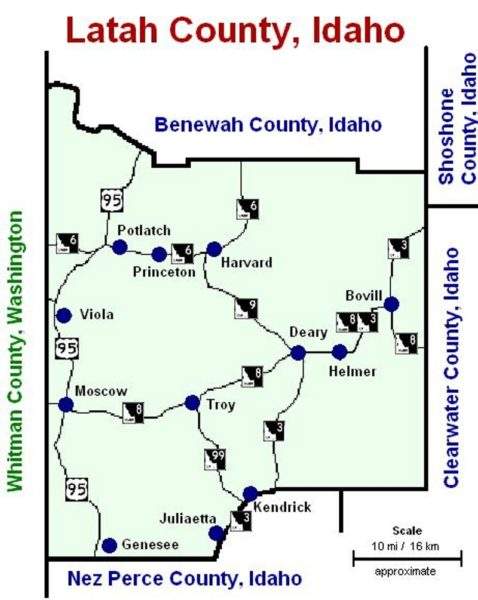

I-Minerals’ Bovill Kaolin Project, covering a total area of 5,140.6 acres, is located near the town of Bovill, in Latah County, Idaho, US.

The feasibility study (FS) for the project was completed in March 2016, which determined that the overall investment to bring the project into production would be $108.3m, and the mine would have a life of 27 years.

The project aims at extracting three potassium feldspar products, two halloysite products, and a metakaolin product, with an average annual production rate of 346,000t.

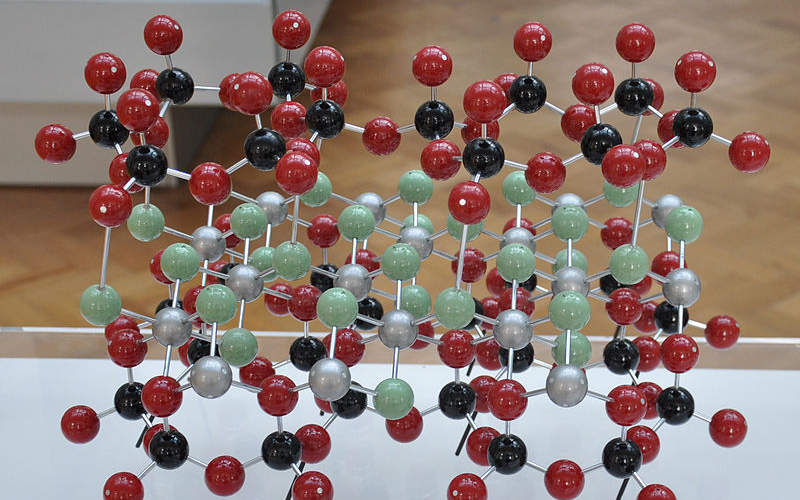

Bovill Kaolin project geology and mineralisation

The project area is primarily underlain by granitoid intrusive rocks of the Cretaceous age (145.5 and 65.5 million years ago), which form part of a body referred to as the Thatuna batholith.

The Thatuna batholith went through intense weathering during the Miocene epoch (23.03 to 5.3 million years ago), which altered most of the feldspar and some of the mica in the igneous body to one or more varieties of clay minerals.

The project hosts four types of deposits, namely the Na-feldspar deposits, residual K-feldspar-quartz-kaolinite-halloysite deposits, transported clay deposits, and K-feldspar-quartz tailings deposits.

The K-feldspar-quartz-kaolinite-halloysite deposits, which will be developed as part of the project, were derived from saprolitic weathering of the Thatuna granodiorite-granitic phases.

Reserves at the Idaho mine

As of October 2015, the project was estimated to hold combined proven and probable reserves of 8.072Mt grading 77.3% quartz & K-feldspar, 11.8% kaolinite and 4.4% halloysite, containing 6.725Mt of quartz & K-feldspar, 1.028Mt of kaolinite and 382,000t of halloysite.

The combined measured and indicated resources were estimated to be 21.26Mt grading 62.27% quartz & K-feldspar sand, 14.67% kaolinite and 3.14% halloysite, containing 13.235Mt of quartz & K-feldspar, 3.119Mt of kaolinite, and 667Kt of halloysite.

Mining and processing at I-Minerals’ flagship project

The mining method envisaged for the project is the open-pit mining method, integrating 30t trucks and excavator operations. The mining works will be performed by a contractor.

The proposed processing plant will primarily integrate a run-of-mine (ROM) stockpiling area, a crushing circuit, a clay/sand separation facility, a feldspathic sand circuit, to produce separate quartz and K-feldspar products, and a clay circuit to produce separate kaolinite and halloysite products.

Infrastructure for the Bovill Kaolin project

The electricity required for the project will be supplied by Avista Corp., from the national grid. The project will necessitate the installation of a two mile-long, 115kV line from the grid to a new substation, and a two mile-long, 24kV line from the substation to the plant site. An 800kVA generator will also be installed at the site for power back-up.

The natural gas required for the processing plant will be sourced from an existing natural gas pipeline that extends from Moscow to Bovill, via a new two-mile interconnection pipeline.

A small reservoir, located to the north of the project site, will meet the water requirements of the processing plant, whereas potable water will be sourced from wells drilled on-site.

No accommodation facilities will be required at the site, due to the availability of skilled labour force at nearby communities and rural areas.

Other major infrastructure at the site will include backfill dumps and two external waste dumps, fuel storage facilities, a water treatment plant, temporary haul roads, a number of buildings housing offices, a laboratory, workshop and warehouse, mess and shower facilities, packaging facilities, and security rooms.

Key players involved

GBM Engineers served as the lead consultant in conducting the feasibility study. Other sub-consultants involved in the study were HDR Engineering, who conducted the environmental, hydrology / hydrogeology and road design studies, Tetra Tech, who provided the tailing storage facility design, Mine Development Associates (MDA), who provided the mine modelling, ore scheduling and mineral reserve estimate, and SRK Consulting, who provided the mineral resource estimate.