The Stibnite Gold Project (formerly Golden Meadows Project) is located in the historic Stibnite-Yellow Pine mining district in central Idaho, US. Mining activities at the project site were performed by former owners between 1925 and 1997. The project is now 100% owned by Midas Gold, who plans to redevelop the brownfield site with an investment of $1.12bn.

The project involves the combined development of the Touquoy and the neighbouring Beaver Dam gold mines.

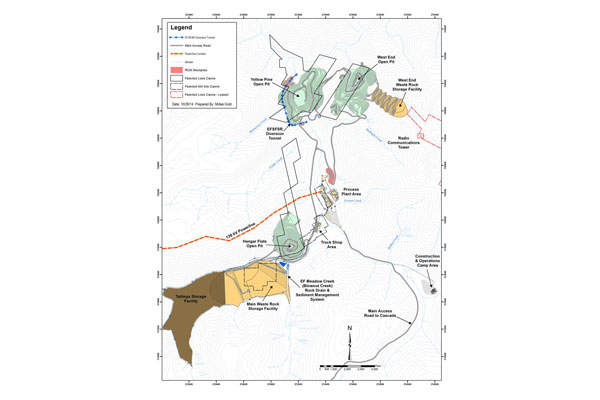

The project hosts three deposits, namely Yellow Pine, Hangar Flats and West End, with the distance between each deposit being less than 3km. The project is ranked the eighth biggest gold mine in the US, based on gold reserves.

Midas Gold intends to produce 4.04 million ounces (Moz) of gold and other by-products, including 2.07Moz of silver and 99.8Mlb of antimony from the mine. The preliminary economic assessment (PEA) for the project was completed in 2012, while the preliminary feasibility study (PFS) was completed in December 2014.

The project is expected to generate approximately 700 direct and indirect jobs during the first three years of the construction phase, as well as 1,000 direct and indirect jobs during the estimated 12 years of operations.

Geology and reserves of Stibnite gold project

The main rocks within the project area include quartz monzonite and related rocks of the Idaho batholith (Cretaceous age), featuring large roof hangings of metamorphosed sedimentary rocks such as quartzite, quartzitic conglomerate, mica schist, metamorphosed limestone, dolomite and tactite. The gold in the deposits is contained primarily within pyrite and arsenopyrite.

The project is estimated to hold indicated resources of 104.5Mt, containing 5.46Moz of gold graded at 1.63g/t, 8.9Moz of silver graded at 2.65g/t and 155.16Mlbs of antimony graded at 0.05%, as of September 2014.

As of September 2014, inferred resources are estimated to be 25.16Mt, containing 1.06Moz of gold graded at 1.32g/t, 1.74Moz of silver graded at 2.15g/t and 25.9Mlbs of antimony graded at 0.05%.

As of September 2014, probable mineral reserves are estimated to be 98Mt, containing 4.57Moz of gold, 6.96Moz of silver and 137.03Mlbs of antimony, graded at 0.047g/t, 0.071g/t and 0.070% respectively.

Mining and processing at the Stibnite Gold project

The Idahoan gold mine will use conventional open-pit mining methods to mine the deposits, with the leased mining fleet including 200t haul trucks and loaders.

With a capacity of 22,050t a day and designed to process all types of mineralisation, a processing plant has been envisaged for the project.

The ore will undergo crushing, milling and treatment using the sequential flotation method. The recovered antimony is intended to be shipped to a third party, while the resultant gold sulphide concentrate will be processed on-site using pressure oxidation (POX), complemented by agitated tank leaching to produce gold-silver doré.

Certain amounts of oxide material will also be milled and made to go through tank leaching to recover gold and silver.

Infrastructure at Midas Gold’s gold mine

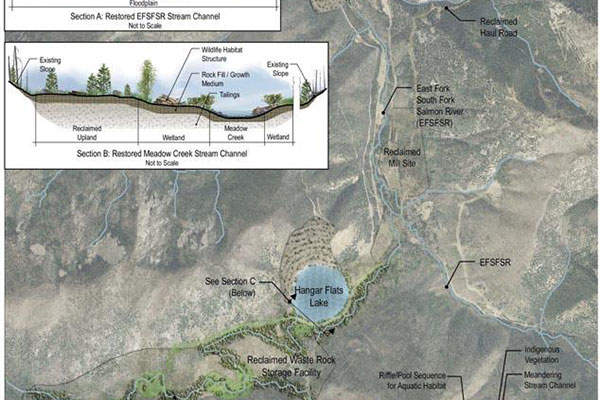

The project will involve the construction of a single tailings management facility (TSF) and the main waste rock storage facility (WRSF), with a combined storage capacity of 210Mt, as well as the construction of the West End WRSF. The electricity required for the project will be sourced from the state grid via a power line installed along an existing right-of-way.

Ancillary infrastructure will include buildings to primarily house administration offices, an assay lab, warehouses, and accommodation facilities. The existing Burntlog Road will be upgraded, and a fish passage tunnel will be provided for the first time at the site since its blockade in 1938.

Key players involved

The PFS report was prepared by M3 Engineering & Technology (M3) with assistance from Kirkham Geosystems for the geology, drilling, data verification and mineral resource estimates. Blue Coast Metallurgy assisted in the mineral processing and metallurgical testing, while Independent Mining Consultants provided assistance in the mine plan, mineral reserve estimates and associated capital and operating costs.

Allen R Anderson Metallurgical Engineer performed the studies for the recovery methods, HDR Engineering performed the studies for the access road, and Tierra Group International performed the studies for the tailings, water management infrastructure and closure.

The PEA was prepared by SRK Consulting, who was assisted by Ausenco Solutions Canada for studies on the infrastructure and mineral processing, Blue Coast Metallurgy for metallurgy, RTR Resource Management for the permitting and social and environmental considerations, and JDS Energy and Mining for project management and economic analysis.