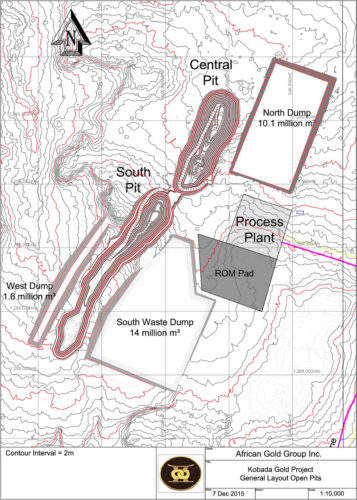

Covering an area of approximately 135.7km², the Kobada Gold Project is located approximately 125km south-south-west (SSW) of Bamako, the capital city of Mali, and is adjacent to the Niger River and the border of Guinea.

African Gold Group (AGG – Barbados) owns the project through its subsidiary AGG Mali. The project was acquired in 2005 from COGEMA, a subsidiary of Bureau de Recherches Geologies et Menieres (BRGM, the Geological Survey of France).

Preliminary economic assessment (PEA) for the project was completed in December 2014, whereas the definitive feasibility study (DFS) was completed in February 2016. The detailed design of the processing plant and ordering of long-lead equipment are scheduled to start in July 2016 and the processing plant is anticipated to be commissioned in September 2017.

The Malian gold project is estimated to require a pre-production capital of $45.4m. The production life of the mine is estimated to be eight years, with gold production expected to average at 50,000oz a year.

Geology and mineralisation

The project is located on the western part of the Bougouni Basin, primarily hosting sedimentary rocks with minor tholeiitic volcano-sedimentary intercalations, which were deposited during the early-Proterozoic Birimian period.

The project area is primarily composed of laterite plateaus down to a maximum depth of 25m, with a minor presence of granitic rocks. Underneath the laterite plateaus is saprolite. The mineralisation is hosted in the laterite and saprolite, and extends for a minimum strike of 4km.

Reserves at Kobada gold mine

As of November 2015, the combined measured and indicated resources from the project were estimated to be 18.1Mt grading 1.1Au g/t, containing 622,000oz of gold, whereas the inferred resources were estimated to be 10.3Mt grading 0.9Au g/t, containing 290,000oz of gold.

As of February 2016, the combined proven and probable mineral reserve was estimated to be 12.7Mt grading 1.25g/t Au, containing 511,000oz of gold.

Mining and processing at AGG’s flagship project

The deposits will be mined using the open-pit mining method, deploying 40t trucks and 70t excavators, by a mining contractor.

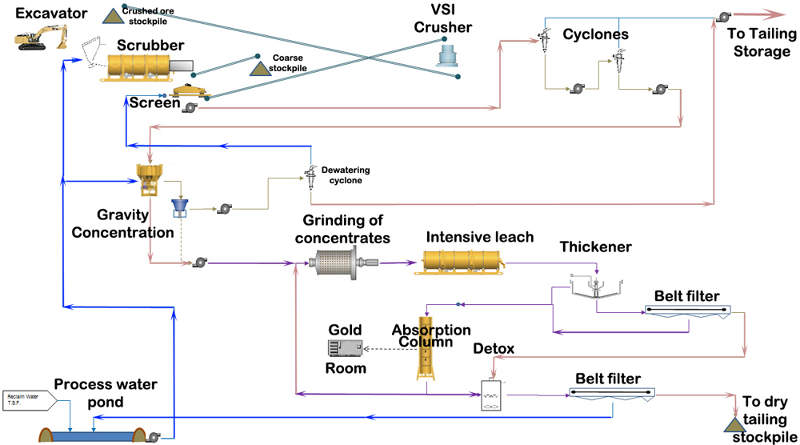

The processing plant proposed for the project will be capable of treating 1.6Mt of ore a year. It will be equipped with a 7.9m-long and 3m-diameter scrubber, a vertical shaft impactor (VSI) crusher, hydrocyclones, a gravity concentration circuit integrating InLine Pressure Jigs (IPJs) and Knelson centrifugal concentrators, a grinding circuit, intense leach reactors, a thickener, a belt filter, an AuRIX resin adsorption column, and a gold room integrating resin stripping, electrowinning and gold smelting systems to produce gold dorè.

The tailing from the pre-concentration and gravity concentration circuits will be pumped directly to the inert tailing storage facility (TSF), whereas the solid residue from the belt filter will be treated in a sulphur dioxide (SO₂) and oxygen (O₂) cyanide destruction circuit and stored in a purpose-built, lined facility within the waste rock dumps.

Infrastructure for the Mali-based gold mine

The raw water requirements for the project will be sourced from the local river and onsite-borewells and stored in a water storage facility at the site, while a reverse osmosis (RO) plant is proposed to be installed to meet potable water requirements.

The electrical power for the project will be generated by 900kVA diesel-powered generators onsite.

Access to the project site will be via the existing road linking Selingue to the Kobada Village. The road will be upgraded and a new bridge will be constructed across the Fie River, as part of the project.

Other major infrastructure at the site will include waste rock facilities, tailings storage facilities, fuel storage facilities, and buildings to house the offices, workshop, accommodation camps and medical facilities.

Key players involved

The PEA was compiled by International Resource Solutions, Gekko Systems, and John Dunlop & Associates. Gekko Systems was further involved in conducting the metallurgical testwork in collaboration with Bureau Veritas, as part of the DFS.