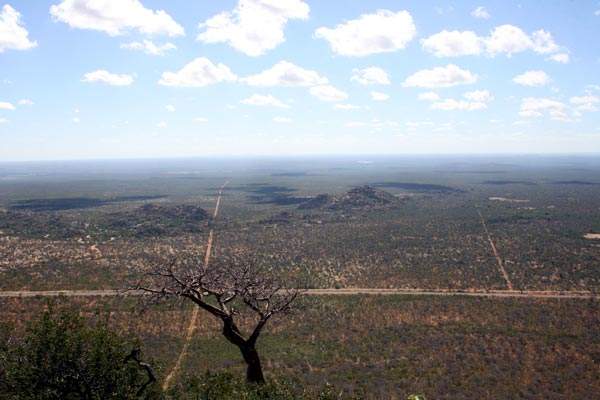

The Vele colliery project is located on the northern border of South Africa’s Limpopo province. The mine spreads across ten farms with 8,663ha of land.

It is owned by Limpopo Coal Company, in which Coal Africa Limited (CoAL) holds 80% of Limpopo Coal’s shares. Eyesize Coal holds the remaining 20% shares. In 2009, CoAL concluded agreements to acquire 20% of the remaining shares of the Vele project to bring its ownership to 100% subject to the grant of NOMR by 12 December 2009. On behalf of Limpopo Coal, CoAL will administer the day-to-day activities of Vele.

CoAL announced a revised mining schedule for both opencast and underground sections in May 2009. The revised schedule is expected to improve coking coal yields, reduce mining costs and extend the mine’s life to 2040.

After receiving prospecting rights, CoAL obtained a New Order Mining Right from the South African Department of Mineral Resources on 22 March 2010. There were several objections to CoAL’s plans including a land claim over the area and protests from environmental, cultural, political and youth groups as the project is within 5km of a World Heritage Site.

The environmental management plan, submitted as part of the NOMR application, has also been approved. Following the grant, CoAL is prepared to begin Phase I of the project.

Contractors

In February 2009, CoAL selected MCC Contracts, a division of Egstra Holdings, as its preferred partner to conduct opencast mining operations. Mulilo Energy and China Railway Construction Company are expected to supply the base load power to the mine.

Geology and reserves

The Limpopo coalfield is a part of the Tuli Block coalfield, which is characterised by the narrow deposits of the Karoo Sequence rocks on the southern bank of the Limpopo River. It consists of three geological entities – the Limpopo Mobile bet basement (3.4 – 2.0 billion years old), the Karoo sequence (240 – 160 million years) and Quatemary deposits (<10 million years).

The mine has estimated resources of 721mt of coal, containing coal 7-9.5m thick, sulphur of 1.2%, and raw ash content of 12%. Measured resources have been estimated at 158 million while indicated resources stood at 324 million.

Vele is a multiple seam deposit with three coal horizons. They are all interbedded coal and clastic units with varying coal percentages. The coal thickness is greater than the clastic partings and the interburden thickness is greater than the thickness of the individual coal horizons.

The bottom coal seam is of higher grade at 3-4m and is mined in both opencast and underground operations. The middle coal seam is mined only in the open cast operations.

Phases of development

Vele will be developed in four phases: construction and commissioning; a build-up period; operational and decommissioning; and closure.

Construction and commissioning began in 2009 and will last until 2011. During this period, 2,600 employees, including 100 full-time employees and 2,500 contract based employees, will be engaged in the construction and development of infrastructure. The key activities include establishing infrastructure and service areas, and mining coal from box-cuts. The right to mine has already been obtained.

Phase I will be completed at a capital cost of ZAR450m ($60m). Due to delays in obtaining the NOMR, the capital expenditure increased from the original ZAR350m ($47m). During Phase I, a modular treatment plant will be set up that is expected to produce one million saleable toes of coking coal a year. The plant’s earthworks and civil construction have already begun. Production is scheduled to begin by the end of 2010. By the third quarter of 2010, the construction and preparation will be completed.

The second phase will be implemented from 2012-13. Production levels of about five million primary saleable tons per annum will be built during this phase. Phase II of the project will oversee the construction of a full-scale coal treatment plant. The plant, already designed by Dowding Reynard & Associates, is expected to produce 5MT of blend coking coal annually. On reaching this production rate, underground operations will be commissioned.

Mining and processing

Opencast and underground methods will be used at the site. Two box-cuts will allow access to the coal reserves.

The East pit and the West pit opencast mines are designed to produce up to ten million tons per annum. On average 800,000tpm of coal is expected to mined based on the overburden thickness. The removal of the topsoil, overburden and interburden would be carried on through trucks and shovels and separate coaling fleets would transport the coal from the pit to the ROM tip.

The underground mining operations will have five continuous miner sections to mine 4.5 million ROM tons to reach the monthly saleable tonnage. A high seam continuous miner, four coal haulers, two roofbolters, a feederbreaker and an LHD will be employed.

The main development section will have a bord-and-pillar layout to mine standard square pillar consisting of five intake roadways in the middle and two return airways on each side.

Ore processing

The ROM coal obtained from the opencast tip is fed through the processing systems. After passing through a vibrating grizzly screen, jaw crusher, heavy duty sizing screens and a rotary breaker the 400mm-sized coal (80mm in underground mining method) is reduced to -70mm feed to plant (FTP) coal.

The -70mm FTP coal is then fed into FTP coal bins reducing the size to 15mm (12mm in underground mining method). The pulp is pumped into a dense medium cyclone where the coal and discard are separated. The discard is drained and rinsed free of magnetite and discharged onto a discard conveyor returning to the open cast pit by a hauler. The product coal is then drained and rinsed free of magnetite and fed into double roll crushers through a conveyor, reducing the coal size to 15mm.

Vibrating feeders and reclaim conveyors reclaim the 15mm coal and discharge it into a mixing tube where magnetite medium is added and the pulp pumped to rewash dense medium cyclone separating coal and middlings.

Middlings are then drained, rinsed and discharged to the middlings coal stockpile. The middlings and discard products will be dewatered by cyclones and dewatering screens before being discharged.

Production

The planned production capacity of Vele is 5mtpa at full production. To achieve this production target the mining rate is fixed at 14 million tonnes per annum. Of the total production, 2.5mtpa of coal will be for Arcelor Mittal’s domestic consumption.

To produce 5mtpa of coal, the total capital expenditure is expected to be about $39.3m.

Transport and handling

Haul trucks will initially transport coal to the nearest rail siding in Musina until the feasibility study is complete. A new rail link or conveyor belt will eventually be constructed for transporting coal.

To deliver the coal, 31 trucks carrying eight loads per day with 60t payload capacity each would be required. These trucks are expected to 28 days a month during construction until full production.

In addition, staff transport from the town to mine will require five staff buses, 90 personal transport vehicles and 20 heavy duty vehicles for suppliers in 2009.