The Florence copper project is an advanced-stage in-situ copper recovery (ISCR) project being developed in central Arizona, US. Project developer Taseko Mines acquired it from Curis Resources by puchasing all issued and outstanding common shares via a statutory plan of arrangement in November 2014.

The project is anticipated to produce more than 1.7 billion pounds of copper over its mine life of 21 years. It is estimated to produce an average of 81Mlb of copper a year.

The project is currently in advanced permitting stages for a production test facility, which, in addition to operation of the ISCR well field, will include an solvent extraction/electrowinning (SX/EW) plant to produce cathode copper.

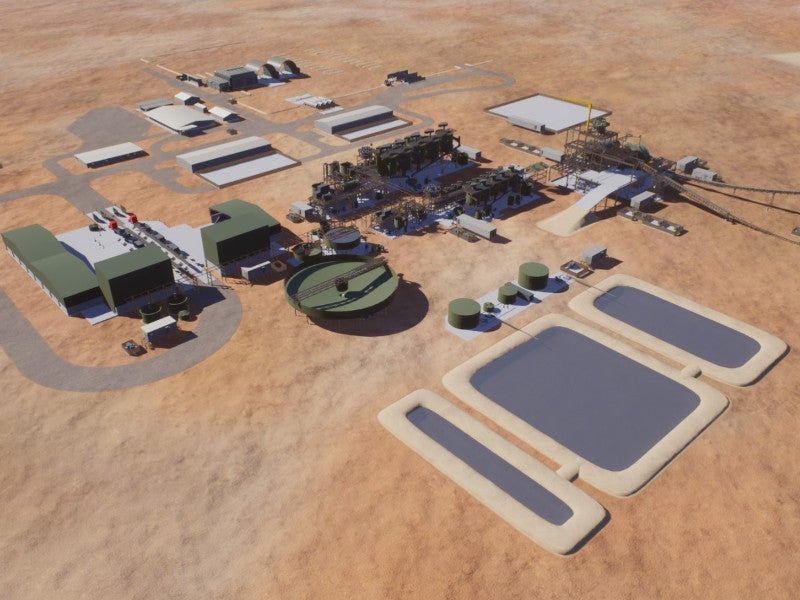

Details of the production test facility at the Florence project

The US Environmental Protection Agency (EPA) issued the inderground injection control (UIC) permit, which is required for the construction and operation of the Phase 1 Test Facility at the Florence copper project in December 2016.

The production test facility will include four injection wells, nine recovery wells, and 11 wells for groundwater monitoring.

The first phase of the test facility will include the manufacture of LME Grade A copper cathode; the drilling of wells, injection and recovery of the ISCR solution; as well as the observation and monitoring of groundwater quality and other environmental conditions.

Location, geology, and mineralisation of Florence copper project

Located within the American southwest copper belt, the copper project comprises a porphyry copper sulphide system below a thick and intensely fractured oxidised layer.

The deposit is believed to have formed approximately 62 million years ago due to an intrusion between dike swarms of Laramide granodiorite porphyry and Precambrian quartz monzonite near Poston Butte.

It is expected that the deposit was subjected to mid-Tertiary Basin and Range faulting and subsequent erosion, thereby burying the entire deposit to a depth of approximately 375ft. During the latter period, calcareous silt mud and clay layers are believed to have deposited in shallow basins.

The mineralised zones consist of an iron-enriched leached cap, an oxide zone and an underlying sulphide zone. A majority of the copper oxide mineralisation is located along fracture surfaces, but chrysocolla and copper-bearing clay minerals also replace feldspar minerals in the granodiorite porphyry and quartz monzonite.

The main type of mineralisation is oxide with underlying sulphide separated by a transition oxidation zone.

Florence copper project reserves

The Florence copper mine is estimated to contain probable reserves of 345Mt of ore containing 2.47 billion pounds of copper.

Mining and processing of ore from the Florence copper mine

The in-situ recovery (ISR) mining method has been proposed for the project. The equipment used for ISR includes wells, pumps and pipelines that inject, recover and convey process solutions.

The ISCR process selected for the project involves the installation of injection and recovery wells to pass a weak sulphuric acid solution called raffinate through targeted portions of the mineral deposit.

Raffinate dissolves the copper mineralisation, and the copper laden solution, known as pregnant leach solution, is collected in recovery wells. The leach solution is then pumped to the surface for processing by solvent extraction and electro-winning.

The SX plant will be located to the east of the process ponds and comprise four mixer-settlers and other associated facilities. It will be capable of handling the leach solution at flow rate of 11,000gpm with a PLS grade of 2g/l.

The electro-winning plant will comprise two parallel banks of 50 cells equipped with permanent cathode blank technology.

The SX/EW plants remove copper from the leach solution, as well as recover raffinate solution, to be recirculated to the well field.

Infrastructure facilities at the Florence project

Access to the copper mine is from Hunt Highway, two miles west of US Highway 79 north of Florence, Arizona. The project is also in close proximity to the Copper Basin Railroad, which is located just north of Hunt Highway.

Power supply for the mine is proposed to be made from Arizona Public Service Electric (APS) via a 69kV transmission line situated at the northwest corner of the site.

Potable water is available onsite from an existing water supply well and potable water treatment plant. For process and fire suppression water, a pipeline will be constructed from the existing well to the process/firewater storage tank.

Southwest Gas will supply natural gas for the mine from its Poston Butte Loop located approximately one mile to the east of the site. For the project, a 4in main pipeline will have to be constructed to the property entrance along with a 2in distribution pipeline to the plant site.

Offtake of copper produced at FCP

Curis Resources entered an off-take agreement with RK Mine Finance Trust I (Red Kite) for 19% of the copper production at Florence mine. The off-take agreement was made in exchange for a $40m investment provided by Red Kite under a senior secured bridge loan facility for the project development.

The remaining copper cathode will be either sold in the open market or through off-take arrangements, which is yet to be determined.