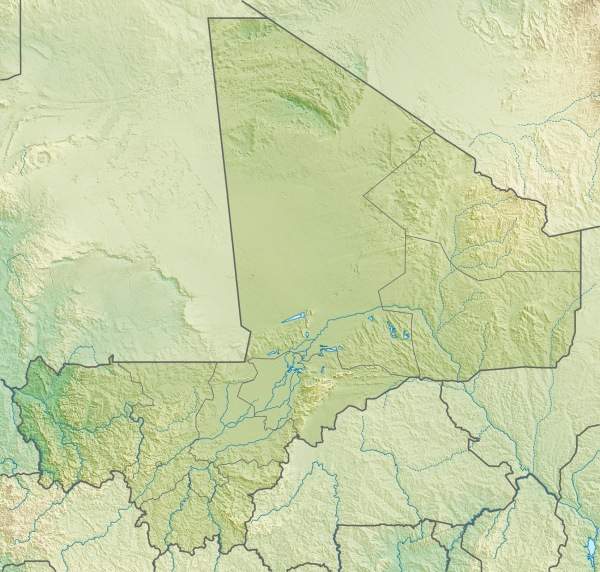

Yatela is an open-pit gold mine located 50km southwest of the city of Kayes in Mali. It covers an area of 195km² and is 80% owned by the Sadiola Exploration Company (SADEX), a joint venture of AngloGold Ashanti and IAMGOLD. The remaining 20% stake in the mine is owned by the Mali Government.

Operations at the Yatela gold mine officially commenced in September 2001, with an initial ten-year mine life. The mine was constructed a month ahead of schedule and below budget at $73m.

It was designed to produce 1.4 million ounces (Moz) of gold in the first six years at an average grade of 3.6g a ton (g/t).

The mine was operated towards the western end of the pit and was nearing closure in 2009. It was originally scheduled to close down in 2010. However, an 18-month exploration programme that began in October 2010 increased the resource base and mine life up to early 2012.

The mining activities at Yatela Gold Mine were suspended in September 2013, whereas the processing of heap leach pads ores will continue until 2016.

The exploration programme was approved in May 2009 at a $14.9m investment. Drilling performed adjacent to the main Yatela pit and in the north-east of the Alamoutala satellite pit projected encouraging results, due to which an additional $2.2m was approved to proceed with the extension.

Background to operations at the Yatela gold mine

Small-scale mining was carried out for more than 300 years in the Kayes region of Mali.

The Yatela deposit was identified by SADEX during the exploration of Sadiola deposit in 1987. The Yatela concession was then owned by Eltin of Australia who had also been exploring the region. In 1997, SADEX signed an agreement to buy the concession from Eltin and the transaction was materialised in 1998.

The feasibility study was conducted by AngloGold in 1999 following the receipt of development permit in 2000 from the Mali Government. AngloGold was later merged with Ashanti to form AngloGold Ashanti.

Geology and reserves of the mine area

The Yatela deposit is located in the north of the Malian portion of the Keniéba-Kedougou window with Kofi formation sediments. These sediments comprise of carbon-rich and impure lime stones with minor tuffs and acid volcanics.

The total reserves at the time of commencement of production were 1.34 million tons (Mt) grading at 3.7g/t and the total measured and indicated resources were 28Mt at 2.5g/t.

As of December 2010, the proven and probable reserves totalled 1.51Mt graded at 1.6g/t of gold.

The attributable production in 2012 was 29,000oz.

Mineralisation of the Kayes region of Mali

Mineralisation occurs in the troughs developed over the carbonates. The 220m-deep troughs comprise unconsolidated ferruginous sand and clay.

The ore zone lies on top of the thick layer of angular blocks belonging to Seroukoto sandstone and shale, which in turn is covered by a fine sand unit consisting of pisolithic gravel layers and laterite rubble.

Mining and processing at the Yatela open-pit gold mine

Ore from the mine is extracted from the main pit as well as the satellite pit at Alamouta. The main pit is 1,300m in length, 600m-wide and 220m-deep.

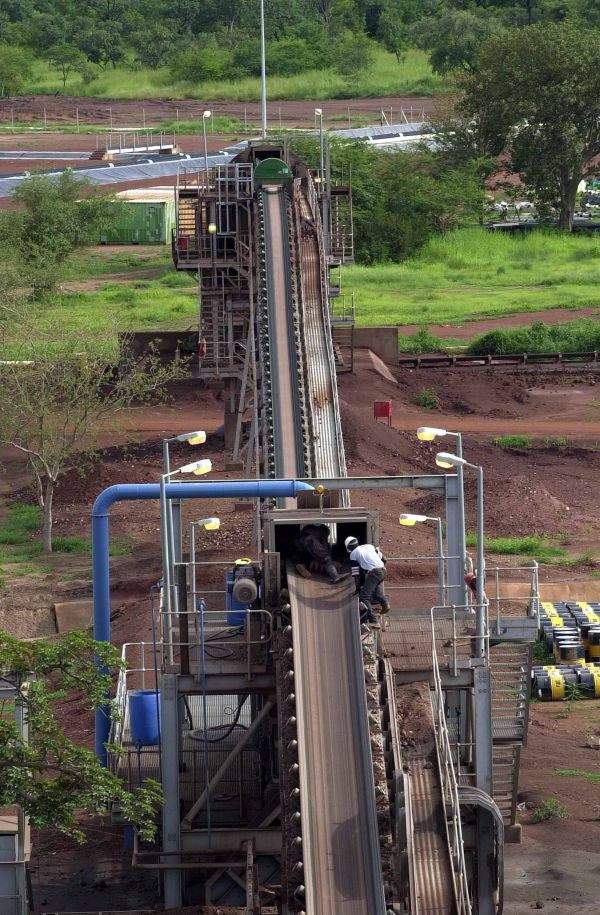

The mined ore is treated at a heap-leach pad and carbon loading that was commissioned in 2001. The extracted ore is crushed in the agglomeration drum and the output is transported by an overland conveyor, mobile conveyor and radial stackers to build a three-lift heap leach pad.

Cement added during agglomeration ensures structural stability and adequate filtering up to the lower lifts. A cyanide solution is pumped through the pipes to feed the pads for filtering purposes. The solution is pumped through carbon-filled columns to strip gold.

The carbon is eluted and the gold is trucked to the smelter at nearby Sadiola processing plant.