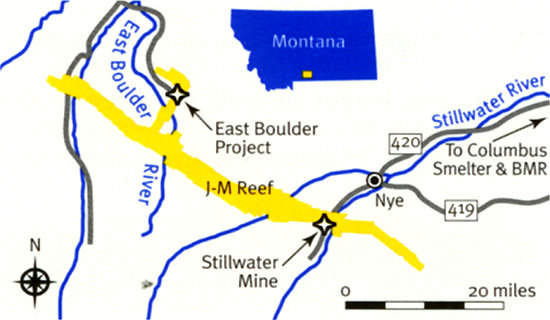

Stillwater and East Boulder are platinum/palladium mines operated by Sibanye-Stillwater in Montana, US. The Stillwater mine is in the Beartooth Mountains, 130km southwest of Billings, Montana.

The East Boulder project, 20km west of Stillwater, was developed with an investment of $370m. Stillwater and East Boulder mines began production in 1986 and 2002, respectively.

The shallow to intermediate level underground platinum and palladium mines are located within the Custer and Gallatin national forest and near the Nye and McLeod towns.

Stillwater and East Boulder mines were initally operated by Stillwater Mining Company, which was acquired by Sibanye-Stillwater for $2.2bn in May 2017.

The annual production from the Stillwater mine is approximately 380,000oz while the East Boulder operation produces 230,000oz per year (oz/y).

Geology and reserves of the Stillwater mine

The operations involve the extraction of PGM ore available in the J-M reef of the Stillwater complex. The J-M Reef is considered as the world’s highest-grade PGM deposit.

This is a large syngenetic, mafic/ultramafic layered complex in which the layering consists of bands of norite, gabbro and anorthosite.

Crystal settling allowed the heavy minerals to settle to the base with the lighter siliceous minerals remaining at the top.

Platinum-group metals (PGMs) occur in a layer averaging 2.4m-thick and are associated with pyrrhotite, chalcopyrite and pentlandite.

As of December 2019, Stillwater is estimated to contain mineral reserves of 26.8Mt at a grade of 19.4g/t containing 16.7Moz, while East Boulder is expected to hold 21.5Mt of reserves at 14.7g/t with 10.2Moz of contained PGM.

Mining at Stillwater and East Boulder operations

The mining at Stillwater mine has two main sections, the existing Stillwater operation and the Blitz project.

Blitz is part of an expansion programme and began production in October 2017. The production from the Blitz expansion project is currently 75,000oz annually and is expected to reach 300,000oz/y by 2022. Stillwater has a mine life of until 2046, which is expected to increase beyond 2055 with the reserves from Blitz. The life of mine of East Boulder is up to 2056.

The Stillwater and East Boulder operations produce 78% of palladium and 22% of platinum.

The mine has adits and laterals driven in from the Stillwater Valley side. There is also an internal decline and shaft.

Three stoping methods include mechanised captive cut-and-fill; ramp-and-fill using hydraulic drill jumbos and LHDs; and sub-level stoping. Declines parallel to the orebody allow entries to be made into the stoping area by overhand methods. Sub-levels are driven on lifts and drilled downwards. Blasted ore is recovered from below using LHDs and stopes are paste backfilled.

The 5,443t/d underground crushing station receives ore from upper levels via ore passes and crushes it to –150mm. The ore is then conveyed to holding bins before loading in the 9t-capacity skips. Approximately 60% of the ore is transported to the mill via a 600m shaft, while the remainder is transported by rail or truck. The Blitz section of the operation is accessed via two portals, while East Boulder is accessed by two 5,800m-long decline tunnels.

Selective mining was used to improve resource recovery and cut production costs.

Ore processing

The ore obtained from the operations undergoes crushing and concentration at the processing plants located at the mines. Ore is stored in a 3,175t silo before being fed to a SAG mill. Oversize is passed to a ball mill while undersize is cycled to flash flotation circuits. The float product is thickened, the concentrate containing 1,700g/t PGM. Tailings from the flash flotation are fed to hydrocyclones and the overflow is fed via conditioner tanks to the rougher/scavenger/cleaner flotation circuits.

Scavenger float is recycled via a regrind mill while the tailings are drawn off.

Hydrocyclone underflow is fed to a flash flotation cell from which the underflow is fed to the thickener along with the cleaner overflow. Thickened concentrate is transported to the smelter. The float tailings are sent to the sand plant for incorporation in backfill.

The concentrates are further processed at the company’s smelter and base metals refinery in Columbus, Montana. At the smelter, where a new 90t/d furnace was commissioned in late 1999, the concentrate is upgraded to produce matte containing approximately 16,000g/t PGMs, plus small amounts of rhodium, gold, nickel, copper and silver. Matte is refined to produce filter cake containing 60% PGMs, which is shipped to metal refiners in the US and Germany. The smelter also recycles spent auto-catalysts to recover their PGM content.

The design capacity of the concentrator at Stillwater operation is 3,100tpd and the utilisation rate currently stands at 92%. The 1,800tpd East Boulder concentrator is currently operating at a utilisation rate of 91%.

Approximately 55% of the mill tailings at the Stillwater mine and 50% at East Boulder are used for backfill.

Future ore production at the PGM mines

The Blitz project is anticipated to expand the existing mine 6,000m to the east of the current operations. The company is expected to commission ten producing areas at the section by the end of 2022.

An incremental expansion of mining, known as the Fill the Mill Project (FTMP), is planned to increase production at the East Boulder mine by bringing a seventh ramp system into production. Ramp-up is expected to start in the fourth quarter of 2020 and will fill the mill capacity, with production projected to increase from the current 230,000oz to 275,000oz.