Newmont Mining’s announcement in July 2007 of an agreement which was to see it receive $80m from the government of Uzbekistan to settle the ongoing dispute over the seizure of assets brings to an end the largest direct foreign investment in the country. With the company’s 50% stake in the Zarafshan-Newmont operation transferred, full control of the resources at the Muruntau mine – one of the world’s largest open-pit gold mines – reverts to Uzbek hands.

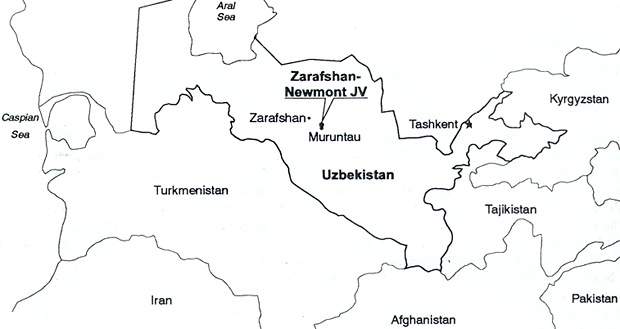

Located in the Kyzylkum Desert area of Uzbekistan, about 400km west of Tashkent, the $250m Zarafshan-Newmont Joint Venture gold operation at Muruntau was the first significant joint venture investment by a Western mining company in the Former Soviet Union (FSU). From its inception until early 2006, the venture had enjoyed good relations with the Uzbek government for nearly 13 years – including tax privileges and a “regime of special favour” – employing around 800 and making more than $500m in payments.

In March 2006, however, the situation changed abruptly when the authorities informed Newmont of impending changes to the tax laws – leading to the arrival in June of a demand for $48m in back taxes to cover the period 2002–2005. The company mounted a legal challenge in the Uzbek courts which led to a ruling against Newmont in August, the seizure of the company’s assets and the cessation of gold exports.

Whether the expropriation of Newmont’s assets resulted from the wider worsening of relations between Uzbekistan and the West after the bloody put-down of the uprising in Andijon in May 2005 or low tax receipts and a need for hard currency, the dispute spiralled. In September 2006, Newmont wrote off the book value of its Uzbek stake and in October, filed two international arbitration claims against Uzbekistan – in Washington and Stockholm. The recently reached settlement brings the outstanding claims to a close and ends the involvement of the world’s second largest gold mining company in the operations.

Newmont’s involvement at Muruntau dated from 1990, when a Newmont geologist attending a conference in Moscow joined the first team of Western experts to visit the mine, which extracts about 21Mt/y of gold ore that is processed and refined to 99.99% gold on site. In February 1992, only six months after Uzbekistan became an independent republic, Newmont Gold (Newmont Mining 91%) signed a 50/50 joint venture agreement to treat the stockpiled ore. The Uzbek partners are the State Committee for Geology and Mineral Resources (Goskomgeologia) and the Navoi Mining and Metallurgical Combine.

Ground was broken in October 1993 and the first gold was poured in May 1995. The European Bank for Reconstruction and Development (EBRD) arranged a $135m debt facility, together with Barclays and other banks.

Geology and resources

The project’s resource consists of low-grade gold-bearing material that was mined from the Muruntau quartz-stockwork system, hosted in metamorphosed sediments, over a 25-year period. Ore production during this time has exceeded 350Mt, with a further 600Mt of reserves. Of seven ore types occurring in the Muruntau pit, three have traditionally been stockpiled as untreatable using former Soviet technology. Newmont’s heap-leaching technology was used to treat the sub-economic ore which had been stockpiled since the Navoi combine started production in mid-1969. About 90% of the Muruntau gold is free and associated with silicification.

When operations started this stockpile comprised approximately 245Mt of material, estimated to contain 8.2Moz of gold. In January 2001, the company acquire the rights to a further 150Mt resource grading 1.44g/t, which was planned to extend the project life to 2013 and the EBRD provided a further $30m for related leach pad expansions. Newmont’s equity gold reserves were 1.7Moz at the end of 2005 – written off during the dispute.

Ore processing

No mining as such was required since feed material is loaded directly from the stockpiles. The $225m plant engineering and construction contract was awarded to the Bateman Group. The plant was designed to yield 400,000oz/y or better from higher-grade feed in the first phase, with output later dropping to 250,000oz/y.

Material is reclaimed from the stockpile in 25m-high slices by Caterpillar 992 loaders and fed to the 2,000t/h-capacity primary Nordberg Lokotrack 160 mobile jaw crusher. This is linked to a mobile apron feeder that discharges to an intermediate stockpile. From here, Nordberg and MAN Takraf conveyors feed the stationary plant. Four Master Magnets overband tramp metal separators are fitted. The one secondary and two tertiary crushers are Nordberg MP1000 cones and the 16 quaternary units are Cemco Vertical Shaft Impactors. Crushing capacity is 37,800t/d and the final product is 100% –3.7mm.

The single leach pad is loaded in eight, 10m-high lifts by a series of conveyors and stackers supplied by Laurel Engineering. Leaching takes 49 days and a conventional Merrill-Crowe process recovers 65% of the gold contained in the ore. The precipitate is melted on-site to produce gold-silver doré, which is refined to 99.99% purity at Muruntau for export. In the first half of 2003, the joint venture placed 3.6Mt on the leach pads, averaging 1.5g/t gold.

Production

Gold output improved steadily after leaching started, while costs fell. In 1996, the first full year, 12.74Mt on the leach pad yielded 326,500oz of gold at a cash operating cost of $225/oz, but in the following year, 14.6Mt of ore was leached, yielding 430,100oz at $204/oz. Recent outputs have been lower – 391,300oz in 2003 and 309,800oz in 2004 (from 7.46Mt processed ore) – while cash operating costs have risen since 2002, to $134/oz in 2003 and $162/oz in 2004. On the other hand, cost increases have been offset by better mill recovery – 95.4% in 2004 compared with 92.9% in 2002. Gold sales in 2005 totalled 245,000oz, with production scheduled to continue until 2011.