The Cannington silver mine is located in north-west Queensland, 200km south-east of Mount Isa, near the township of McKinlay.

The deposit was discovered by BHP Minerals in 1990 and the mine was commissioned in 1997 at a cost of approximately A$450m. Full production was achieved in early 1999 and since then capacity was expanded from 1.5Mt/y of ore to over 3Mt/y.

Cannington is one of the world’s biggest producers of silver and lead. The lead concentrate contains 70% lead and over 3,000g/t silver with low levels of impurities. Long-term contracts for concentrate sales have been agreed with Pasminco (now Zinifex) in Australia, Metaleurop in France, Berzelius in Germany, and various smelters in Japan and Korea Zinc.

The Cannington mine is 100% owned by South32. Cannington consists of an underground hard rock mine and surface processing plant, a road-to-rail transport facility and a concentrated handling and ship loading facility in the Port of Townsville.

Cannington mine geology and sulphide ore reserves

Cannington lies in the south-east corner of the proterozoic Mount Isa Block, within the metamorphics of the lower middle proterozoic eastern succession and overlain by 60m of younger sediments. It is divided by faulting into a shallow, low-grade Northern Zone and a deeper, higher grade Southern Zone.

Initial mining will be undertaken in the Southern Zone. Cannington’s major economic sulphides are galena and sphalerite. The silver occurs mainly as freibergite but is also present in solid solution within galena.

At the end of June 2020, the mine contained 20Mt of total ore reserves grading 173g/t silver, 5.35% lead and 3.28% zinc. Total mineral resources were 79Mt at 262g/t Ag, 7.89% Pb and 5.36% Zn. The reserve life of mine (LOM) is 11 years. The metallurgical recovery rates for zinc, lead and silver were 83%, 87% and 85% respectively.

Cannington underground mine

Cannington is an underground mine accessed via a 5,250m-long, 5.2m-high by 5.5m-wide decline. The main, thicker hanging-wall orebodies of the deposit are mined by transverse, longhole open sloping.

During the first year of production, a vertical hoisting shaft with a finished internal diameter of 5.6m was constructed from the surface to 650m for ore haulage. The excavation method involves stripping out a 1.8m-diameter raise-drilled pilot hole and lining with concrete from the surface.

The shaft is equipped with a tower-mounted friction winder and two 9t skips in counterbalance running on rope guides. The skips are hoisted from a loading station on the 610m level and reach a final hoisting speed of 12m/s. On the surface, tipping scrolls in the shaft headframe tip the skips into a surface bin for transfer to the mill’s stockpile.

Lead and zinc concentrate processing

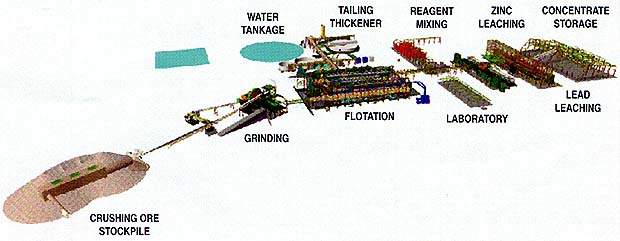

Processing steps used to produce the lead and zinc concentrates include comminution, flotation, leaching and dewatering. Waste water is pumped to a tailings dam with the flotation overflow. The overflow from the lead concentrate thickener is recycled to the lead flotation circuit.

The operation of the concentrator is automated with progammable logic controllers (PLCs), an online sample analyser being used to provide continuous assays on a number of the concentrator streams for silver, lead and zinc. The silver is leached from the lead and zinc concentrates before smelting.

Silver, lead and zinc are extracted from ore using crushing, sequential floating and leaching techniques that yield high-grade, marketable lead and zinc concentrates with a high silver content.

Production at Cannington silver mine

During the year ending FY20, Cannington mined 2,792 thousand wet metric tonnes (kwmt) of ore grading 156g/t silver, 4.7% lead and 3.3% zinc. Payable metal production was 11,792 thousand ounces (koz) of silver, 110.4 thousand tonnes (kt) of lead and 66.7kt of zinc.

Cannington mine expansion

BHP Billiton commenced its Cannington Growth project since 2003, with the aim of improving recoveries, bringing the Northern Zone orebody into production and sustaining ore production at a rate of 2.4Mt/y.

Cannington’s payable zinc equivalent output rose by 9% from 19.8kt to 238.0kt in FY20 as expected higher zinc grades more than offset lower grades Ag and Pb, and the project decreased the mine stock to a normalised level following the Queensland flood event in FY19.

The decline and further progress in underground mine output enabled the introduction of efficiencies in mill throughput, resulting in a 14% rise in ore processed during the FY20.

Transport, storage and export

After dewatering, the lead and zinc concentrates are stored in a 10,000t-capacity storage shed before being loaded into 118t-capacity side-tipping, covered trailer roadtrains by a front-end loader for transport to Cannington’s storage and rail loading facilities at Yurbi on the Matilda Highway. Supplied by Roaduser Research, the three 53.5m-long Icon roadtrains carry eight covered bins mounted on six trailers, loading and unloading taking about 20 minutes at each end of the journey.

The concentrates are stored separately in an 8,000t-capacity shed at Yurbi prior to loading into rail wagons. Queensland Rail has supplied 50 new 63t-capacity wagons for transporting the concentrates to the port of Townsville for export to world markets.

The concentrates are transported by road to the rail loading facility in Yurbi, approximately 15km east of Cloncurry, and by rail to the new mineral concentrate handling facility in Townsville.

Contractors involved

Fluor worked on the design and procurement of machinery for primary crushing, autogenous grinding, differential flotation and tailing disposal, along with grinding, leaching, dewatering, handling and transport of concentrates.