The Madsen gold project is located in the Red Lake district of northwestern Ontario, approximately 440km north-west of Thunder Bay, Ontario, Canada.

Considered to be one of the highest-grade, undeveloped gold projects in the world, the mine is anticipated to recover 911,497oz of gold.

Pure Gold Mining purchased the historic Madsen gold mine in 2014, which produced 2.5 million ounces (Moz) of gold at an average grade of 9.7g/t gold between 1938 and 1999.

Underground exploration and infill resource delineation drilling at the Canadian project commenced in July 2017. The preliminary economic assessment (PEA) of the project was completed in September 2017, while the definitive feasibility study (DFS) began in December 2017.

The DFS is scheduled to be completed by the third quarter of 2018.

Madsen gold project reserves

The Madsen gold project is estimated to contain indicated resources of 5.79Mt, containing 1.65Moz of gold grading 8.9g/t Au.

Inferred resources are estimated at 0.59Mt, grading 9.4g/t Au and containing 178,000oz of gold.

Madsen gold project location and geology

The Madsen gold project is located in the Red Lake greenstone belt, which is one of Canada’s biggest gold-producing districts known to have produced more than 28Moz of high-grade gold.

The greenstone belt occurs within the Uchi Subprovince of the Superior Province of the Canadian Precambrian Shield.

The mine is made up of a contiguous group of 258 mining leases, mining patents and unpatented mining claims spread over 4,769ha (47.7km²).

Gold mineralisation at Madsen

Mineralisation at the Madsen project is believed to have formed through the interchange of a series of cryptic, early structures with lithological contacts between basalt and ultramafic rocks of the Balmer Assemblage.

Replacement-style disseminated gold mineralisation is hosted in Balmer mafic volcanic rocks adjacent to ultramafic intrusive rock units. The gold mineralisation is highly centred within the high-grade Austin, South Austin, A3, and McVeigh deposits.

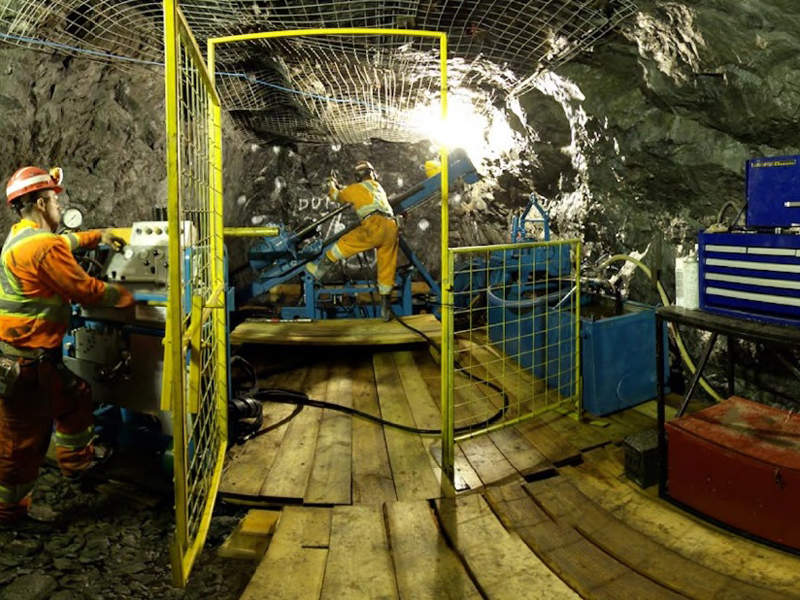

Mining and processing of ore at Madsen

Conventional and mechanised cut & fill mining method with limited application of shrinkage process is proposed to be used for extracting the ore at Madsen. Mining is proposed to be conducted using hand-held drills, while slushers will be used for mucking.

The processing plant at Madsen will have a capacity of 600t/d and feature a single-stage crushing circuit, a two-stage grinding circuit, and cyanide leaching unit. The project is anticipated to achieve a nominal production rate of 219,000 tonnes per annum (tpa).

Ore from the Madsen portal is proposed to be hauled and crushed in a portable crusher unit on the mill apron. The crushed material will then be taken to the semi-autogenous grinding (SAG) mill for grinding, via a feed conveyor, followed by a secondary ball mill.

The ground feed will be transported to a pre-leach thickener for water recovery, followed by cyanidation. The cyanidation circuit will consist of five agitated leach tanks, with the first tank being the pre-aeration tank and the other four tanks being used to convert the gold from solid form into a gold derivative in slurry.

The leached gold will be forwarded to the carbon-in-pulp (CIP) circuit containing six agitated tanks, where it will be recovered onto the surface of activated carbon particles.

Loaded carbon will be removed from the first tank and recovered in the strip circuit and forwarded to the electro-winning circuit to recover the gold in a marketable form. The recovered gold will be further refined to dore bars in an induction furnace.

Madsen underground mine infrastructure

Power supply for the gold mine will be provided by Hydro One Distribution from its 44kV/2,300V transformer station. The existing 2,300V power distribution system will be refurbished and a new transformer station will be constructed.

Diesel fuel will be stored in a double-walled 45,000l capacity reservoir, while gasoline will be stored in a 5,000l reservoir.

Process water required for the underground operations will be drawn directly from the nearby pond.

Construction at Madsen gold project

Pure Gold re-opened the Madsen underground mine portal in January 2017 and commissioned the site infrastructure facilities in February 2017.

The water line from the process pond to McVeigh ramp was commissioned in the same month, while the 800m-long power line from Madsen Mill to McVeigh Portal was commissioned in March 2017.

The ventilation and heating system of the underground mine was fitted in April 2017, while underground drilling works started in July 2017.

Contractors involved

Ginto Consulting provided the mineral resource estimates for the Madsen gold project.

JDS Energy and Mining (JDS) was contracted to prepare the DFS. The contractor will be supported by Nordmin Engineering, Knight Piésold and MineFill Services.