The Idaho cobalt project (ICP) is being constructed approximately 40km towards the west of Salmon, Lemhi County, Idaho, US. Located in East Central Idaho in the historic Idaho Cobalt Belt, ICP is the only environmentally permitted primary cobalt project nearing production in the US.

The preliminary economic assessment (PEA) of the ICP was completed in March 2015, while the feasibility study (FS) was completed in September 2017. Commercial production is anticipated to start in the first half of 2020.

The underground mine is expected to produce 31.77 million pounds (Mlb) of cobalt, 42.82Mlb of copper and 39,241oz of gold over its mine life of 12.5 years.

Formation Capital Corporation, a wholly owned subsidiary of eCobalt Solutions, owns and will operate the project.

Idaho cobalt project development

A three-phase mine development programme will oversee the construction of the processing and ancillary facilities. Phase one construction involved timber clearing works for the soil stockpile area, new and existing roads around the mine site, concentrator pads and a tailings and waste rock storage facility (TWSF). The phase one was completed in April 2010.

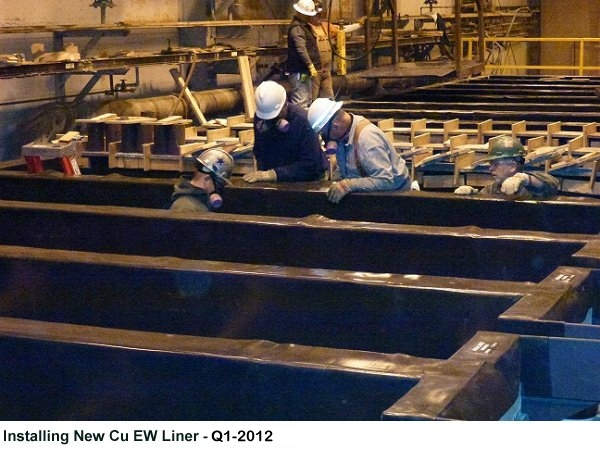

The second phase of construction, which began in mid-June 2011, will produce 400t/d. It includes construction of the mill and ancillary facilities. The ram mine portal, hydrometallurgical facility, tram, mill, water management pond, roads, borrow areas and a soil stockpile area are also to be constructed.

Mill and ancillary facilities are being built on Big Flat, an area between Big Deer Creek and Little Deer Creek. The mill includes a hard ore storage area, a fine ore conveyor, a ball mill grinding circuit, flotation cells, an analytical laboratory, pipelines, dewatering equipment, a water treatment facility and a shipping dock.

Ancillary facilities include power cables, fuel storage tanks, water drainage, warehouse and maintenance plants, administration offices, change house and domestic water disposal.

Phase two was originally scheduled to begin in the second quarter of 2010. Pending funding for the construction, it was postponed to the second quarter of 2011. Development of the mine at depths below the water table will be carried out in the third phase.

The mine was placed on care and maintenance in May 2013 due to unfavourable financial markets and falling commodity prices.

Following the increase in cobalt prices, eCobalt again undertook PEA and feasibility study for the project. An optimised feasibility study (OFS), expected to complete by the end of 2018, is also being undertaken to define the roasting condition of ICP ore to produce clean, low-arsenic, high-value cobalt concentrate product.

Geology and mineralisation

The Idaho cobalt project is located on the eastern portion of the central Idaho Batholith, which comprises Cretaceous-age granitic to granodioritic rocks hosted in Proterozoic-age sedimentary rock. The host sedimentary rocks are on the southern flank, which comprises a large Proterozoic-age marine sedimentary basin dominated by clastic sediments.

The project is situated in the Idaho Cobalt Belt, which is a 35-mile metallogenic district hosting stratiform/tabular copper-cobalt deposits. The deposits are hosted by a thick, dominantly clastic sequence of Middle Proterozoic age sandwiched between late Proterozoic quartz monzonitic intrusions.

Mineralisation identified at the ICP is similar to the mafic sequences of the middle unit of the Apple Creek Formation. The project mainly hosts cobaltite and chalcopyrite along with smaller quantity of gold. It also contains pyrite, pyrrhotite, arsenopyrite, linnaeite, loellingite, safflorite, enargite, and marcasite in small quantities.

Reserves

The Ram deposit of the ICP is estimated to contain 3.66Mt of proven and probable reserves grading 0.47% cobalt, 0.68% copper, and 0.016oz of gold. It is estimated to contain 34.5Mlb of cobalt, 49.76Mlb of copper and 53,286oz of gold.

Mining and processing of ore at the cobalt mine

Ore will be mined using underground mining methods. Two ventilation shafts will be installed in the process. Post extraction, the ore will be conveyed to the mill located at Big Flat.

An overhead tram will stockpile the ram ore and waste rock at 1,000ft height from the portal to the mill. At peak capacity, approximately 32t of dry concentrate and 768t of dry tailings a day will be processed at the mill. The concentrate will be hauled to a processing facility, located off-site.

The ore will be processed at a new processing facility at the Big Flat Hydrometallurgical Complex. Full-time pilot tests are being conducted at the hydrometallurgical complex to ensure a seamless start-up and identify minor issues, if any.

The cobalt processing facility at ICP will use Cytec Industries’ reagents to purify solutions in the solvent extraction process, which will be further refined in General Electric’s equipment for producing high-grade cobalt sulfate heptahydrate crystals.

Off-take of cobalt

eCobalt has entered several non-binding letters of intent (LoIs) for the offtake of cobalt produced at the Idaho cobalt project.

Financial backing for the mine project

The company was allocated up to $92.1m tax-exempt bonds by the State of Idaho in 2010. The bonds include up to $46.7m in recovery zone facility bonds and $45.4m in solid waste bonds. By March 2011, the company raised $80m in equity funds to be used towards the construction of the mine.

Infrastructure facilities at ICP

Power supply for the mine site is enabled by a 69kV power line provided by the Idaho Power Company.

An estimated 960 gallons (768,000 gallons a day) of water a day per ton is required for processing at ICP. The primary source of water for the operation is dewatering of the Ram deposit.

Tailings from both the concentrator and the waste rock material will be stored at a single surface disposal facility.

Contractors involved

The engineering, procurement and construction management services for the project will be provided by JDS Energy & Mining. A LoI was signed between the companies in January 2011. Power for the mining operations will be supplied by Noranda Mining and Intalco Aluminium Corporation.

The construction contract was awarded to Dahle Construction. Geotechnical core drilling, completed in December 2011, was carried out by A&K Drilling.

The feasibility study for the ICP was prepared by Micon International, with support from SNC Lavalin and Dundee Sustainable Technologies.

Samuel Engineering, Langston & Associates, Micon Engineering, Mine Development Associates supported JDS with the construction progress at the mine and concentrator site, and for the production facility construction.

GE Water & Process Technologies (GE) was awarded the contract, in 2015, to conduct crystalliser bench tests at ICP, while Veolia Water Technologies is supplying the water treatment plant.

Environmental impact of Idaho’s mine

The mine will be operated with minimal environmental impact. Low-impact methods including careful disposal of waste rock and tailings will be adopted to protect the water quality. The TWSF and water management pond was designed using data from a geochemical testing programme that was conducted by Formation Metals to describe waste rock and tailings characteristics.

The TWSF will be equipped with a composite under-liner built above a prepared subgrade. It will consist of a low-permeability soil layer below a synthetic liner.

Water infiltrating the tailings and waste rock will be collected in a drainage collection system built above the liner. An adjacent area within the plant will collect the waste rock and tailings. Half of the tailings will be used as backfill underground, while the remainder will be disposed in the TWSF through dry stacking method that avoids the need for a dam.