The Lomas Bayas copper mine is in the Atacama Desert of north Chile in the San Cristobal mountains. The mine is at an elevation of 1,500m and lies approximately 110km northeast of the coastal port of Antofagasta. The mine has a workforce of around 390 people.

Developed by Westmin Resources Ltd, which spent some $244m on the property, Lomas Bayas was then bought by Boliden before being sold again, this time to Falconbridge, in mid-2001 for $175m. In mid-2006, Xstrata plc bought Falconbridge, with Lomas Bayas now being operated within its copper division.

Geology and reserves

The Lomas Bayas orebody is hosted by upper cretaceous volcanic-arc rocks and associated back-arc sediments, which are intruded by an upper cretaceous-paleocene composite granodiorite batholith.

The orebody is oxidised with a few zones of mixed oxide-sulphide. Copper mineralisation occurs in an irregular concentric zone around a low grade centre.

As of June 2008, proven reserves at Lomas Bayas I totalled 72.7Mt grading 0.36% copper and 0.21% soluble copper. Measured resources added up to 98Mt at 0.22% copper and 0.15% soluble copper. Inferred resources were 2.6Mt at 0.23% copper and 0.12% soluble copper.

Lomas Bayas II, as Fortuna de Cobre had been renamed, has a proven reserve base of 256Mt at 0.3% copper and 0.22% soluble copper. Measured resources stood at 273Mt at 0.31% copper and 0.22% soluble copper.

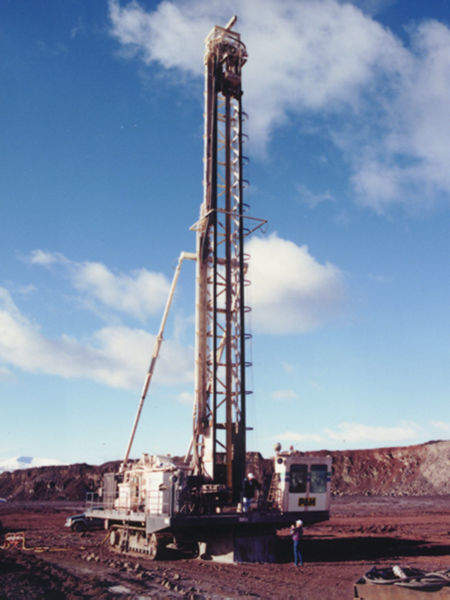

Open-pit mining

Lomas Bayas currently operates one open-pit mine. The orebody has been explored to a depth of 300m and consists of five main mineralised zones structurally controlled by faulting: the Tirana, Candelaria, Andacolla, East and Gordo zones.

Key items of open-pit equipment include a P&H 100XP blasthole rig and two P&H 2800XPB electric shovels. Heap-leach grade ore is crushed and placed on leach pads by a series of portable conveyors and a stacking system. Lower-grade, run-of-mine ore is placed directly on separate pads by mine haulage trucks.

The mine completed a crusher expansion programme in 2004, increasing its capacity to 36,000t/d of ore.

Ore processing

The copper is recovered directly from the ore using a solvent extraction-electrowinning (SX-EW) process. Crushed ore is placed in low heaps built on sloping, impermeable pads for heap leaching and the metal dissolved by repeated application of sulphuric acid solutions. The pregnant solution is collected for copper recovery by electrowinning. Uncrushed run-of-mine ore is leached on separate pads with the pregnant solution also being transferred to the electrowinning circuit.

The copper-bearing leacheates are purified by removing metals other than copper using organic solvents, and the copper is then extracted by electrowinning to produce high-quality copper cathodes. These are then transported 120km by truck and rail to the port at Antofagasta for shipment worldwide.

Production

Lomas Bayas was commissioned in mid-1998, when 19,300t of copper were recovered from 2.6Mt of ore mined. Initially, Lomas Bayas experienced considerable difficulty in reaching design capacity owing to higher-than-anticipated levels of chlorides and nitrates that depressed SX performance. After some modifications and a change of SX reagent, Boliden raised output by 16% in 2000. In 2001 performance continued to improve, output totalling 56,300t of copper.

The mine produced 62,041t of copper in 2004, a new record and nearly 2,000t more than in 2003. In 2005, its output rose again, to 63,147t.

This involved the production and leaching of 13.5Mt of 0.5% copper ore in the heap-leach operation, and 22.4 Mt at 0.22% copper of run-of-mine ore.

Environment

Lomas Bayas’ location in the Atacama Desert means that the principal environmental issues are dust control and water management. Water is pumped 135km to the site and the mine has maximised water recycling and conservation. Dust emissions are regularly monitored, the source identified and control strategies devised and implemented.

Expansion

Falconbridge had an option on the Fortuna de Cobre property, adjacent to Lomas Bayas, that had to be exercised by mid-2006. It began a pre-feasibility study during 2005, as well as driving an exploration tunnel into the orebody for bulk sampling purposes. It also built a pilot plant for metallurgical testwork. Mining here would potentially increase the copper output at Lomas Bayas from 60,000t/y to 90,000t/y, or extend the mine’s life by five years to 2020.

In June 2007, an expansion project to increase annual mine production at Lomas Bayas to 75,000t was approved. The project was successfully commissioned by the end of 2008, at acost of $70m. As a result of the expansion, Lomas Bayas is expected to produce 75,000t/y from 2008 to 2010. Following the expansion, copper cathode production increased by 28% to 36,200t in the first half of 2009.

Lomas Bayas II

Xstrata approved a $293m investment to develop Lomas II, a nearby deposit located 3km apart from the original Lomas Bayas mine. Also referred as Fortuna de Cobre, the mine will enable Xstrata to sustain production capacity to 75,000t/y.

Construction of Lomas Bayas II will begin in the first quarter of 2010. It is scheduled for completion by the second quarter of 2012.