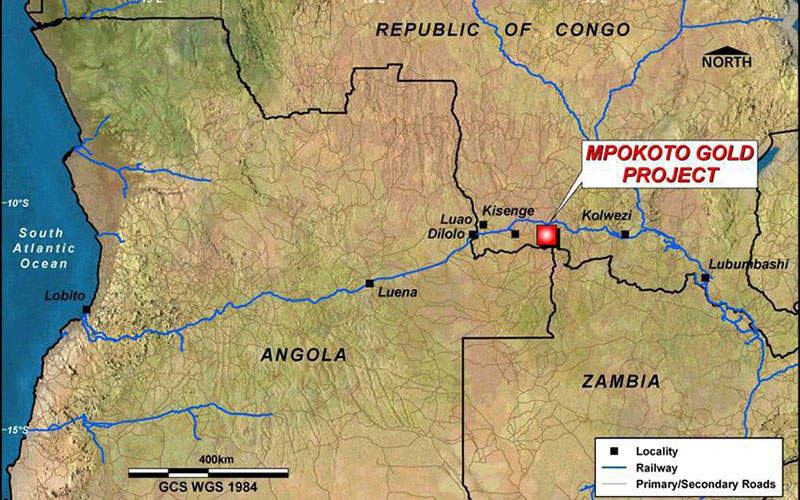

The Mpokoto gold project is located approximately 250km west of the mining town of Kolwezi, within the Katanga Province, Democratic Republic of Congo, and approximately 25km from the Zambian border.

More than $20m was invested for the project’s exploration activities by its former operators Cluff Gold, Gold Fields, and Casa Mining. Armadale Capital now owns 80% of the project through its subsidiary Mines d’Or de Kisenge (MDDK) while the remaining 20% is owned by Miniere de Kisenge-Manganese, a Congolese state-owned company.

The initial scoping study for the project was completed in April 2014, and was further updated in October 2014. The definitive feasibility study (DFS) is underway and production is anticipated to start in 2016.

The total investment to bring the Congolese mine into production is estimated to be $20.42m. The mine is expected to have a production life of nine years, during which it is anticipated to produce approximately 231,000oz of gold (Au).

Mpokoto gold project geology

The Mpokoto area hosts a meta-volcanic-sedimentary succession, referred to as the Lukoshi formation, which was metamorphosed into amphibolite facies.

The mineralisation is hosted within a sheared, inter-layered, conglomeratic sandstone of the palaeoproterozoic age (2.5 billion to 1.6 billion years) overlying the metamorphosed basement. The mineralisation is open at depth and along strike.

The deposits contain oxide ores, as well as transition and fresh un-weathered material.

Reserves of Armadale Capital’s flagship project

As of October 2014, the project was estimated to hold a combined JORC 2012 Code-compliant inferred and indicated resources of 14.6 million tonnes (Mt) grading 1.45g/t Au at a cut-off grade of 0.5g/t, containing 678,000oz of gold.

Mining and processing at the Congolese gold mine

The project will be mined through conventional open-pit methods. Free digging will be performed up to depths of 30m-40m to extract the oxide ores, with loading and hauling performed by a hydraulic shovel and 60t dump trucks respectively. Drill and blast methods are envisaged for extraction of the transition and fresh un-weathered material, located below the oxide bearing layer.

The initial processing plant conceived for the project will treat the oxide ores. The plant will integrate scrubbing and milling circuits, a batch Knelson concentrator to recover the free gold, and a flotation circuit.

For processing the transition and fresh un-weathered material, the process plant will be modified after 3.5 years, with the inclusion of a regrind ball mill to grind the flotation concentrate, and a carbon-in-leach (CIL) circuit to leach the flotation tailings.

Infrastructure at the gold mine in Katanga province

The project benefits from its close proximity to a national highway and the recently reconstructed railway line connecting the Atlantic port of Lobito, Angola, to the Congolese border at Luao / Dilolo. It will further benefit from the proposed reconstruction of the railway line between the Angolan border and Kolwezi.

Major infrastructure for the project will include tailings storage facilities (TSFs), waste dumps, a raw water pipeline connecting the site to a nearby river, a water reservoir, a water treatment plant, a sewage treatment plant, a pump station, power supply facilities, an accommodation camp, and buildings integrating a workshop, offices, change house, first aid room, stores and a parking area, and internal access roads.

Key players involved

Africa Mining Contracting Services group (A-MCS) has signed a heads-of-terms agreement with Armadale to assist with the DFS and arranged a $20m financial package for the project, to serve as the mining contractor, operating the project.

The project’s scoping study was compiled by Bara Consulting with assistance from CSA Global for the geological studies and resource estimates, and Appropriate Process Technologies (APT) and Peacocke and Simpson (P&S) for the metallurgical test work, metallurgical recoveries and the process plant design and cost estimate.

Bara Consulting and CSA Global are further involved in compiling the DFS report. Alpha, a drilling company based in Botswana, was contracted in late-2015 to supply two drilling rigs for the project.