The Jervois Copper-Silver Project, solely owned by KGL Resources, is located approximately 380km north-east of Alice Springs, in the Northern Territory, Australia. The project site is accessible via the Stuart and Plenty highways.

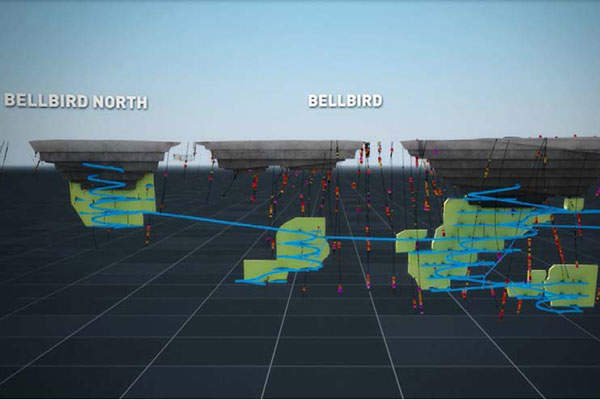

The project is located on the existing ML 30180 and ML 30182 mineral licences and another mineral licence application MLA 30829, within EL 25429, held by Jinka Minerals, a subsidiary of KGL Resources (formerly Kentor Gold). The mine hosts five deposits, namely Marshall-Reward (including Reward East and Sykes), Green Parrot, Bellbird (including Bellbird North), Rockface and Cox’s Find.

The pre-feasibility study (PFS) for the project was completed in December 2014 and updated in October 2015, while the front-end engineering and design (FEED) is expected to be initiated in the first quarter of 2017, and site works are expected to start in the third quarter of 2017.

Construction works for the project are expected to be completed in the third quarter of 2017 and first production is anticipated in late 2018. The project is estimated to involve an investment of $189.5m, including contingency provision.

Molyhil tungsten and molybdenum mine is located 220km from Alice Springs in the Northern Territory of Australia.

Jervois mine geology and reserves

The copper-lead-zinc mineralisation at Jervois is strata-bound in nature and has a strike length of approximately 12km, intercepting steeply dipping bodies of calc-silicate and garnet-chlorite-magnetite rocks, and garnet-magnetite quartzite, within andalusite-cordierite and quartz-sericite-magnetite meta-sediments (schists).

The project is estimated to hold indicated and inferred resources of 30.5Mt, containing 327,000t of copper, 22.6Moz of silver, 143,000t of lead and 47,000t of zinc.

As of October 2015, the probable reserves of copper ore stand at 8.4Mt, graded at 1.12% Cu, 0.20 g/t Au, 17.9g/t AG, 0.14% Pb and 0.14% Zn. Probable lead/zinc reserves stand at 444,000t, graded at 0.775g/y Cu, 0.13g/t Au, 45.49g/t Ag, 4.13% Pb and 1.72% Zn.

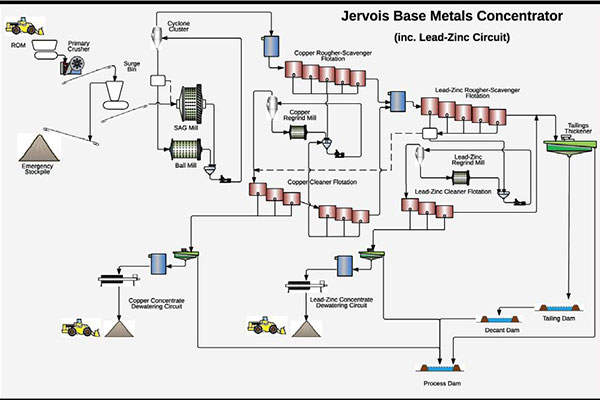

The project is estimated to produce 754,000t of copper concentrate at a grade of approximately 23% copper and 283g/t of silver during its initial estimated life of 8.25 years. The annual average production capacity is estimated to be 21,000t of contained copper and 1Moz of contained silver.

The project will also produce approximately 179,000t of bulk concentrate at a grade of 43% lead, 17% zinc and 1,069g/t silver.

Mining and processing at KGL’s copper-silver project

The mining method conceived for the project is open-pit, followed by underground.

For open-pit mining, the project will utilise a fleet of 90t trucks loaded by a Hitachi EX1900 shovel and a Hitachi EX1200 shovel for the first seven quarters, following which the Hitachi EX1900 will be decommissioned.

Underground mining will be introduced in the third year of operations, with long hole open stoping (LHOP) selected as the preferred method, while sub-level open stoping (SLOS) and benching methods are kept as alternative options.

The project will utilise twin-boom jumbos to develop the headings, 17t loaders (LHDs) will remove blasted rock from all development headings and stopes, and 50t trucks will transport the broken rock to the surface stockpile or waste dump. The production holes will be drilled by a large long-hole rig and the primary production fleet will be complemented by a dedicated charge-up unit, integrated tool carriers and a grader.

The proposed process plant is a conventional comminution circuit incorporating a primary crusher, a semi-autogenous grinding (SAG) mill and a ball mill operating in closed circuit with a cyclone cluster, designed to treat a variety of ore types. A pebble crusher is also proposed to be installed in the future.

Ore transport

The concentrates from the project will initially be trucked via the Plenty Highway to Alice Springs, sealed in half-height containers, and will be further transported by rail to either Darwin or Adelaide to be exported to Asia.

Infrastructure at Jervois mine

The existing infrastructure at the project site includes a run-of-mine (ROM) wall and the Jervois Mine Airstrip, which will be upgraded as part of the project.

The project will also involve the construction of additional infrastructure, including waste rock landforms, tailings storage facility, topsoil stockpiles, haul roads, heavy vehicle parking areas, ROM pads and fuel dumps, mine office and administration rooms, a plant control room, workshop, a warehouse, a laboratory, accommodation camp buildings, and a power station.

Key players involved with the Jervois project

H&S Consultants conducted the mineral resource estimates, the mining review was performed by Australia Mining Consulting, and Minelogix performed the metallurgical testwork.

Lycopodium was involved with the process plant and infrastructure design and engineering, including capital and operating cost estimates. Knight Piésold conducted the studies on tailings management and related infrastructure.

The geological studies and the environmental, social and permitting studies were conducted by KGL, whereas the transport and marketing studies were conducted by KGL in collaboration with Solutions Development.