Pilbara Minerals’ wholly owned Pilgangoora lithium-tantalum project is located in the Pilbara region of Western Australia.

Stage one development of the mine was completed in July 2018 and the first shipment of spodumene concentrate was made in October 2018.

Pilbara Minerals is currently undertaking the P680 and P1000 expansions at Pilgangoora, which are expected to be completed in the fourth quarter (Q4) of 2023 and the first quarter of 2025, respectively.

The estimated investment for the P680 expansion project is A$103m ($72m) while investment in the P1000 expansion is A$560m.

Location

The Pilgangoora lithium-tantalum project lies approximately 120km south of Port Hedland and roughly 55km from Pilbara Minerals’ flagship Tabba Tabba Tantalum Project.

The project comprises 34 granted tenements spanning an area of 1,086km².

Pilgangoora lithium-tantalum project expansion details

The P680 expansion project will boost the Pilgangoora plant’s output by 100,000 dry tonnes (dt) annually. It will elevate Pilgangoora’s annual spodumene concentrate production capacity from the current 540,000-580,000dt up to 680,000dt a year.

The primary rejection heavy media separation circuit for the P680 expansion is set to commence operations in the third quarter of 2023, reaching full capacity by the end of 2023.

The P1000 project will expand the overall spodumene concentrate production capacity of the project from 680 tonnes per annum (tpa) to one million tons per annum (mtpa). Initial ore production is planned for the first quarter of 2025, ramping up in the third quarter of the same year.

Pilgangoora lithium-tantalum project geology and mineralisation

Covering an area of approximately 31km², the project hosts three mining licences, namely M45/78, M45/333, and M45/511, as well as two exploration licences, EL45/2232 and EL45/2241.

It is located within the Archean North Pilbara Craton, hosting the East Strelley Greenstone Belt, which is composed of a series of steeply dipping mafic metavolcanic rocks and amphibolites.

The pegmatites extend more than 7km and the mineralisation occurs in a number of north-south trending pegmatites, with strike lengths reaching approximately 1,250m. The pegmatites comprise albite, quartz, muscovitem and spessartine garnet, with the mineralised zones hosting lepidolite, spodumene, tantalite and cassiterite, and small amounts of microlite, tapiolite, and beryl.

Reserves

The Pilgangoora project is estimated to contain proven and probable reserves of 214.2Mt grading 1.19% Li₂O, 103 parts per million Ta₂O5 and 0.99% Fe₂O³ , as of June 2023.

Mining and processing

Conventional open-pit mining, using truck and hydraulic excavator operations, along with drill and blast, is applied at Pilgangoora.

The concentrator plant has an ore processing capacity of 2mtpa, which will be expanded to 5mtpa through stage two expansion of the mine. It is designed to produce chemical-grade spodumene, technical-grade spodumene, and tantalite concentrate.

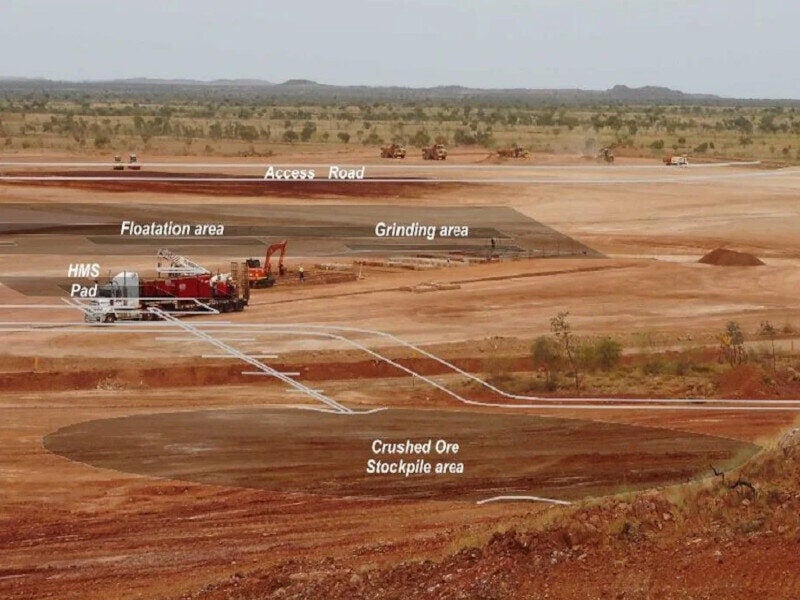

The concentrator primarily integrates a two-stage crushing circuit, a feed preparation facility, a dense media preparation circuit, a gravity preparation circuit, a grinding circuit, and a flotation circuit incorporating a wet magnetic separation facility to reduce the quantity of iron in the technical-grade spodumene product.

The obtained spodumene is transported to the Wedgefield bulk storage facility in Port Hedland for shipping. The tantalum concentrates are packed into 200kg drums and transported in shipping containers to the port.

Mid-stream demonstration plant

In August 2023, Pilbara Minerals announced its final investment decision on the construction of a mid-stream demonstration plant that will enable the production of value-added lithium at the mine.

The demonstration plant is being developed by Pilbara Minerals in a joint venture with Calix, a technology company. It is estimated to require an investment of A$104.9m and is partially funded through a A$20m loan from the Australian government.

Financing for the Pilgangoora lithium-tantalum project

Pilbara Minerals raised A$130m in funding through a senior secured bond issue, an A$80m share placement, and a A$15m share purchase plan for the Pilgangoora project.

The Clean Energy Finance Corporation, a corporate entity of the Australian Government, subscribed to the bonds.

The A$80m share placement included approximately A$53m in commitments from qualified institutional and sophisticated investors in Australia and overseas and a A$27m equity commitment from the company’s off-take partner Jiangxi Ganfeng Lithium.

The expansion project received a loan of A$250m from the Northern Australian Infrastructure Facility and Export Finance Australia in November 2022.

Infrastructure for the Western Australian lithium-tantalum mine

The project benefits from its close proximity to existing major roads, an airstrip, and the Port of Hedland. A reverse-osmosis water treatment plant has been installed to provide potable water while the electricity requirements are met by a diesel-powered generator.

The mining infrastructure includes a maintenance workshop, offices, crib rooms and amenities, a fuel farm, water dams, and dewatering systems. Other major infrastructure for the project includes a tailings management facility, mine waste stockpiles, an airstrip, and accommodation facilities.

A 15-megalitre water storage dam is being built as part of the P1000, including the expansion of the borefield pumping and piping network. An expansion of the existing Pilgan plant with high-speed natural gas generators is under planning to meet the increased power demand. A battery energy storage system is also being considered.

A 300-member accommodation camp has also been built to house the workers.

Off-take agreements

Pilbara Minerals signed off-take memorandums of understanding with eight different chemical and technical-grade customers located in China, Korea, Japan, North America, and Europe by March 2016.

In July 2016, the company signed a binding off-take agreement with General Lithium, a company based in China, for the supply of 140,000tpa of 6% chemical-grade spodumene concentrate from Q1 2018. The agreement is initially for six years and includes an option to extend by a further four years.

The company also entered a long-term binding off-take agreement with Chinese lithium producer Jiangxi Ganfeng Lithium and its subsidiary Ganfeng Lithium, in May 2017, for the off-take of approximately 160,000tpa of chemical-grade spodumene.

Jiangxi agreed to initially purchase spodumene for ten years, with two five-year options to extend by up to a further ten years. It also agreed to take delivery of 25% of the expanded concentrate production capacity from stage two of the project.

Pilbara Minerals also signed two more off-take agreements with China’s Great Wall Motor Company and POSCO, for up to 150ktpa and 240ktpa of spodumene respectively from the 5mtpa expansion project.

Pilbara Minerals, through its strategic partner Contemporary Amperex Technology entered a five-year off-take agreement with Yibin Tianyi Lithium Industry to supply 75,000tpa of spodumene concentrate in March 2020.

Contractors involved

Major consultants involved in preparing the DFS include Como Engineers for the processing plant infrastructure, non-processing plant infrastructure and metallurgical studies, Trepanier for the geological and resource estimate studies, MiningPlus for the mine design studies, ATC Williams for the tailings management facility and geotechnical studies, and Groundwater Resource Management for the hydrogeology and hydrology studies.

The metallurgical test works for the PFS were conducted at Dorfner Anzaplan’s facility in Germany, Nagro Mineral’s facility in Perth, and ALS’ laboratories in Perth and Adelaide.

Through its subsidiary MACA Mining, MACA was awarded the open-pit mining services contract. The contract is initially for a two-year term, followed by three one-year options.

Contract Power Group was awarded a seven-year contract to construct and operate the site power station.

In June 2017, NRW was awarded the site-wide bulk civil earthworks package while a joint venture comprising Action Industrial Catering and Njamal Services was contracted to provide camp management and catering services.

Njamal Services and Pilbara Resource Group were engaged for stage two works through their unincorporated joint venture NPJV.

The engineering, procurement, and construction contract for the second phase of the 2mtpa concentrator was awarded to RCR Tomlinson, in collaboration with Minnovo and Primero.

Primero, an engineering group, was awarded the contract for the construction works associated with the P680 expansion project.