Platinum group metals (PGMs) have long been earmarked as a potential game changer in sustainable development plans, particularly in areas such as emissions control and alternative energy sources. Attractive for their catalytic properties, harnessing them to improve battery performance could mark a significant step for electric vehicles, and even open the door for longer life batteries applied beyond mobility purposes. While the concept has not yet reached commercialisation, Lion Battery Technologies believes they’re close.

The venture was established in 2019 to support the work of Dr Bilal El-Zahab, an assistant professor in mechanical and materials engineering at Florida International University (FIU) who has been investigating the benefits of adding PGMs to battery technology. Specifically, Dr El-Zahab found that lithium oxygen and lithium sulphur batteries have improved efficiency when the PGMs palladium and platinum are added – increasing the battery’s energy density and cyclability. The recent patent has added fuel to the fire and the project is expected to attain marketable results soon, making PGMs a radical up-and-comer in the battery industry.

Batteries to meet a modern world

Speaking with R. Michael Jones, CEO of Platinum Group, he says it was clear two years ago that the state of battery technology was inadequate to meet the demands of a rapidly modernising world.

“Cell phone batteries fade after a year of charging and discharging, electric vehicles (EVs) have heavy batteries over 300kg and still there is concern over range” he says. “The modern world has changed from our grandfather’s flashlight battery.”

While lithium is the clear answer to calls for a revolutionised battery type, existing models suffer from short battery lives and overheating – problems that, alongside charge-rate capability, the work of Dr El-Zahab seeks to address.

“The modern lithium battery is good and is a step forward, but it’s still not what we need,” Jones adds. “Lithium is a likely winner in a battery as it is light and has lots of electrons to work with, so it boasts good electrical properties. But there are other elements which may offer improvements when added to the chemistry of the battery.”

How well do you really know your competitors?

Access the most comprehensive Company Profiles on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

Thank you!

Your download email will arrive shortly

Not ready to buy yet? Download a free sample

We are confident about the unique quality of our Company Profiles. However, we want you to make the most beneficial decision for your business, so we offer a free sample that you can download by submitting the below form

By GlobalDataWhile demand for platinum and palladium is currently in catalytic converters for petrol-powered vehicles, their known ability to catalyse chemical and fuel-processing reactions means they are a good candidate for enhancing battery performance – offering financial and environmental savings in the process.

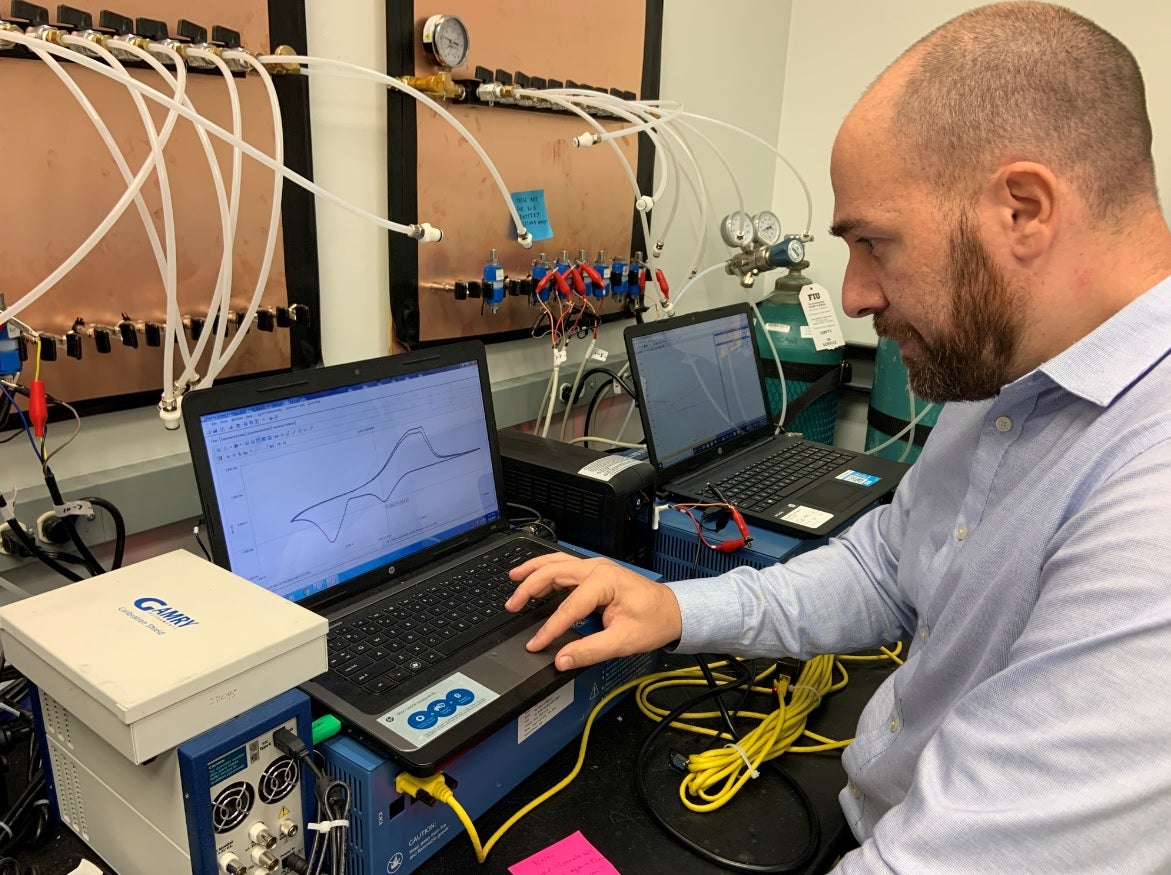

While existing lithium-air and lithium-sulphide batteries can be very powerful, cyclability has historically proven a challenge. In his work, Dr El-Zahab and his team of six specialist nano-materials and battery postdoctoral fellows proved that PGMs helped to not only stimulate the reaction, but also improved the charge-discharge cycle. To determine the effectiveness of these materials in batteries, the team is running ‘hundreds’ of experimental cells, tracking the performance every day and adapting the structure and PGM to find optimal performance.

What’s next?

Progress of the new battery is well underway, with the FIU team completing their first year of research and surpassing their first technical milestone. The patent – entitled ‘Battery Cathodes for Improved Stability’- is a major success for the project, and includes the use of carbon nanotubes and other innovations in a lithium battery. Awarded to FIU, the university signed a sponsored agreement with Lion with regards to research and patent applications.

“The initial patent grant is the first significant milestone towards our objectives to both capitalise on a true cutting-edge innovation and drive demand for PGMs at the same time,” Jones stated in a release on the matter.

Jones believes that as we increasingly adapt our grid to make way for widespread EV adoption, so the market for cheaper, lighter, and more powerful lithium batteries will grow, and ensuring cyclability is maintained will become a priority for many. It is also expected that these novel battery types will be used in a range of applications such as electronic devices.

“Batteries are in the technology now – but a stair step up of 3X to 5X in battery performance will make EVs and devices that much more capable,” says Jones. “It will take three to five years to bring the science innovation into commercial batteries, but the potential is very large.”

Price versus efficiency

While the use of PGMs will likely increase the cost of the battery, Jones says that the price is expected to be partly offset by the battery’s greater efficiency.

“These are great as chemical catalysts, encouraging a reaction,” says Jones. “We already use them in the tailpipes of cars to clean up emissions for this reason. The cathode side of the battery is much lighter than current batteries and the power is higher, which allows for a more powerful battery with longer life compared to current technology.”

While the technology is not yet fully developed, the team affirms that by using carbon nanotubes containing between 10g and 12g of PGMs at the cathode, significant performance and power-to-weight advantages are seen. The company’s target weight, according to Jones, is 144kg for its lithium-air battery and 188kg for its lithium-sulphur battery.

Further patent applications have been filed, with optimism high for the project’s commercialisation in the next few years.

“We are discussing our innovation with commercial battery makers. The interest has been higher and sooner than we thought,” says Jones “We have passed our first year technical milestone and we are approaching our second year target early. We are very pleased with the proof of concept. PGMs can play an important role in the next cutting edge battery innovation.”

Indeed, Anglo American Platinum announced in 2019 that its profit has more than doubled since the previous year thanks to higher PGM prices, showcasing the opportunities inherent in this blossoming sector.