operations will be sourced from the Broome Sandstone aquifer, while material mine dewatering will be from lower aquifers.

A 500-member accommodation camp facility is also being planned for the workers at the project site.

Financing

Resource Capital Funds (RCF) has provided Metalicity with A$5m ($3.5m) to complete the scoping study for the project.

Contractors involved

RSV Australia was appointed by Kagara to prepare the pre-feasibility report on the zinc project.

Scoping study for the project was completed by technical consultant SRK Consulting, while conceptual ventilation assessment was conducted by BBE Consulting.

Metalicity appointed Optiro to prepare resource estimates of the project, while Perth-based engineering consultancy Mintrex is studying the project infrastructure requirements.